Punching and bookbinding machine

A binding machine and frame technology, applied in binding, metal processing, etc., can solve the problems of paper scraps being difficult to discharge, easy to block, and broken knives, and achieve the effects of not being easy to block, coherent and convenient to use, and smooth to discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

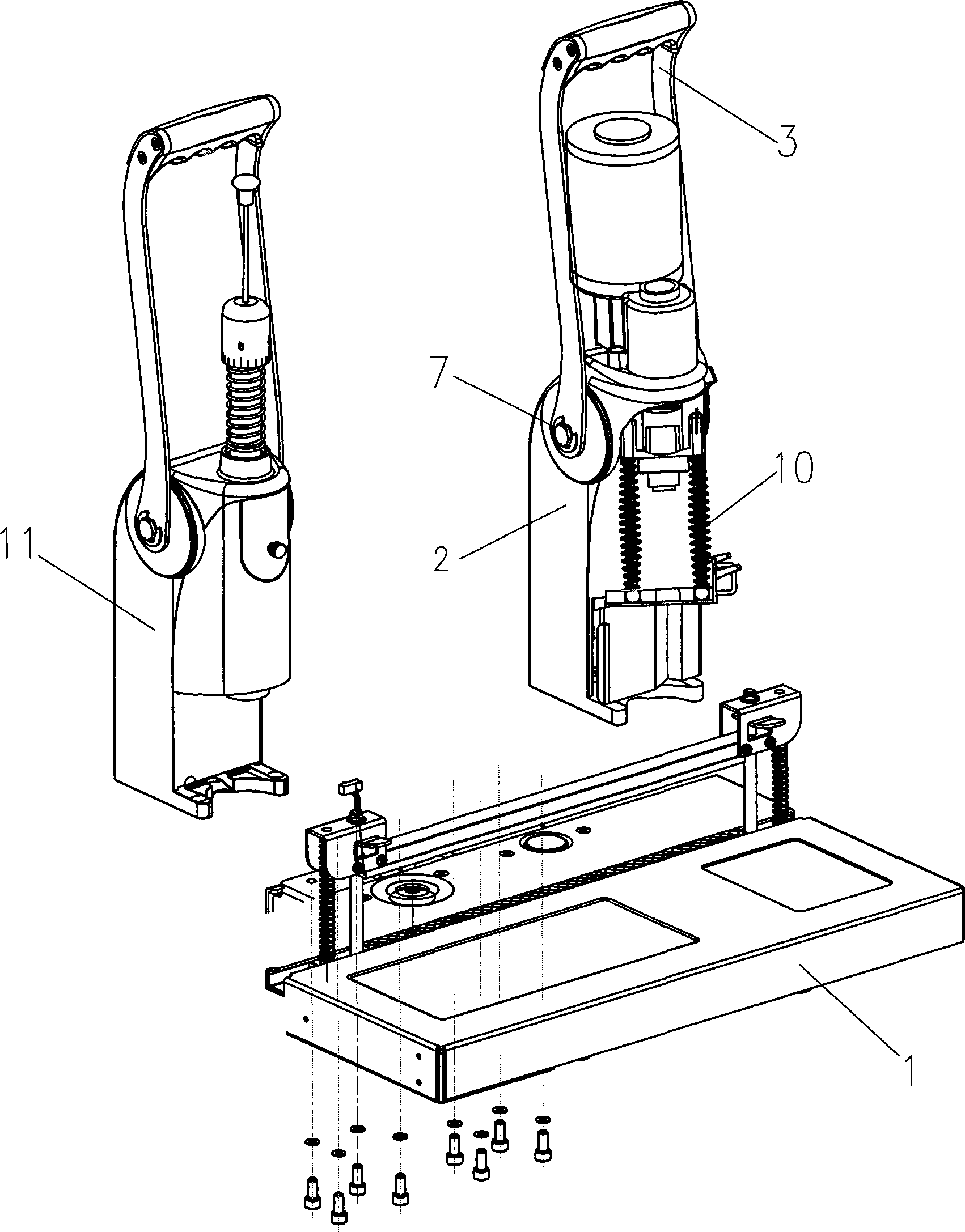

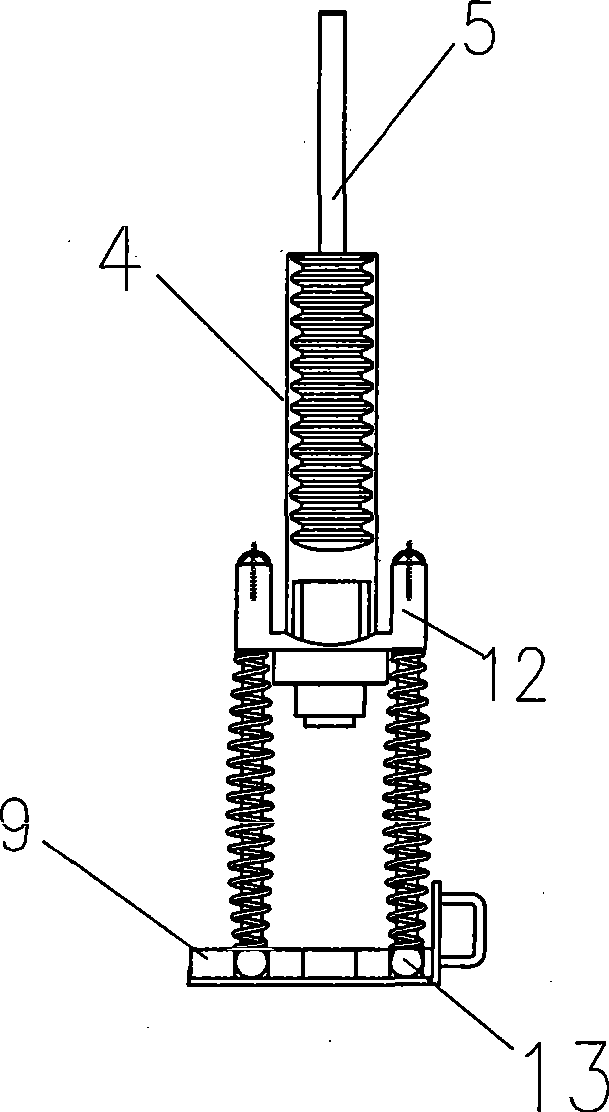

[0023] refer to Figure 1-4 : punching and binding machine, comprising a punching mechanism, the punching mechanism includes a base 1, a frame 2 installed on the base 1, an operating handle 3 hinged with the frame 2, and the operating handle 3 passes through The intermediate mechanism is connected with a guide post 4 that can slide up and down. The drill bit assembly connected to the drive motor is pierced in the guide post 4. There is an axial chip removal channel in the drill bit assembly. The guide post 4 The lower