Energy-saving seedling cultivation greenhouse

A seedling-growing greenhouse and energy-saving technology, applied in the field of greenhouses, can solve problems such as increasing the environment, high cost, pollution, etc., and achieve the effects of reducing labor intensity, reducing operating costs, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

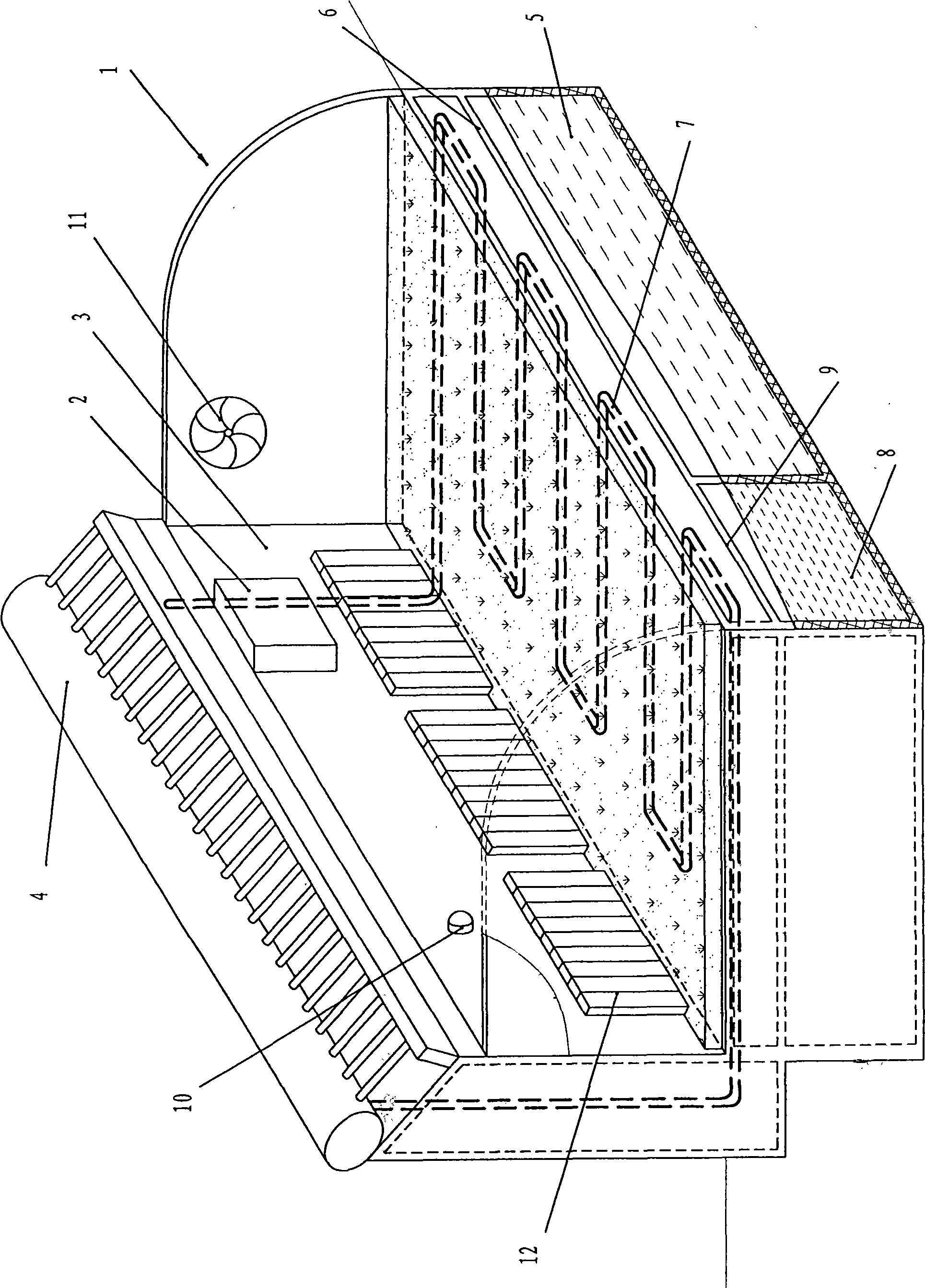

[0013] Such as figure 1 As shown, the energy-saving seedling-raising greenhouse of the present invention comprises a shed room 1, and the rear portion of the shed room 1 has an insulating wall 3, and the top of the insulating wall 3 is provided with a solar water heater 4. There is a set of radiators 12, a hot water reservoir 5 is provided below the ground level of the shed 1, a cover plate 6 is laid on the top of the hot water reservoir 5, and a heat dissipation pipe is coiled in the soil layer above the cover plate 6 net 7,

