Synchronous collection and conversion device for wave kinetic potential

A conversion device and technology of potential energy are applied in the field of wave kinetic potential energy synchronous collection and conversion device, which can solve the problems of insufficient collection and utilization of wave energy, and achieve the effects of simple structure, low requirements on manufacturing precision and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

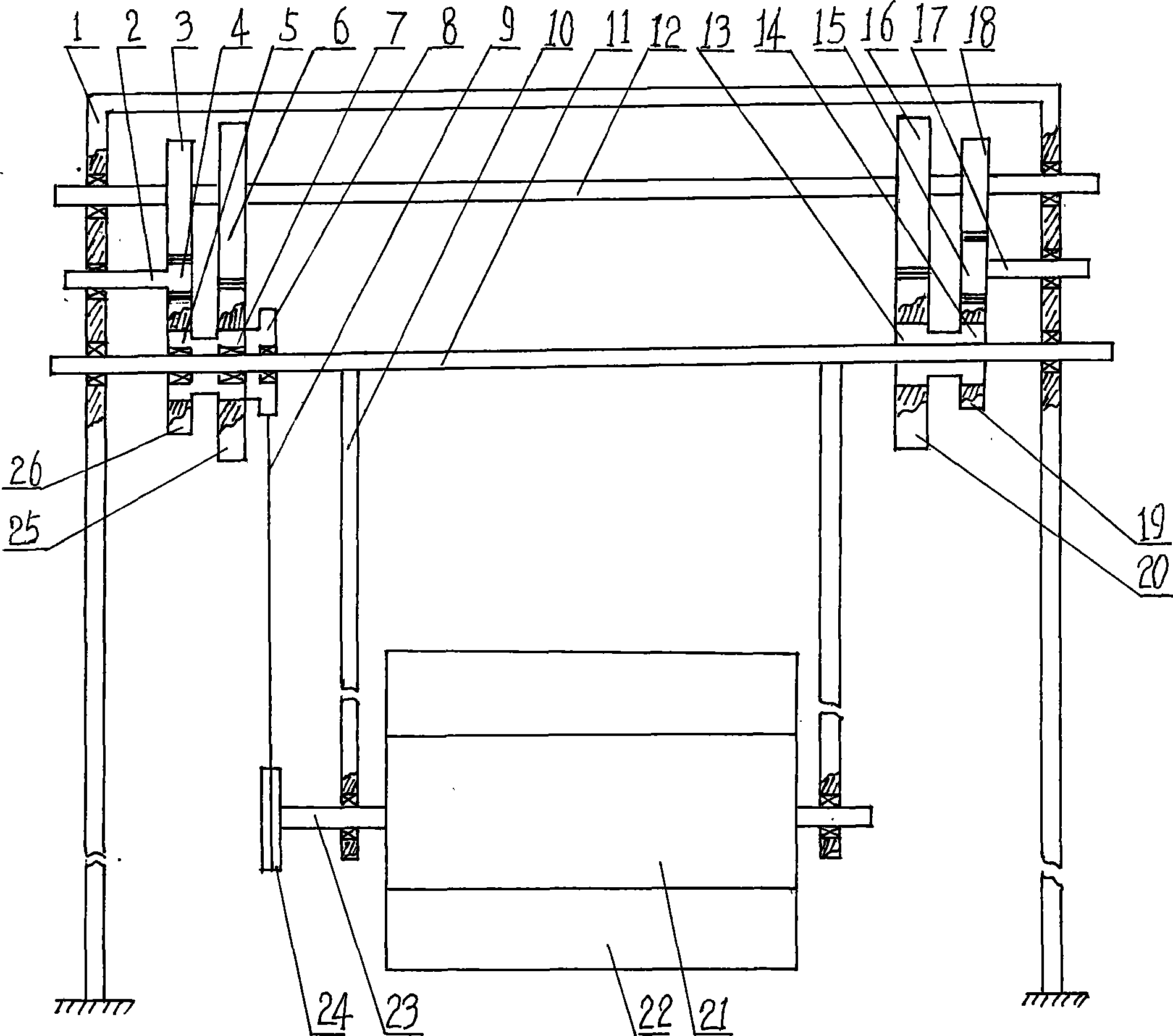

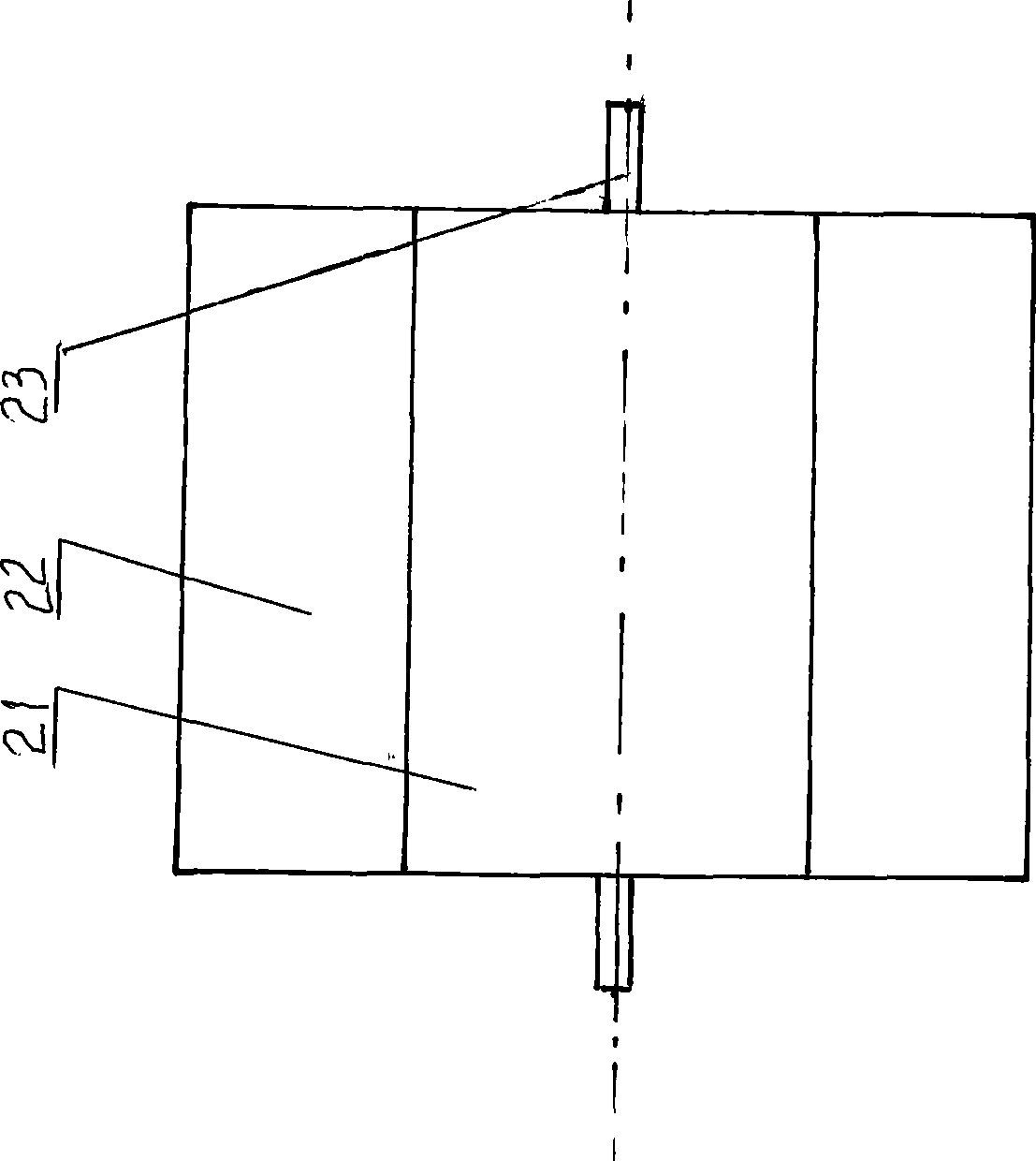

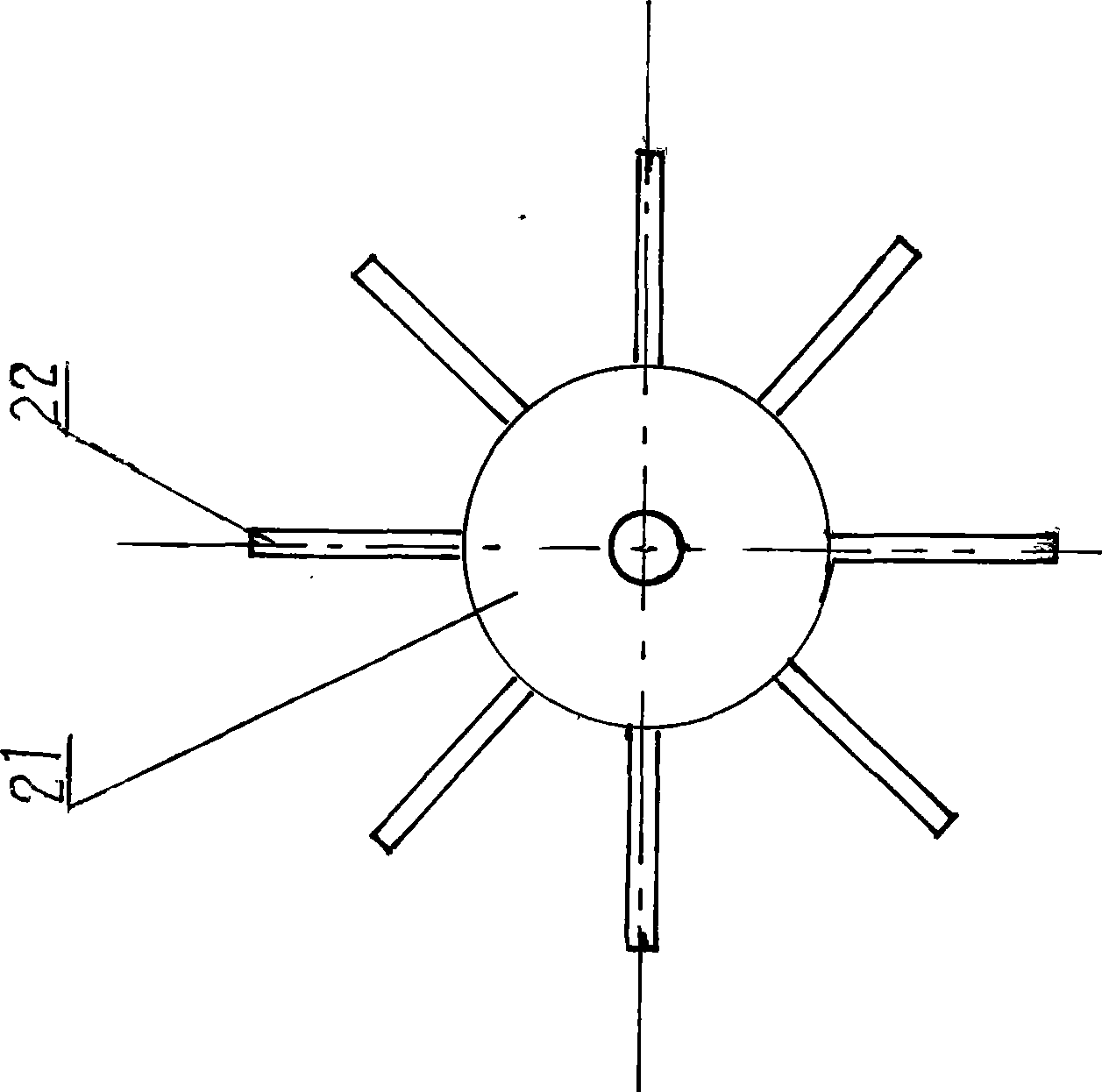

[0018] exist figure 1 , 2 , 3, the wave kinetic potential energy synchronous collection conversion device of the present embodiment is composed of support 1, kinetic energy reversing shaft 2, kinetic energy left driven gear 3, kinetic energy reversing gear 4, kinetic energy left ratchet 5, kinetic energy right driven gear 6, Kinetic energy right ratchet 7, driven