LED flexible neon lamp strip

A technology of LED lamps and neon lights, which is applied in the direction of electric lamp circuit layout, lighting and heating equipment, instruments, etc., can solve the problems of cumbersome processing technology, complex structure, large power consumption, etc., achieve continuous and uniform illumination, simple processing technology, Product cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

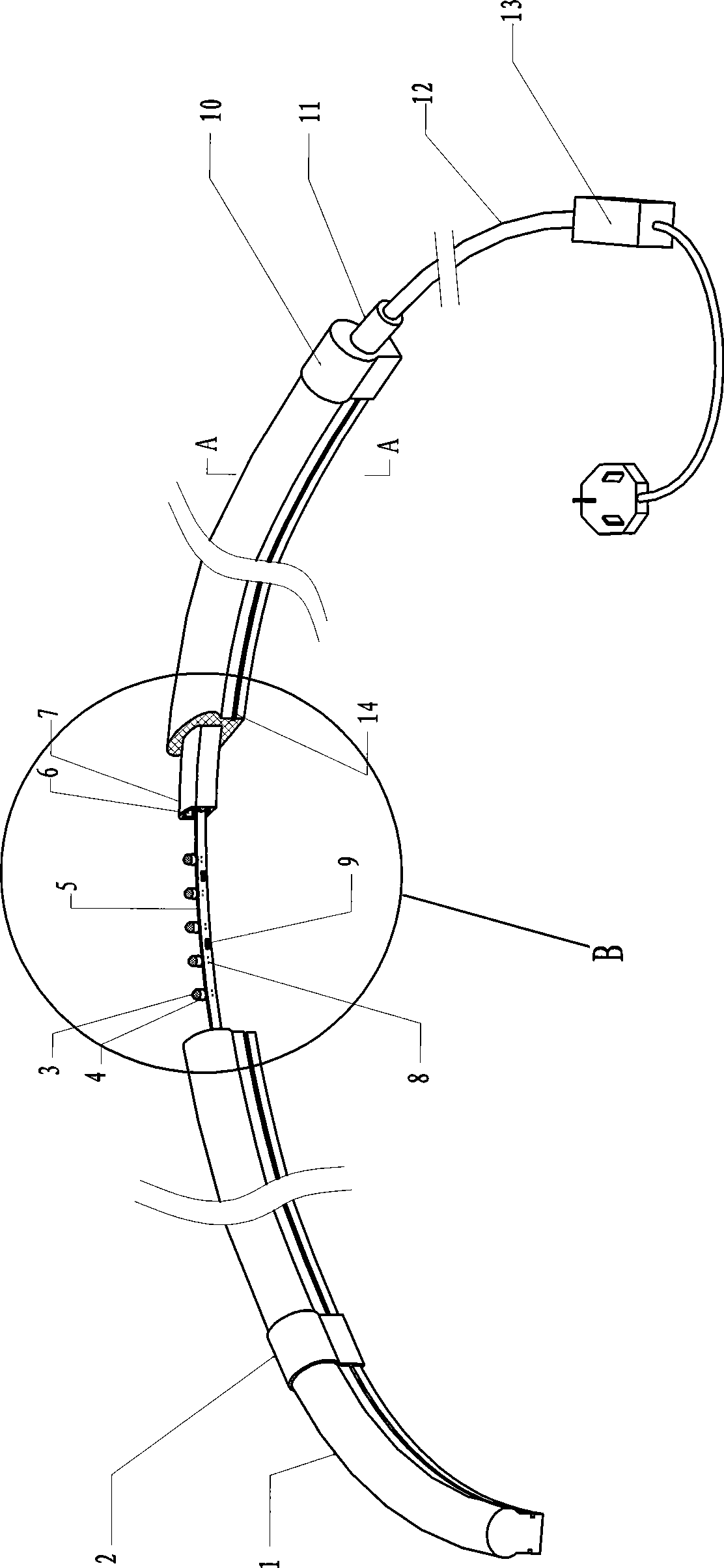

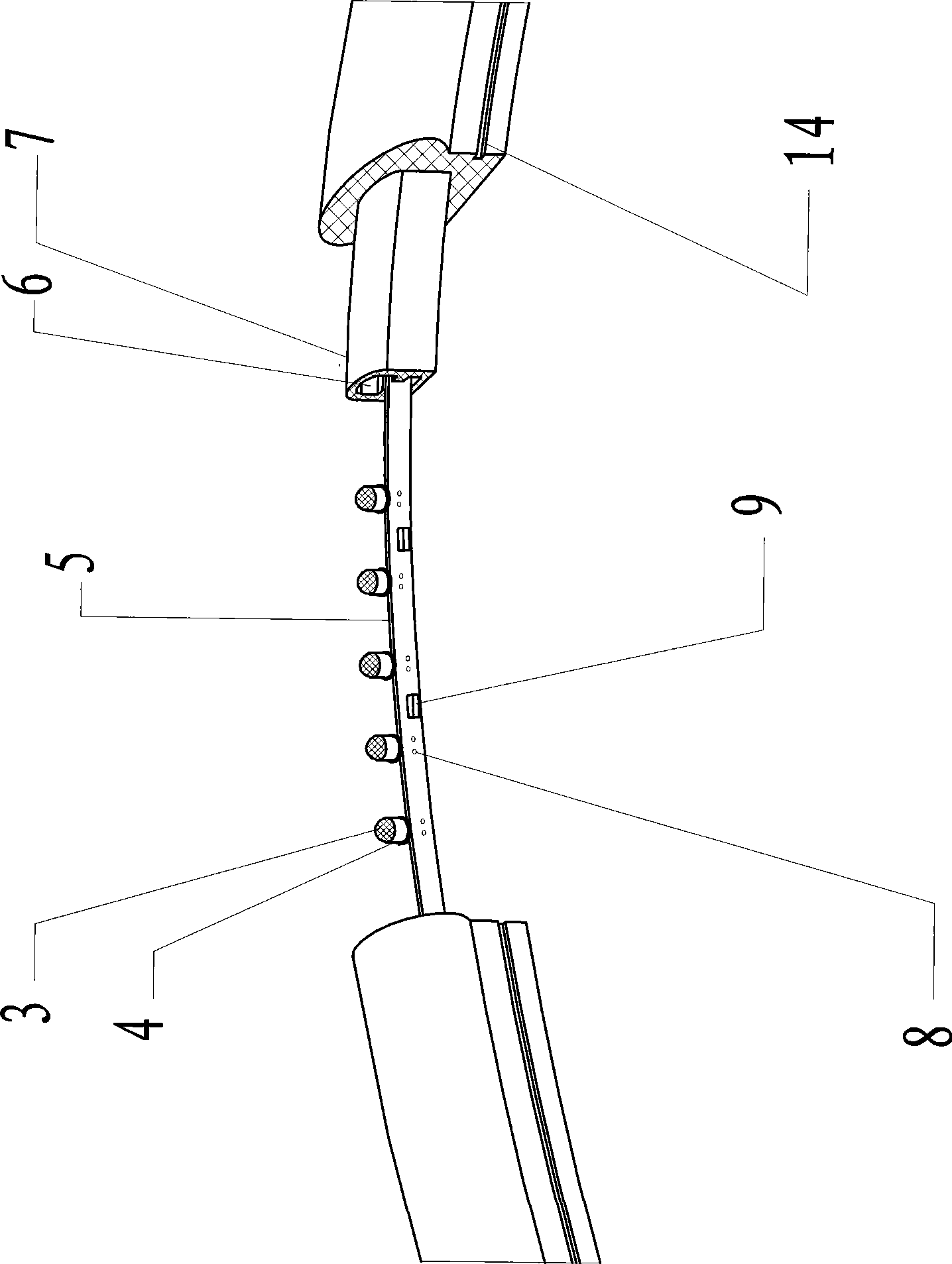

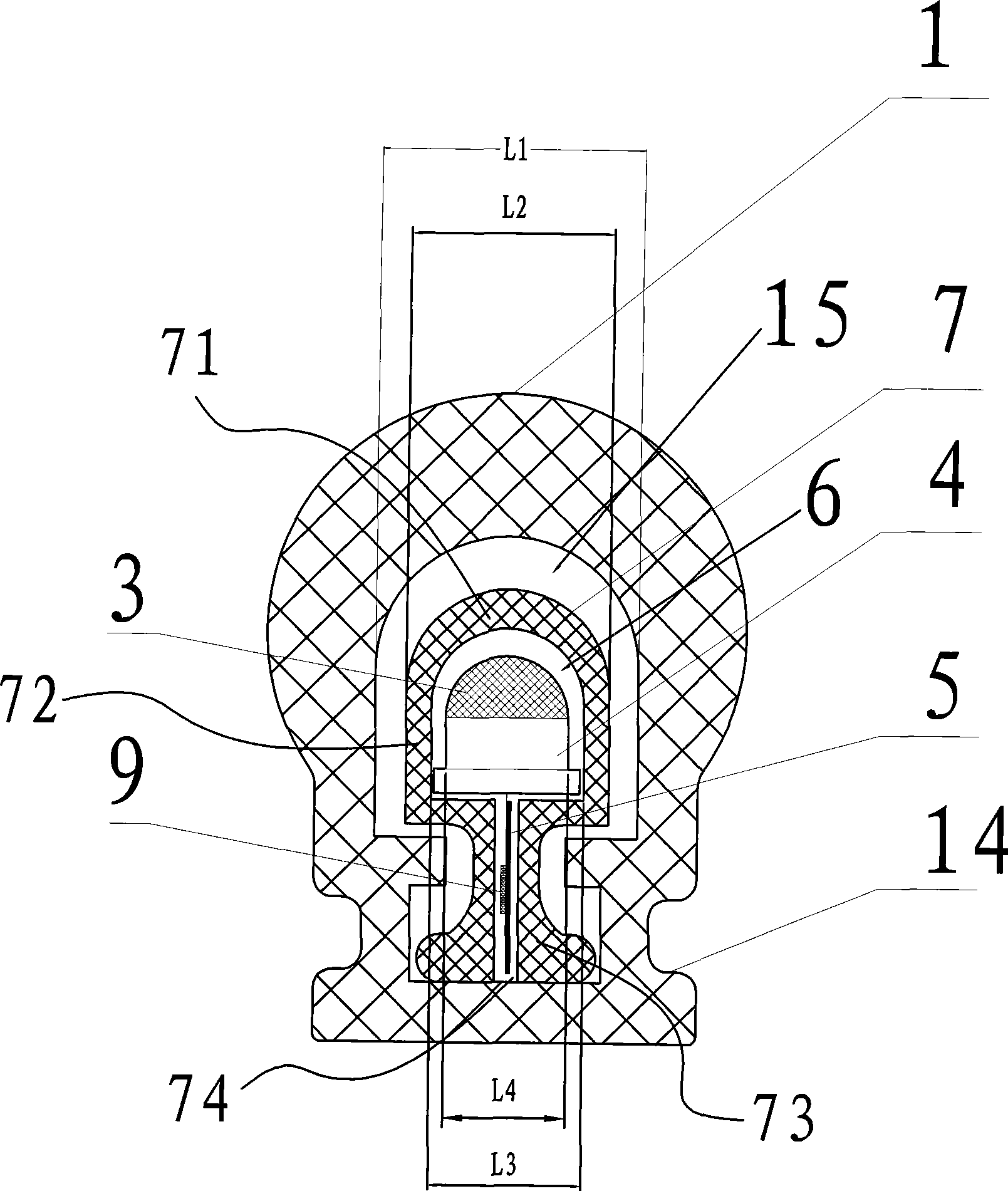

[0035] Example 1, see figure 1 — image 3 , at 7-11. The LED flexible neon light strip of this embodiment includes:

[0036] An FPC flexible circuit board 5, the FPC flexible circuit board 5 includes a layer of insulating film and a copper foil pressed together with it, the copper foil is printed with a circuit connecting the LED lamp and the current limiting resistor, and the circuit forms an electrical circuit ;