end is connected with a paper pressing mechanism, and the upper end of the drill bit assembly is provided with a guiding mechanism that guides the paper scraps from the axial direction to the radial direction. The outlet corresponds to the opening 7 .

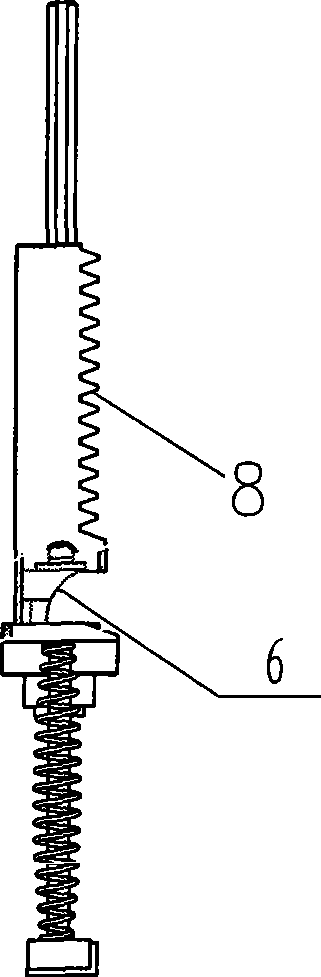

[0024] The guide mechanism is a guide groove 6 along the outer wall of the guide post 4 that smoothly communicates downward with the upper port of the chip removal channel.

[0025] The lower port of the guide g...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment lies in that: the guide rod is connected to the pressboard through a ball hinge 13, and the pressboard has a ball seat corresponding to the ball hinge. The spherical hinge is fixedly connected with the lower end of the guide rod. The ball seat is arranged inside the pressboard.

[0034] Other structures and implementations of this embodiment are completely the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com