Robot joint drive system

A driving device and robot technology, applied in the direction of electromechanical devices, transmission devices, gear transmission devices, etc., can solve the problems of undisclosed motor and reducer storage, and achieve the effect of reducing the occupied volume and easy inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

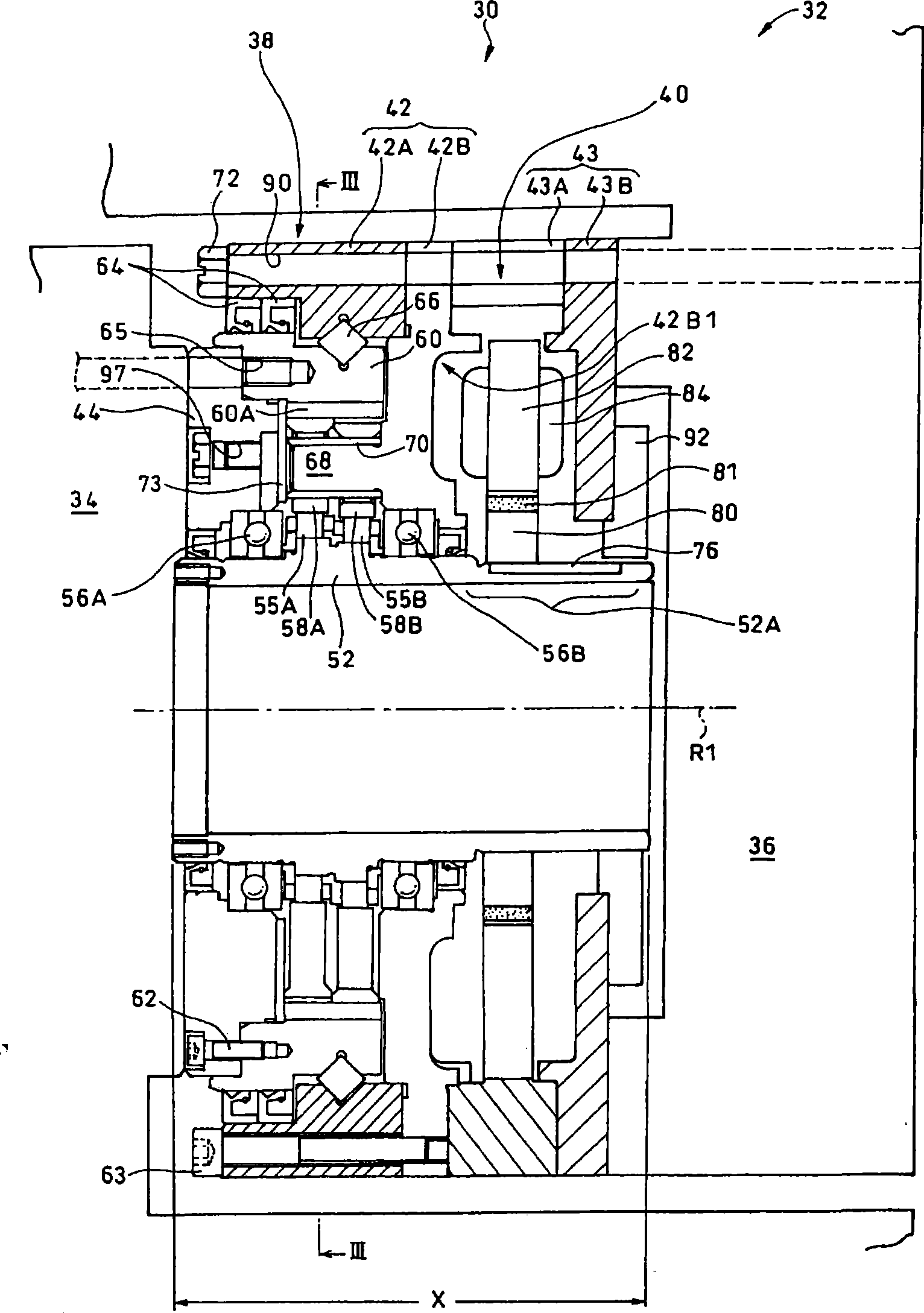

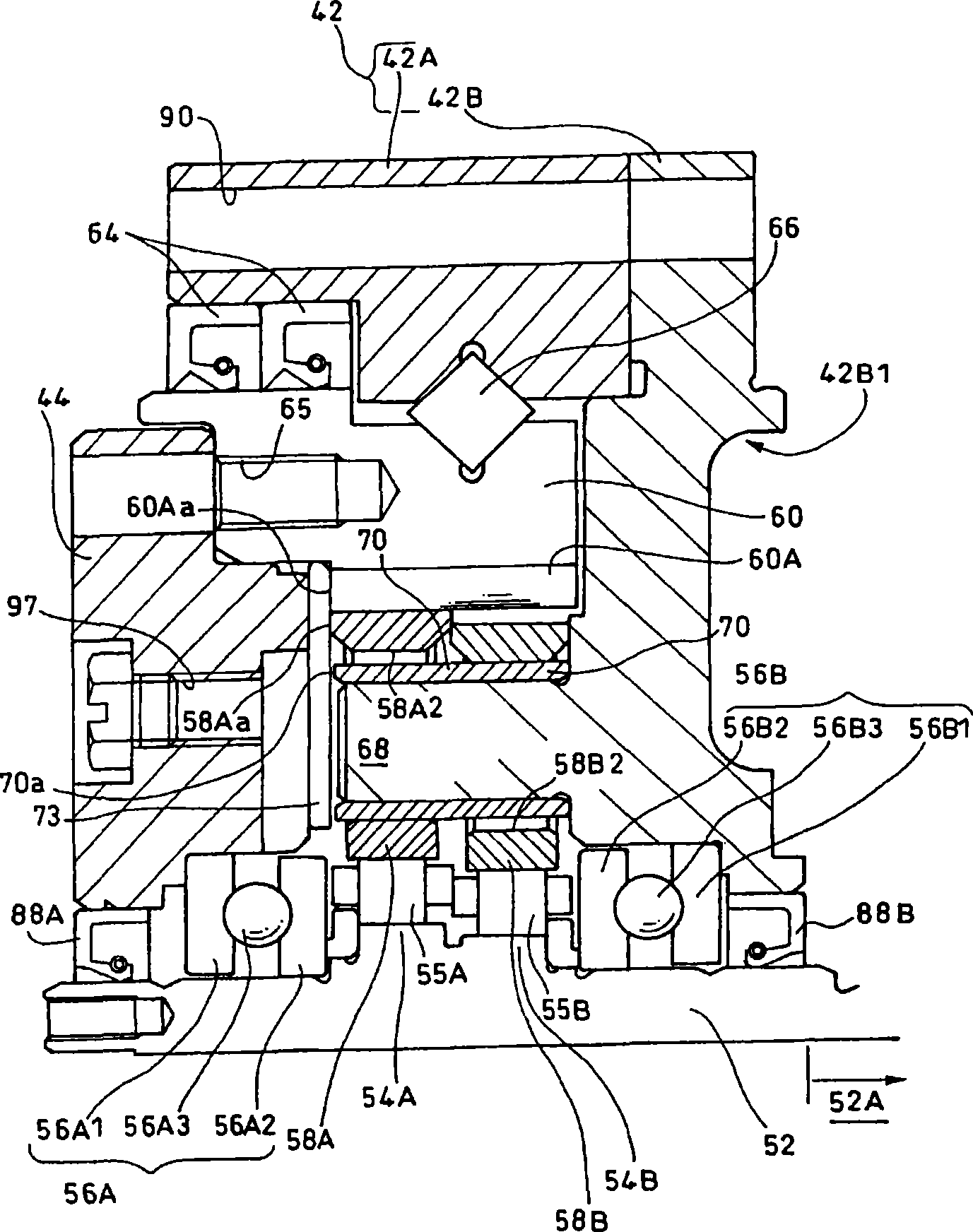

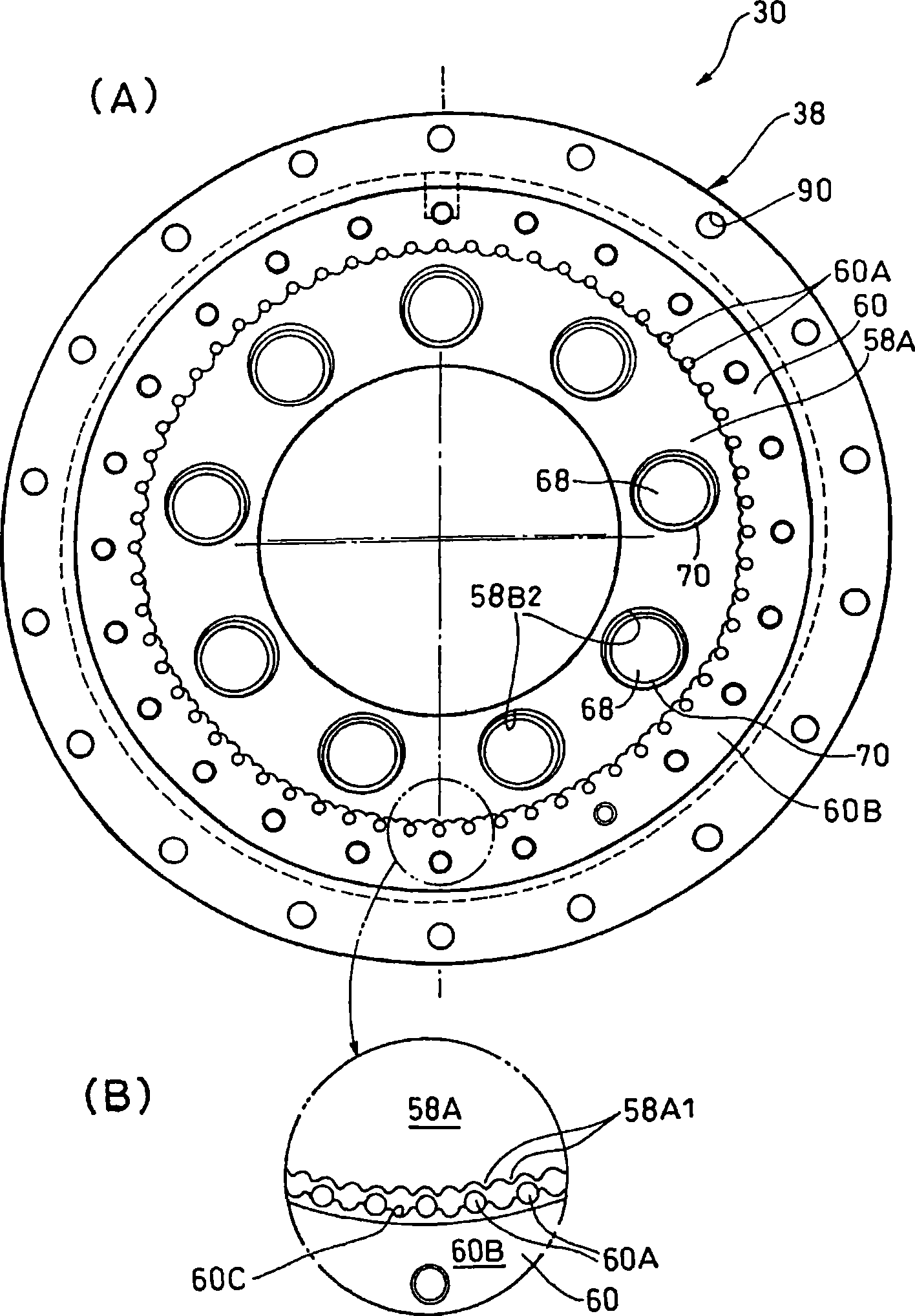

[0021] Hereinafter, an example of an embodiment of the present invention will be described in detail with reference to the drawings.

[0022] First, refer to Figure 4 The overall structure will be described in general. Figure 4 It is a schematic plan view and a side view showing a case where a robot joint drive device according to an example of an embodiment of the present invention is used for a robot arm.

[0023] This robot joint driving device 30 has a speed reducer 38 and a flat motor 40, and drives a first member 34 and a second member 36 of an arm 32 of a robot (not shown in its entirety) to rotate relative to each other. The first member 34 is fixed to an output flange (output shaft) 44 of the speed reducer 38 . The speed reducer case 42 is fixed to the second member 36 via the motor case 43 . The output flange 44 of the speed reducer 38 is relatively rotatable around the rotation axis R1 with respect to the speed reducer case 42 . Therefore, as a result, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com