[0037] A plurality of LED lights 4, the two pins of these LED lights 4 are parallel to the FPC flexible circuit board 5, and are connected in series to the circuit of the above-mentioned FPC flexible circuit board 5;

[0038] A plurality of current-limiting resistors 9, each current-limiting resistor 9 is welded on the circuit of the FPC flexible circuit board 5 in parallel with the FPC flexible circuit board 5, and at least one current-limiting resistor 9 is connected in series between every three LED lamps 4;

[0039] Translucent light guide strip 7, the ligh...

Embodiment 2

[0048] Example 2, see Figure 4 —6. In this embodiment, on the basis of the above-mentioned embodiments, a light bar clamping groove 14 is provided at the bottom of the semi-conductive colloid coat 1, and there is also a connecting terminal 2 whose shape is similar to that of the semi-conductive colloid coat 1. The core is provided with a clamping plate 21 that matches the above-mentioned lamp bar clamping slot 14, and also has a longitudinal clamping slot 22 that matches the height and thickness of the FPC flexible circuit board 5, and one side of the clamping slot 22 is provided with a positive electrode Line 16a and negative pole line 16b, the positive pole line and negative pole line are respectively contacted and connected with the positive and negative poles of the circuit on the FPC flexible circuit board 5, and the connecting terminal 2 is installed between the terminals of two LED flexible neon light strips.

[0049] In addition, when installing the LED flexible neon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com