Thermoplastic resin composition and molded article

A thermoplastic resin and composition technology, applied in the superstructure sub-assembly, passenger space, steering control installed on the car, etc., can solve the problems of deformation of molded products, reduced mechanical strength, insufficient heat resistance, etc. Excellent balance of heat resistance and impact resistance, excellent chemical resistance and heat resistance, and excellent heat resistance and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14 and comparative example 1~4

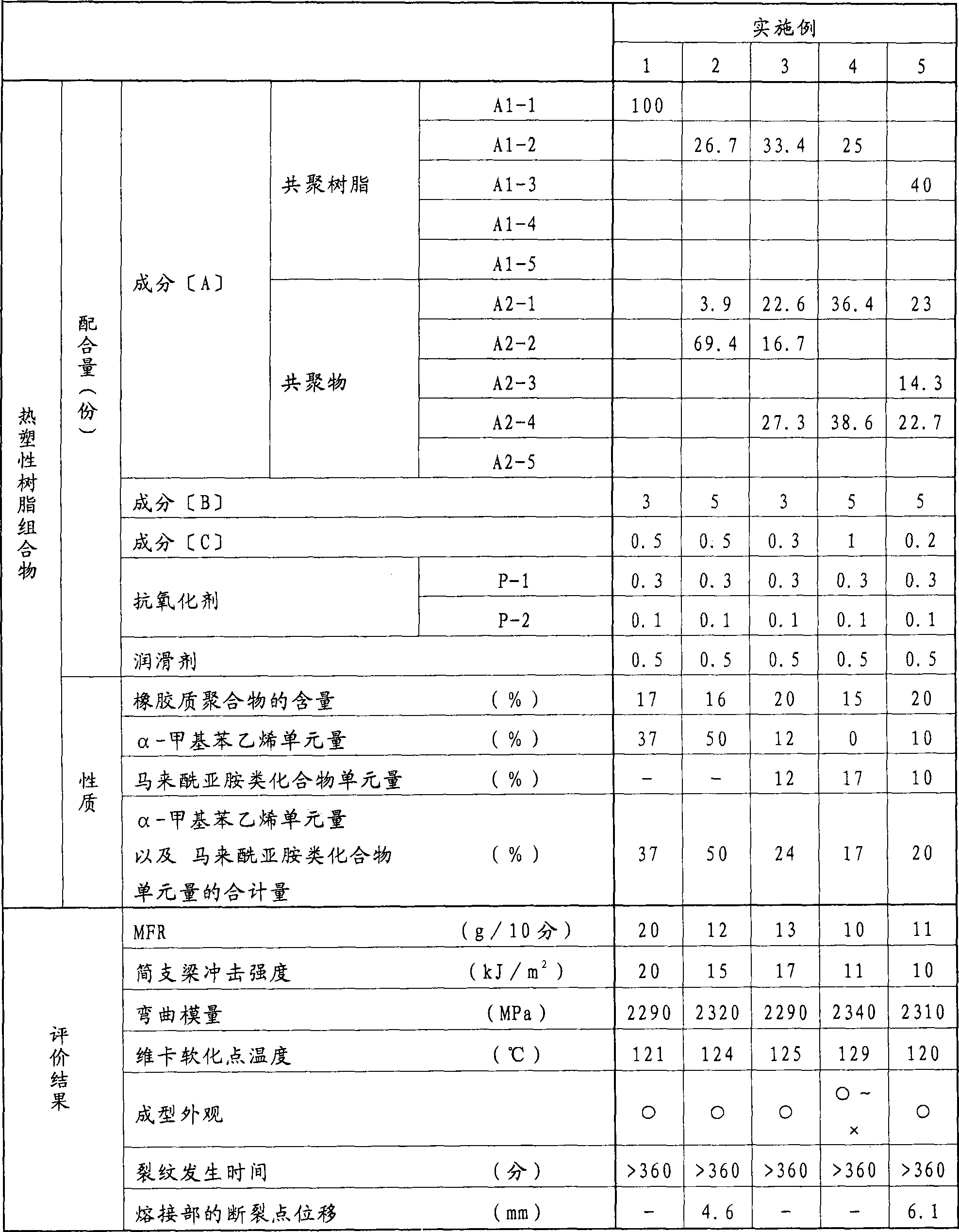

[0372] Using the above-mentioned components [A] to [C], an antioxidant, and a lubricant, granules (thermoplastic resin composition) were used, and various evaluations were performed. The results are listed in Tables 1 to 4 together.