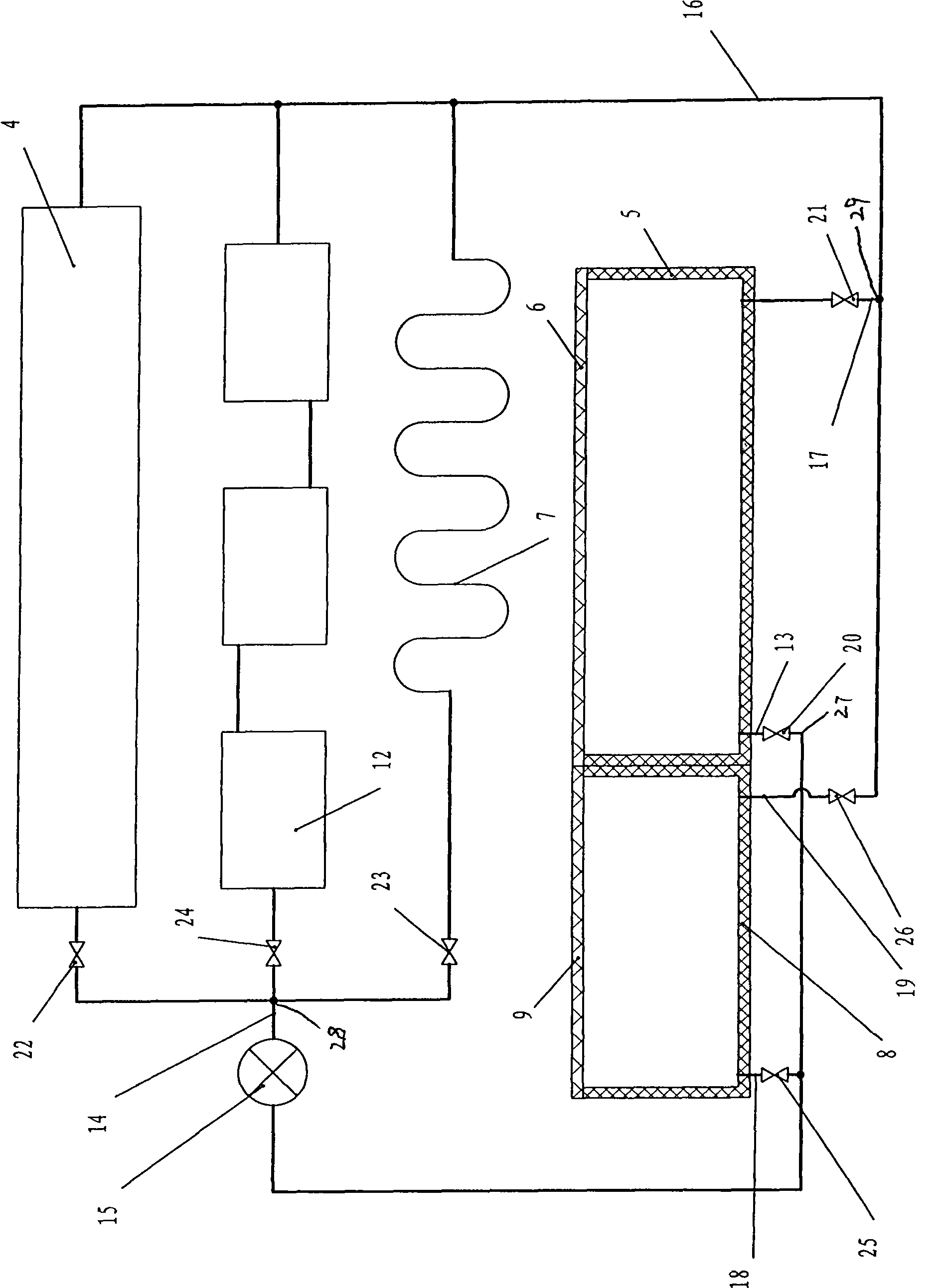

[0014] Such as figure 2 As shown, the left end of the hot water reservoir 5 is connected with a hot water outlet pipe 13, and the middle part of the hot water outlet pipe 13 is connected with an electric cut-off door 20 in series, and the water outlet 27 of the hot water outlet pipe 13 is connected with the water inlet of the water delivery pipe 14 , on the water delivery pipe 14, there is a circulation pump 15 connected in series, and an electric he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com