Improved vacuum-sulfurizing, bottom-sticking, freezing-moulding technique for processing boots and device thereof

A processing technology and vacuum technology, applied in the direction of shoe-making machinery, footwear, adhesive shoe parts, etc., can solve the problems of not complying with energy saving, increasing costs, and failing to achieve energy-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

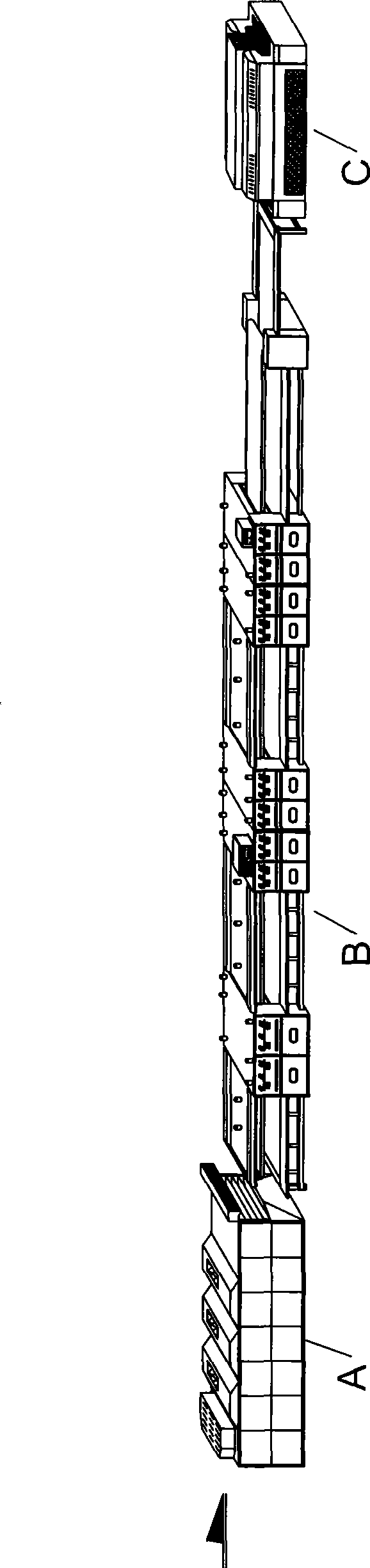

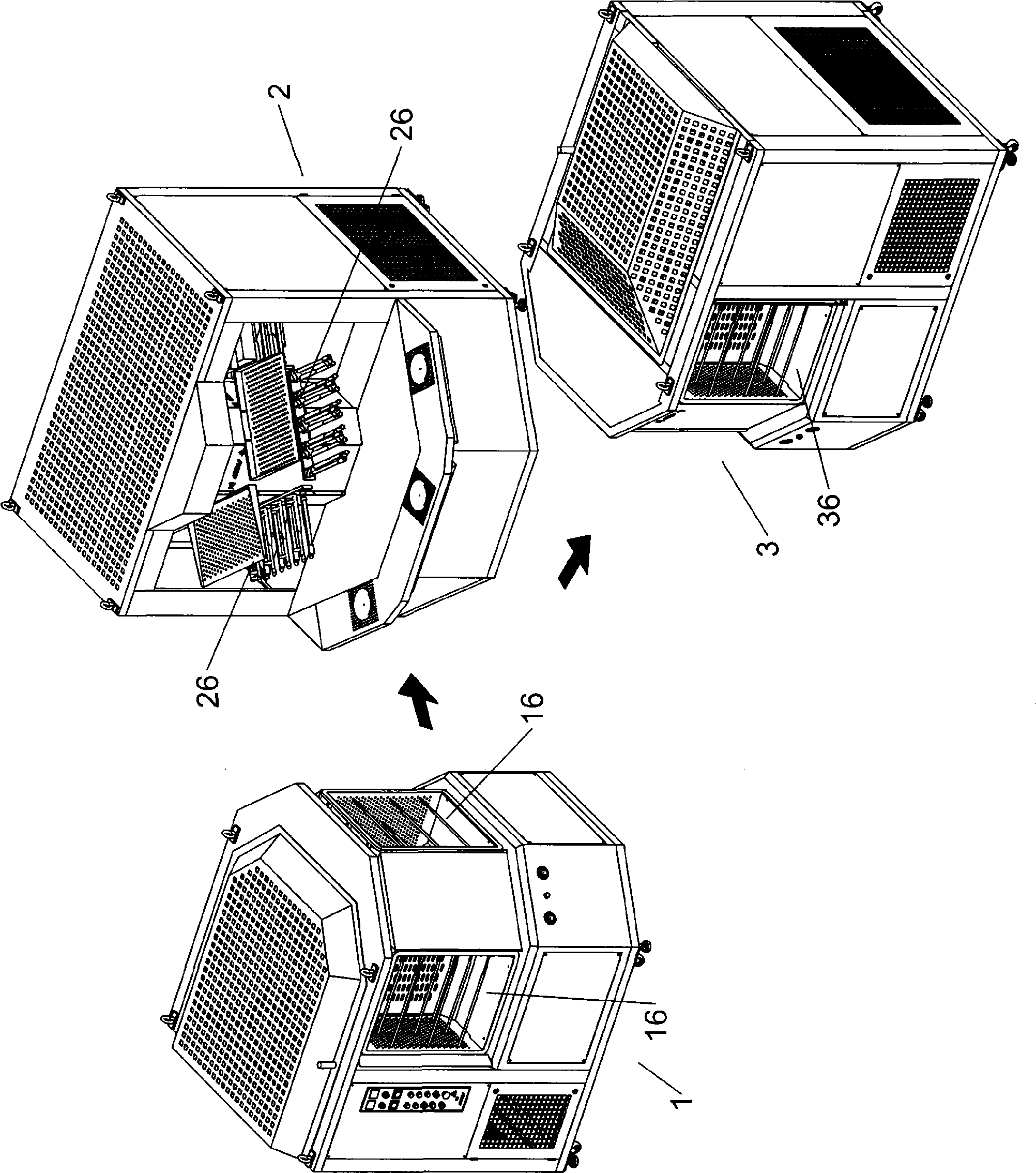

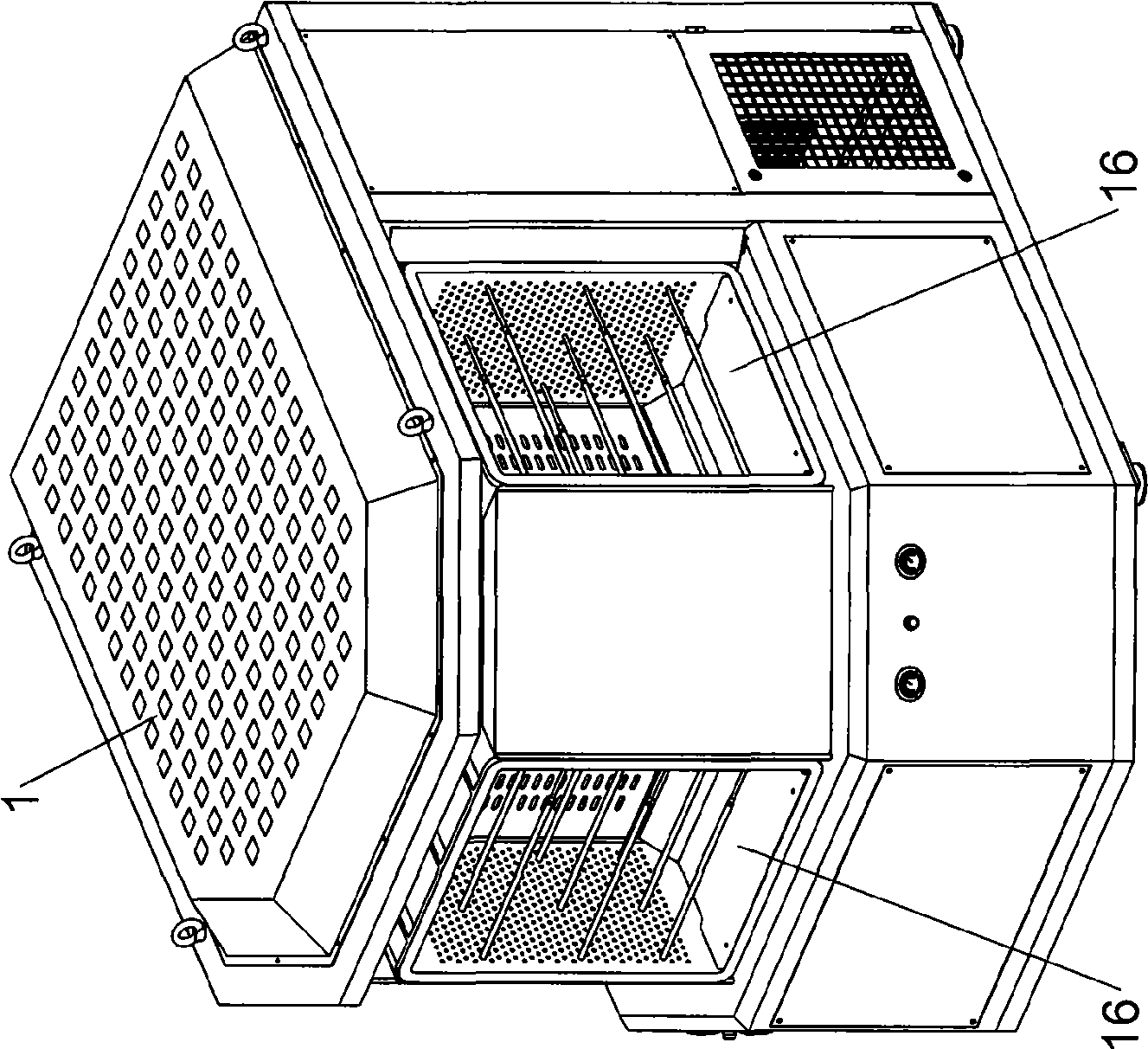

[0031] The present invention is in existing shoe production line (as figure 1 ) of the vulcanizing machine A, drying machine B, freezing and setting machine C conveyor belt transmission mode reform; please refer to figure 2 - Figure 5 with image 3 A~ Figure 3D , Figure 4A ~ Figure 4C , Figure 5A~ Figure 5D As shown, a vacuum vulcanizer 1 (such as image 3 ) is located at the forefront of the shoe production line (such as figure 2 ), see image 3 A~ Figure 3D , using a motor 11 with a reduction gear box 12 to drive the rotating shaft 13, and a plurality of vacuum vulcanization boxes 16 are fixed on the periphery of the upper and lower turntables 14 and 15, and at a specific working position of the plurality of vacuum vulcanization boxes 16, When the vacuum vulcanization box 16 is transferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com