Radiator for high-power LED lamp

An LED lamp, high-power technology, applied in electric solid-state devices, semiconductor devices, lighting and heating equipment, etc., can solve the problems of shortening the life of LED lamps, not easy to dissipate heat, and bulky lamps, so as to improve market competitiveness, Reduce cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

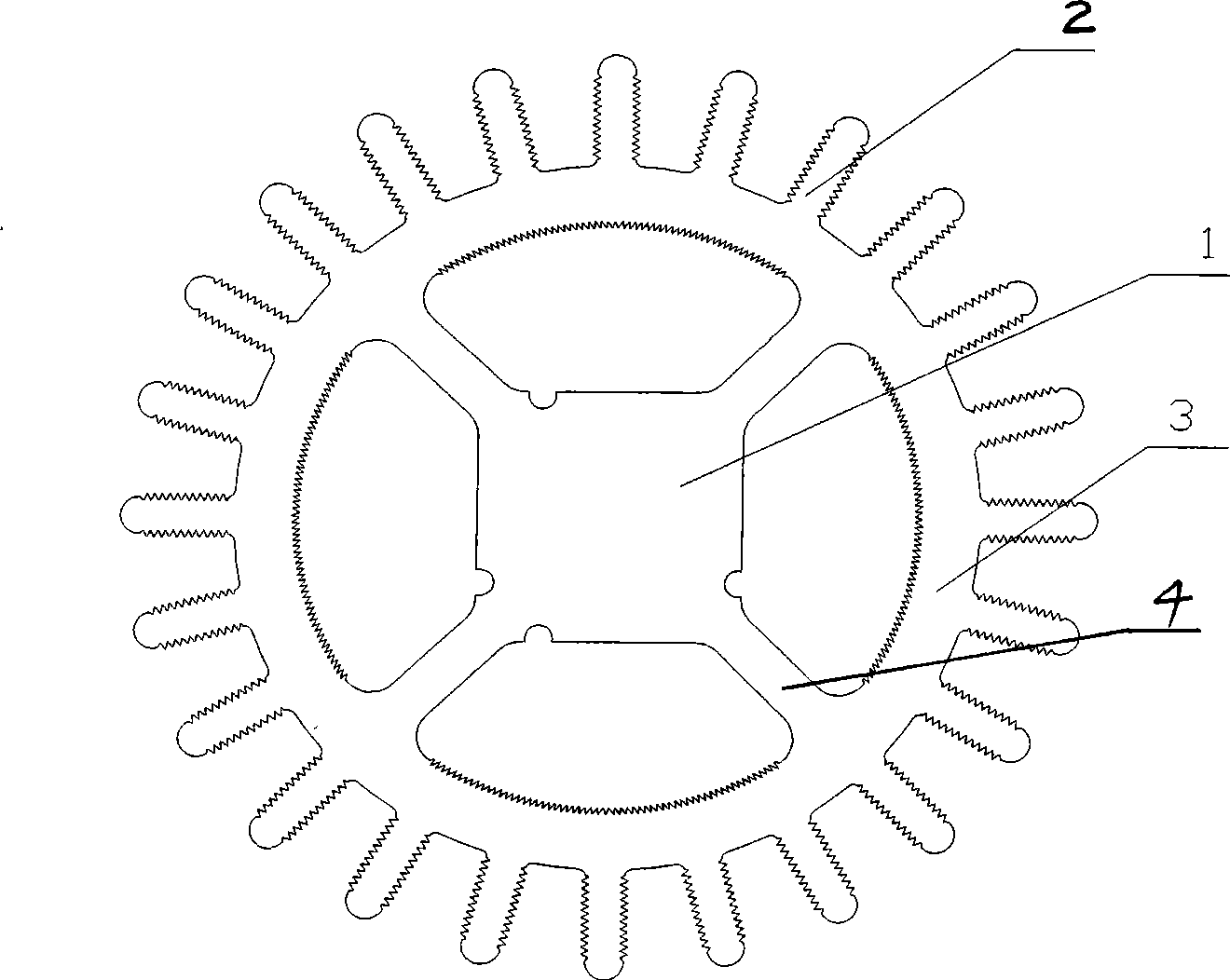

[0010] A heat sink for high-power LED lamps, including a heat dissipation substrate 3 and a plurality of heat dissipation fins 2 on it, the heat dissipation substrate 3 is in the shape of a cylindrical ring, and the outside of the cylindrical ring-shaped heat dissipation substrate 3 is evenly distributed with multiple groups of straight-toothed heat dissipation fins. The fins 2 and both sides of the heat dissipation fins 2 are provided with serrated grooves, and the inner center of the cylindrical ring-shaped heat dissipation substrate 3 is provided with a heat dissipation base 1 for installing a high-power LED light source. The heat dissipation base 1 is connected with the heat dissipation The substrate 3 is connected by a plurality of heat dissipation ribs 4 , and the shape of the heat dissipation base 1 matches the aluminum substrate of the high-power LED, and is usually designed as a circle or a square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com