Permanent magnet rotating machine

A rotating machine and permanent magnet technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of increasing magnetic flux and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

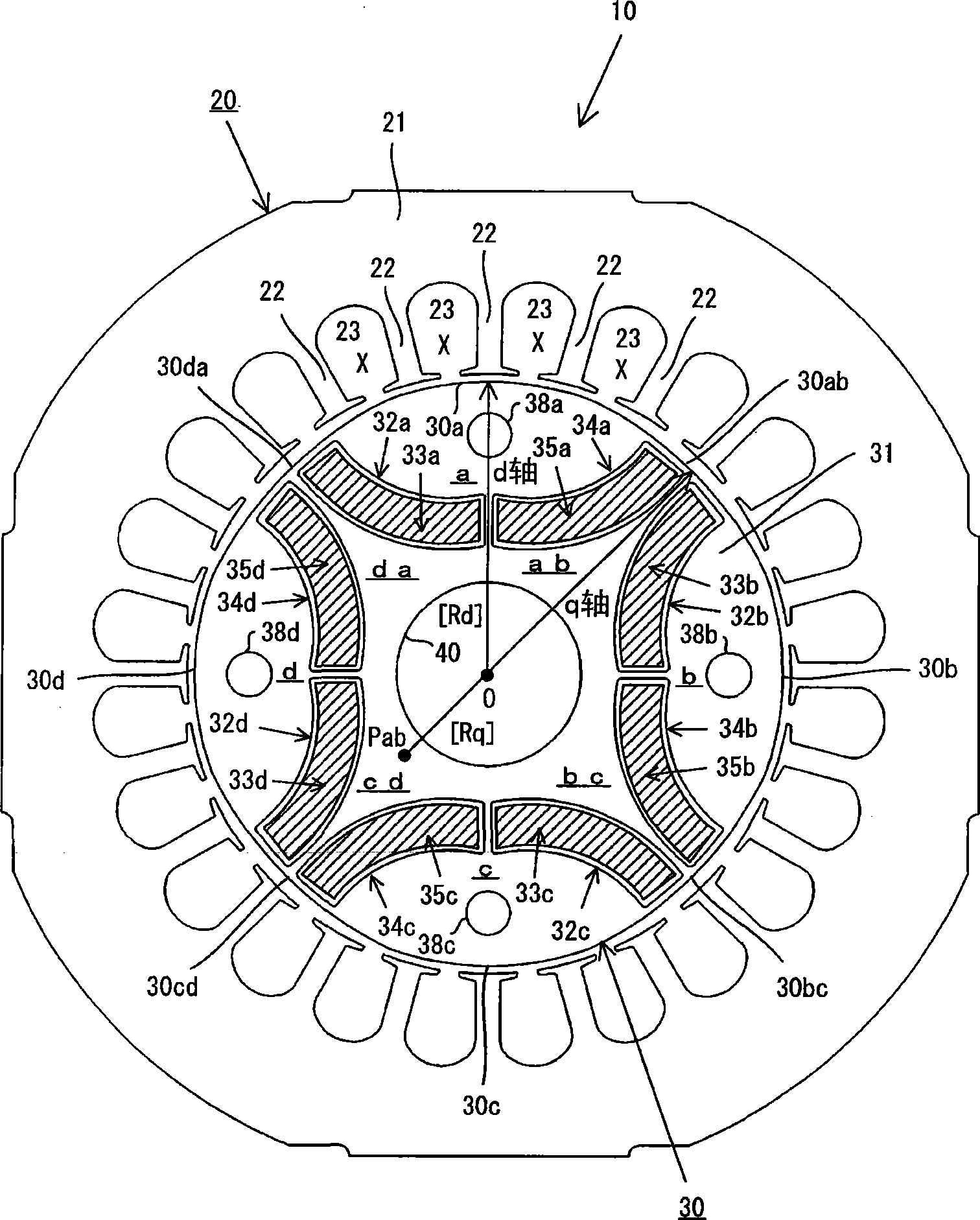

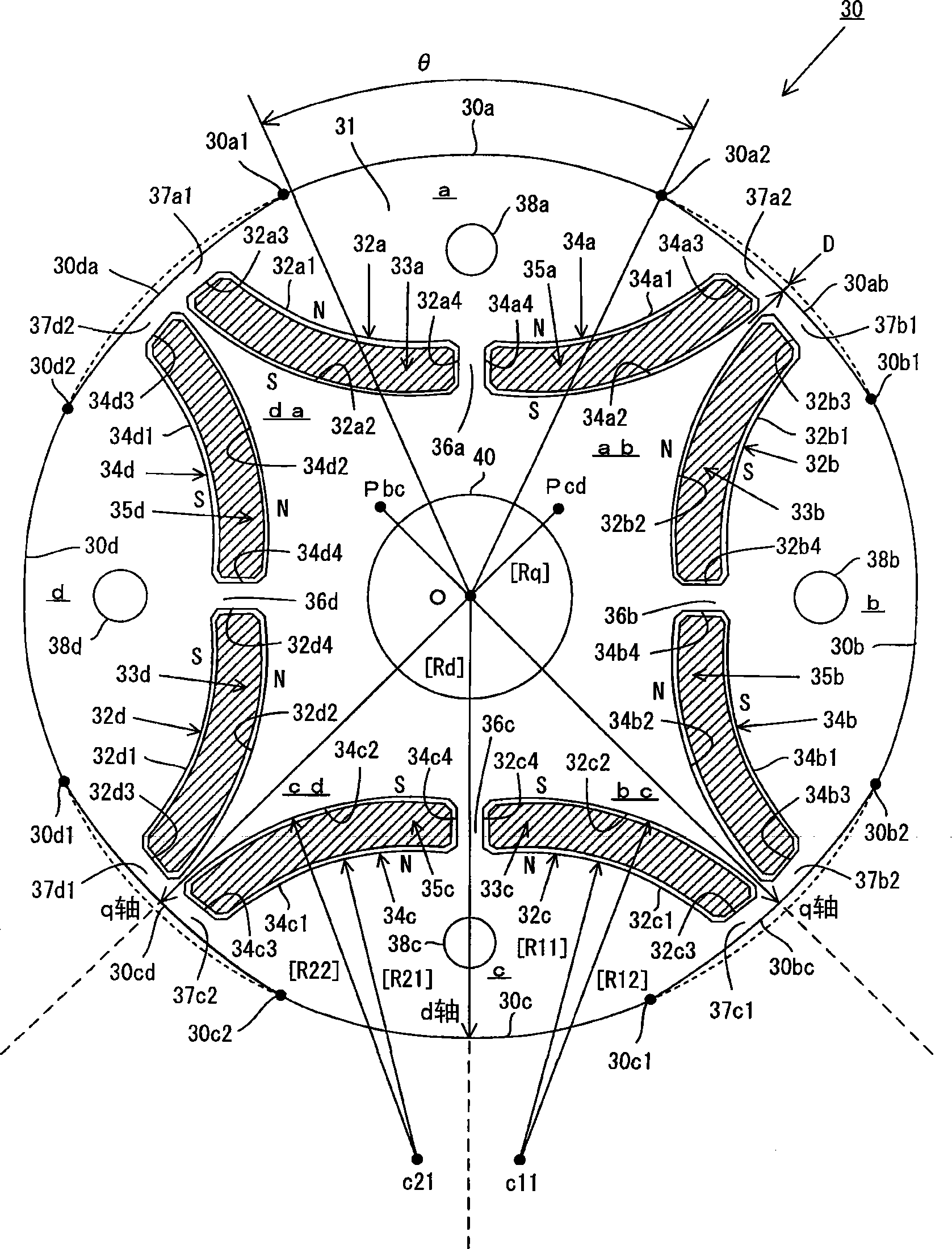

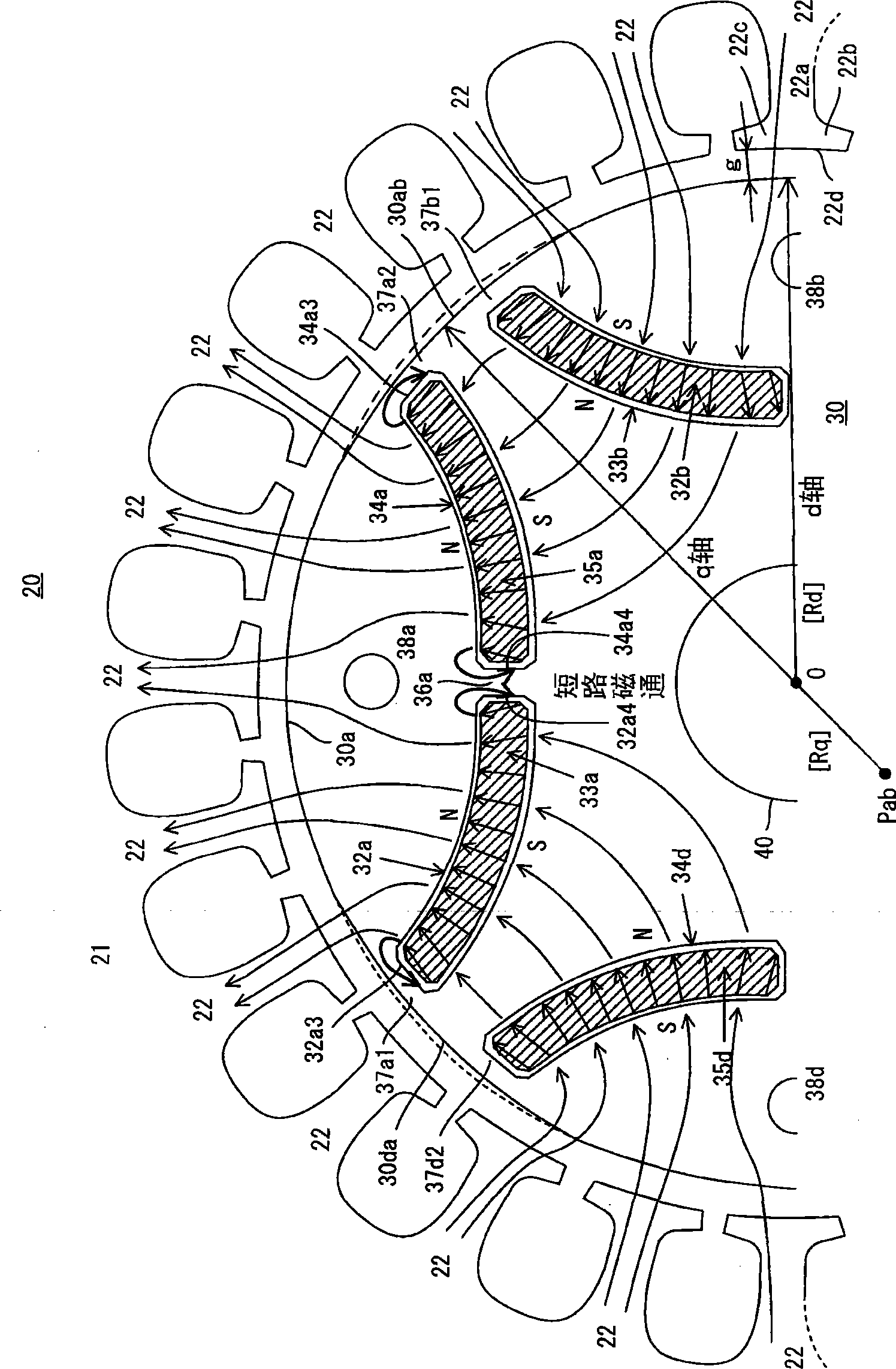

[0058] Conventionally, in permanent magnet motors, rare earth magnets (rare earth magnets) having a high magnetic flux density have been used. In particular, neodymium magnets containing Nd (neodymium), Fe (iron), Co (cobalt), B (boron) and the like are used. However, since rare earth magnets such as neodymium magnets are expensive, it is necessary to develop a permanent magnet motor using an inexpensive permanent magnet. Permanent magnet motors such as ferrite magnets.

[0059] In a permanent magnet motor in which permanent magnets are inserted into magnet insertion holes provided in the main magnetic pole portion of the rotor, the magnetic flux depends on the length of the outer wall (wall on the outer peripheral surface) of the magnet insertion hole. Therefore, when using a magnet with a low magnetic flux density such as a ferrite magnet, compared with the case of using a rare-earth magnet with a high magnetic flux density, in order to obtain a permanent magnet motor with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com