Machine for hulling green pericarp of walnut

A walnut green peeling and shelling machine technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of unclean peeling of small fruits, unclean peeling of walnut fruits, and easy crushing of large walnut fruits. , to achieve the effect of light weight, saving labor and time, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

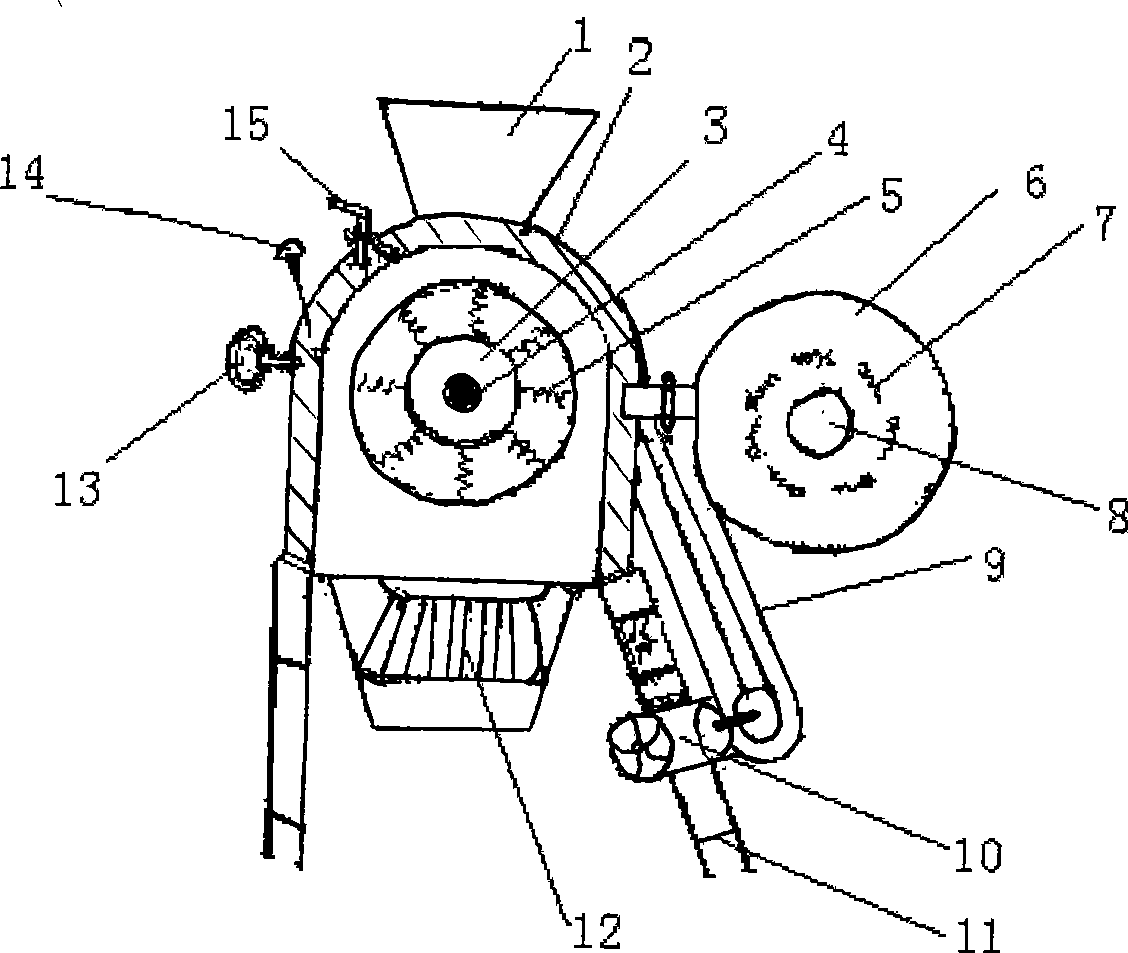

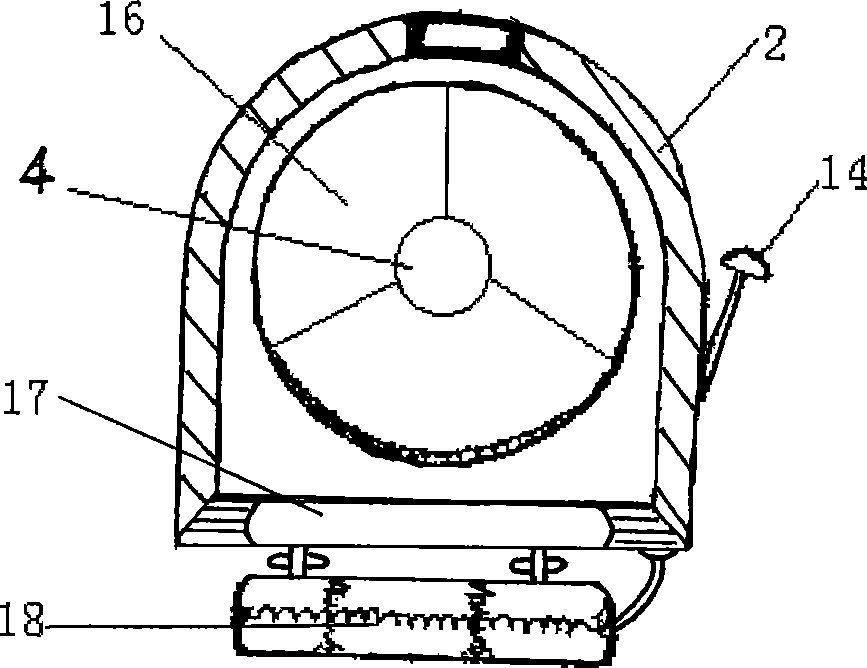

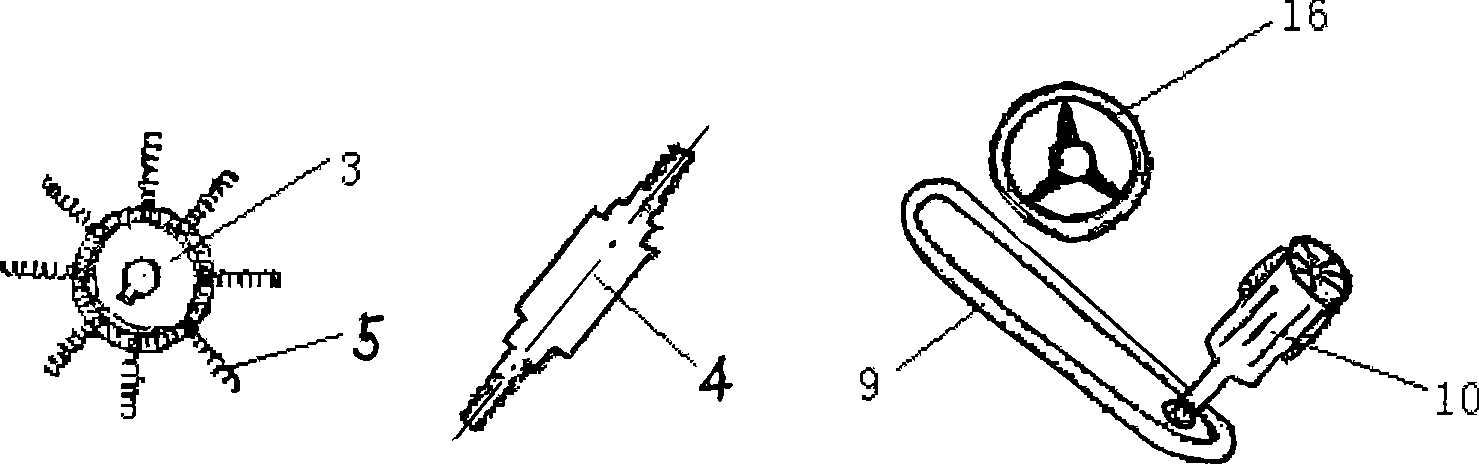

[0014] now attached Figure 1~3 The present invention is further described. A feed hopper is installed on the top of the casing, and a discharge port is arranged below. A number of rotating steel wires or similar objects connected to the rotating disk are installed inside the casing. The rotating disk is installed on the transmission shaft. Fixed wire on the inside wall of the cabinet or on the access door. Transmission shaft is equipped with rotating disk on one section in the casing, and some rotating steel wires or the like are housed on the rotating disk, and transmission wheel is housed on the section of transmission shaft outside the casing, and casing is placed on the support. The green-skinned walnuts put in from the feed hopper are removed and crushed from the walnut fruit by the beating of the fixed steel wire and the rotating steel wire. Because the steel wire has elasticity, the walnut fruit will not be broken, but only the walnut green skin is removed and crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com