High-temperature heating equipment used for orientation texture measurement

A high-temperature heating and texturing technology, which is applied in the direction of material analysis using radiation diffraction, etc., can solve the problems of inability to complete x-rotation and high-temperature measurement, and inability to complete measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

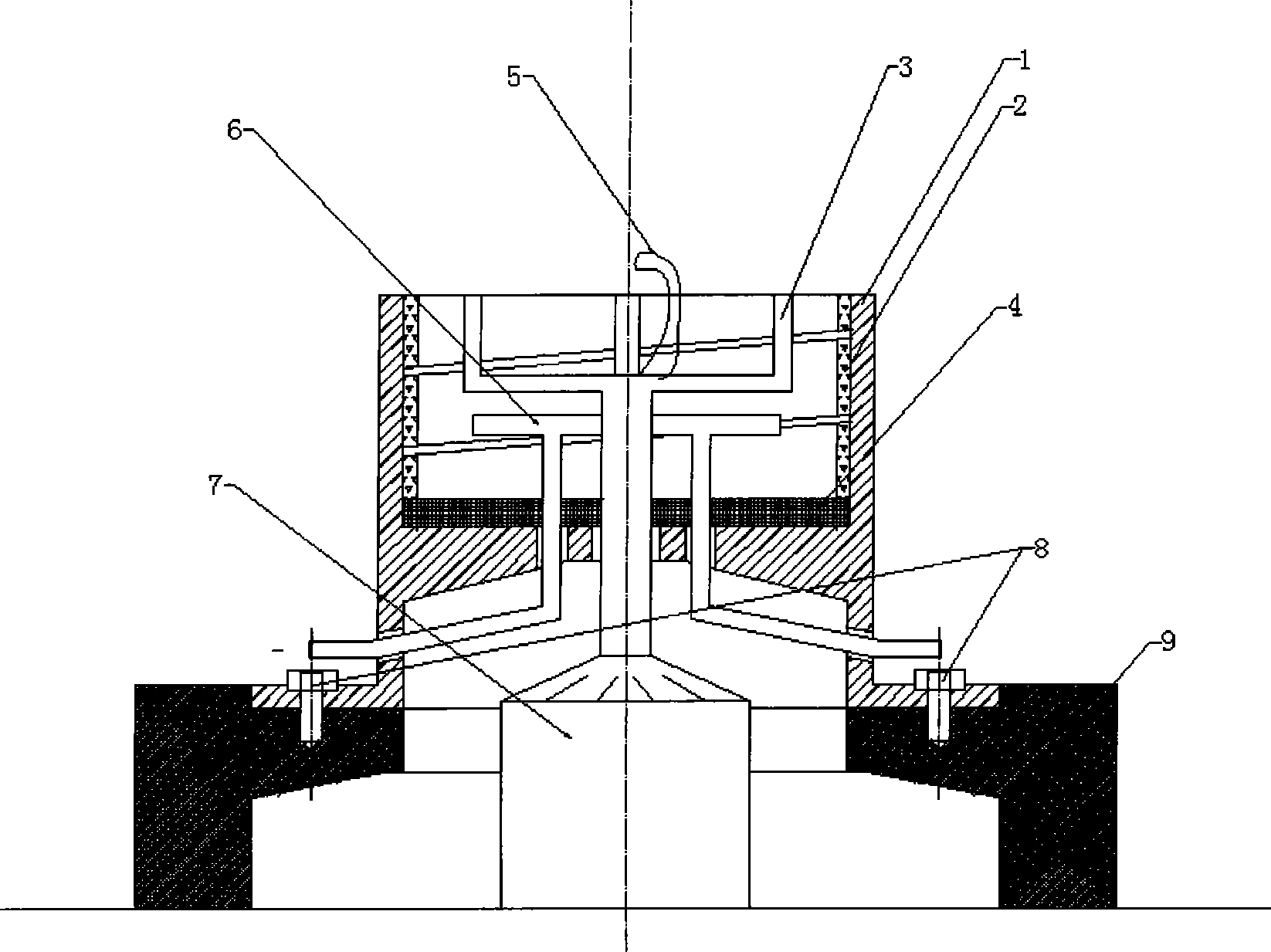

[0018] Such as figure 1 As shown, the measurement device involved in this embodiment includes a heating furnace body (not shown in the figure), a heating element 2, a sample holder 3, a thermocouple 5, a water cooling pipeline 6, a stepping motor 7, a sample stage base 9, and a heating element 2. The outside of the furnace body is a ceramic seat cover 1, embedded with a heating element 2, and the heating furnace body is set on the base of the sample table 9; the sample holder 3 is placed in the stepping motor 7, separated from the heating furnace body, and can be wound in the heating furnace body Its own axis rotates, which on the one hand completes the φ rotation in the texture measurement, and on the other hand makes the sample evenly heated; the lower part of the sample holder 3 has a water cooling pipeline 6, which is coiled parallel to the lower surface of the sample to form a cooling plane; the heating furnace There is a thermocouple 5 in the body in contact with the bot...

Embodiment 2

[0027] The installation of the sample is the same as in Example 1. The heating element 2 adopts an electric heating coil or an electric heating tube, and the heating temperature can reach 500-800 degrees. The rotation realizes the ψ tilt in the roll stress measurement method (the two have a relationship of x=90°-ψ).

[0028] The specific steps are: the tested sample is placed on the sample holder 3, confirm that the diffraction center is in the sample surface plane, and select a specific 2θ value (usually in the range of 110-160°, such as for ordinary carbon steel) according to the crystallographic characteristics of the tested sample The sample is measured at 156° when the CrK α radiation source is used), the detector and the light pipe are turned to the corresponding angular positions, and the heating device is started at this time, and the stress measurement of the roll method is started when the preset temperature is reached. In ψ=0°, ±15°, ±25°, ±30°, ±35°, ±40°, ±45°, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com