Screen detaching device for LCD

A liquid crystal display and machine technology, which is applied to instruments, optics, electrical components, etc., can solve the problems of unanalyzable electrical performance, low display efficiency, broken TFT substrate and color filter substrate, etc., to shorten the screen disassembly. Time, reduce labor intensity, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

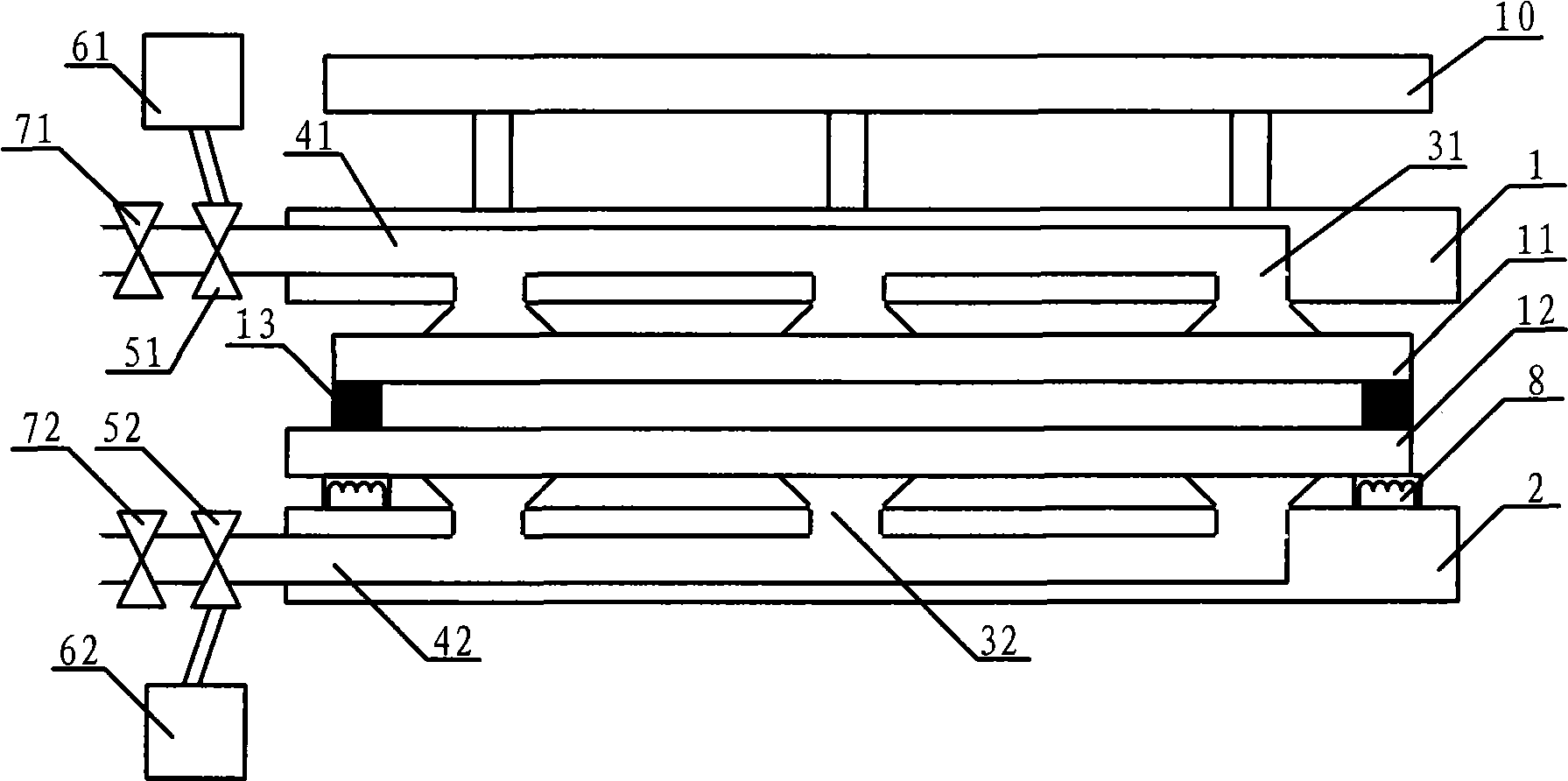

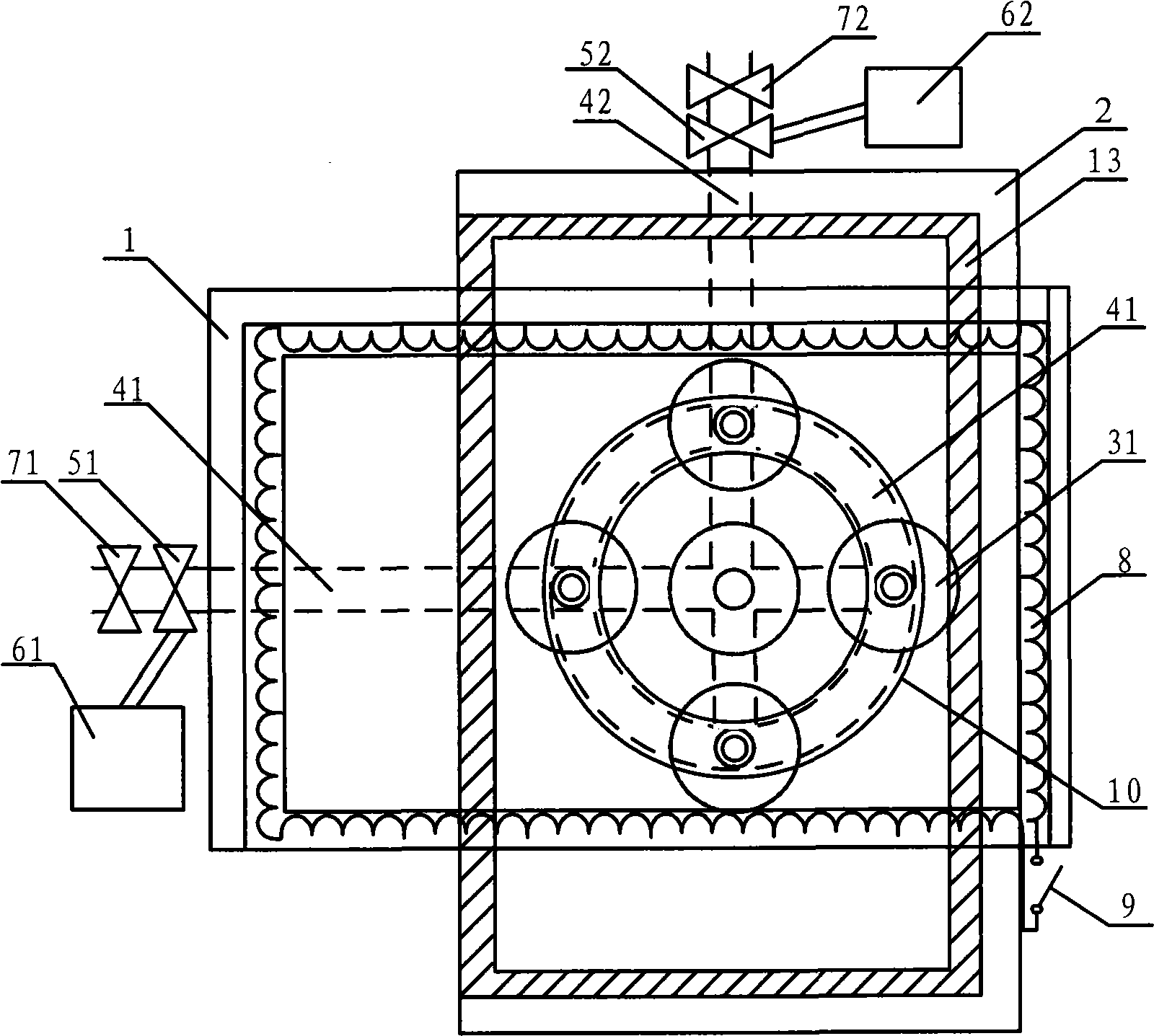

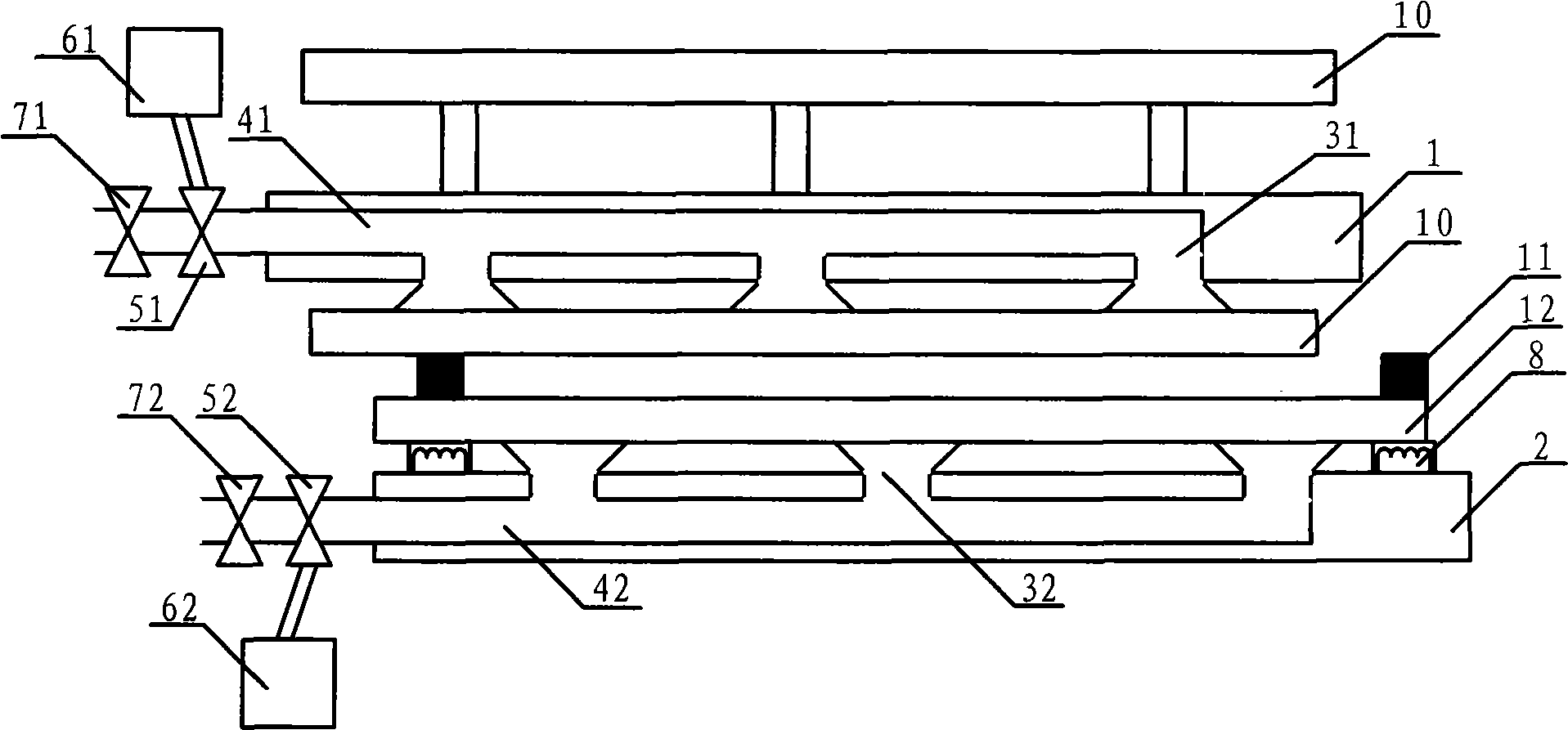

[0022] like figure 1 As shown, it is a schematic diagram of the structure of the LCD screen dismantling device of the present invention. This embodiment includes an upper machine table 1 and a lower machine table 2. The upper machine table 1 has an upper ventilation pipe 41, and the lower machine table 2 has a lower ventilation pipe 42; The upper suction cup 31 of the adsorption device is arranged on the upper ventilation pipe 41, and the lower suction cup 32 as the adsorption device is arranged on the lower ventilation pipe 42; 2 connected upper vacuum pump 61 and lower vacuum pump 62, and resistance wire 8 as a heating element.

[0023] In this embodiment, the upper machine table 1 and the lower machine table 2 are respectively provided with at least one suction cup. The upper suction cup 31 of the upper machine table 1 is used for suctioning the color filter substrate 11 of the liquid crystal display screen. The upper suction cup 31 is connected to the upper suction cup 31....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com