[0373] 【0102】

[0374] 【Table 1】

[0375] Table 1

[0376]

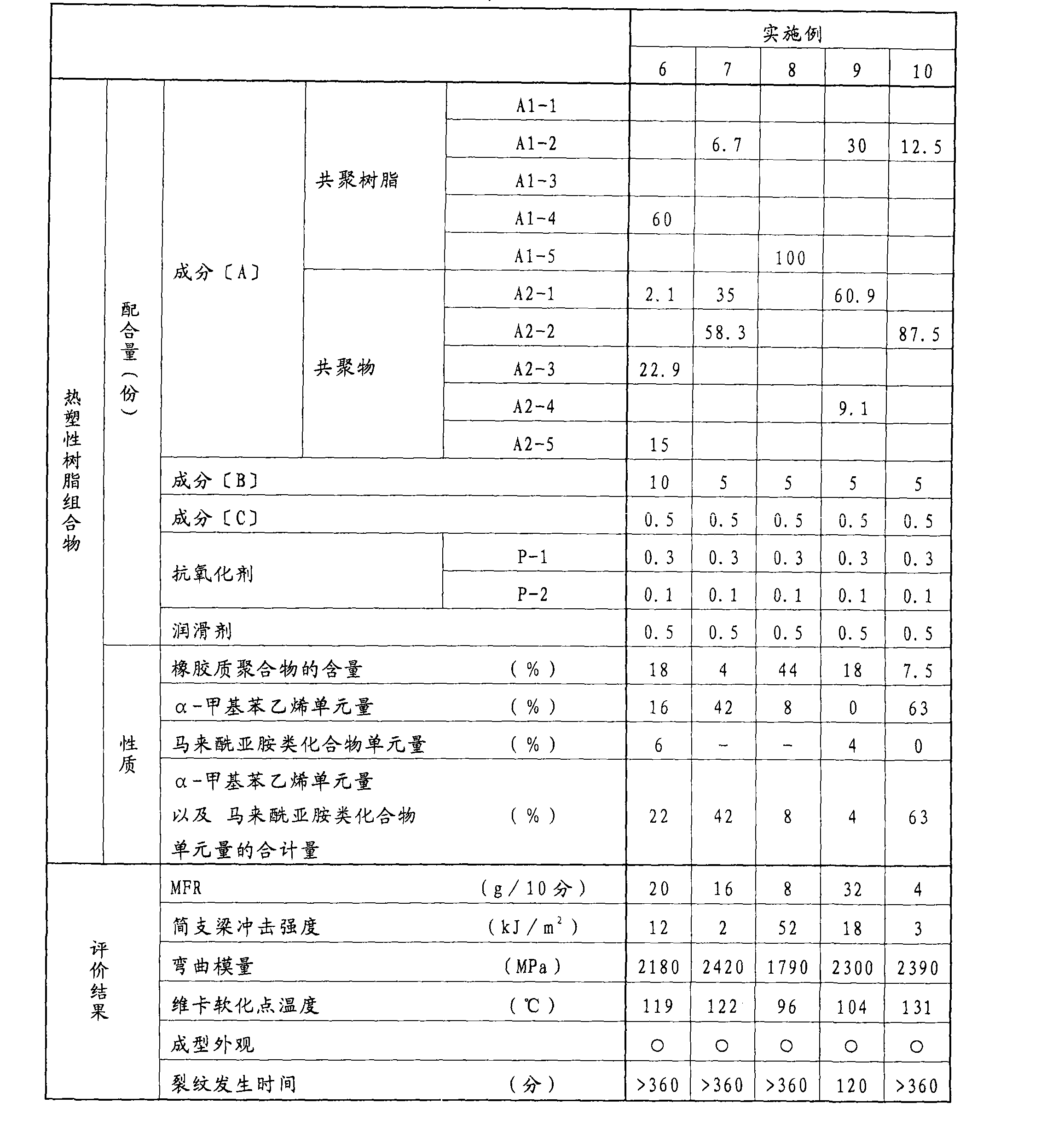

[0377] 【0103】

[0378] 【Table 2】

[0379] Table 2

[0380]