sprocket 8, chain 9, swing lever 10, input shaft 11, output shaft 12, potential energy left ratchet 13, potential energy right ratchet 14, potential energy reversing gear 15, potential energy left driven gear 16, potential energy Reversing shaft 17, potential energy right driven gear 18, potential energy right driving gear 19, potential energy left driving gear 20, float 21, blade 22, float shaft 23, driving sprocket 24, kinetic energy right driving gear 25, kinetic energy left driving gear 26 Connection structure, wherein buoys 21, blades 22, and buoy shafts 23 are connected to form a kinetic energy collection wheel...

Embodiment 2

[0024] In this embodiment, the shape of the buoy 21 is cylindrical, and the outer surface of the cylinder of the buoy 21 is radially uniformly welded with two blades 22, and the angle between one blade 22 and the adjacent blade 22 is 180°. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0026] In this embodiment, the shape of the buoy 21 is cylindrical, and the outer surface of the cylinder of the buoy 21 is radially uniformly welded with 12 blades 22, and the angle between one blade 22 and the adjacent blade 22 is 30°. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0027] The working principle of the present invention is as follows:

[0028]During use, the lower end of the support 1 of the present invention is fixedly installed on the seabed, so that the buoy 21 floats on the sea surface. When the waves move forward or backward, the blades 22 are impulsed. Rotate clockwise or counterclockwise and move up and down, driving sprocket 24 drives driven sprocket 8 to rotate clockwise or counterclockwise through chain 9, kinetic energy right ratchet 7, kinetic energy left ratchet 5 rotate clockwise or counterclockwise. When the kinetic energy right ratchet 7 and the kinetic energy left ratchet 5 rotate clockwise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com