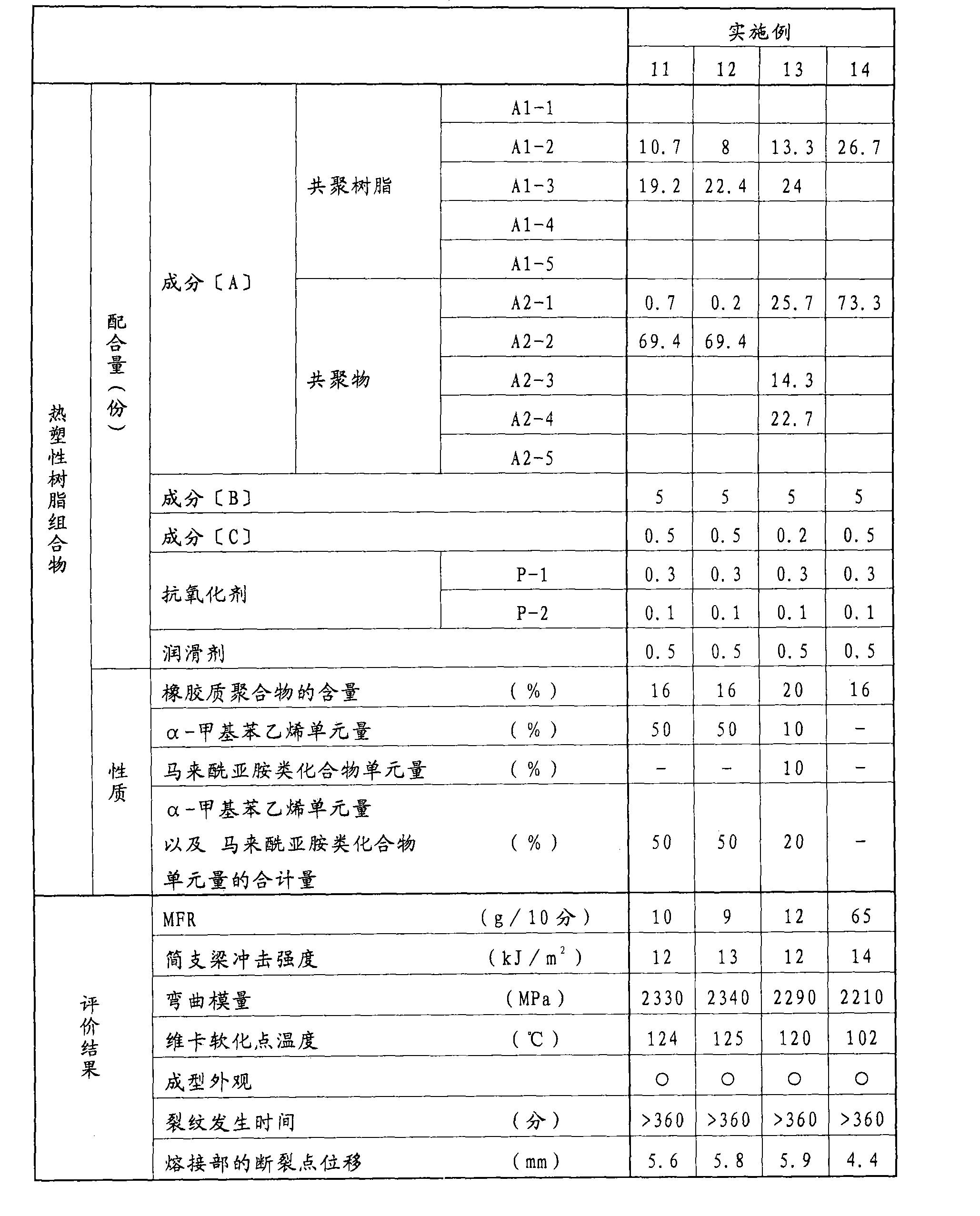

[0381] 【0104】

[0382] 【table 3】

[0383] table 3

[0384]

[0385] 【0105】

[0386] 【Table 4】

[0387] Table 4

[0388]

[0389] 【0106】

[0390] From Tables 1 to 4, the following results can be seen.

Embodiment 15~24 and comparative example 5~8

[0396] The above components [A] to [C], modified olefin resin, antioxidant and lubricant were used to granulate (thermoplastic resin composition), and various evaluations were performed. The results are listed in Tables 5 to 7 together.

[0397] 【0108】

[0398] 【table 5】

[0399] table 5

[0400]

[0401] 【0109】

[0402] 【Table 6】

[0403] Table 6

[0404]

[0405] 【0110】

[0406] 【Table 7】

[0407] Table 7

[0408]

[0409] 【0111】

[0410] From Tables 5 to 7, the following results can be seen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com