Process for production of black crayon

A manufacturing method and technology of crayons, applied in the direction of pencil lead, non-active pencil, printing, etc., can solve the problems of poor gelation, inability to manufacture crayons stably, short heating time, etc., and achieve the effect of stable manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

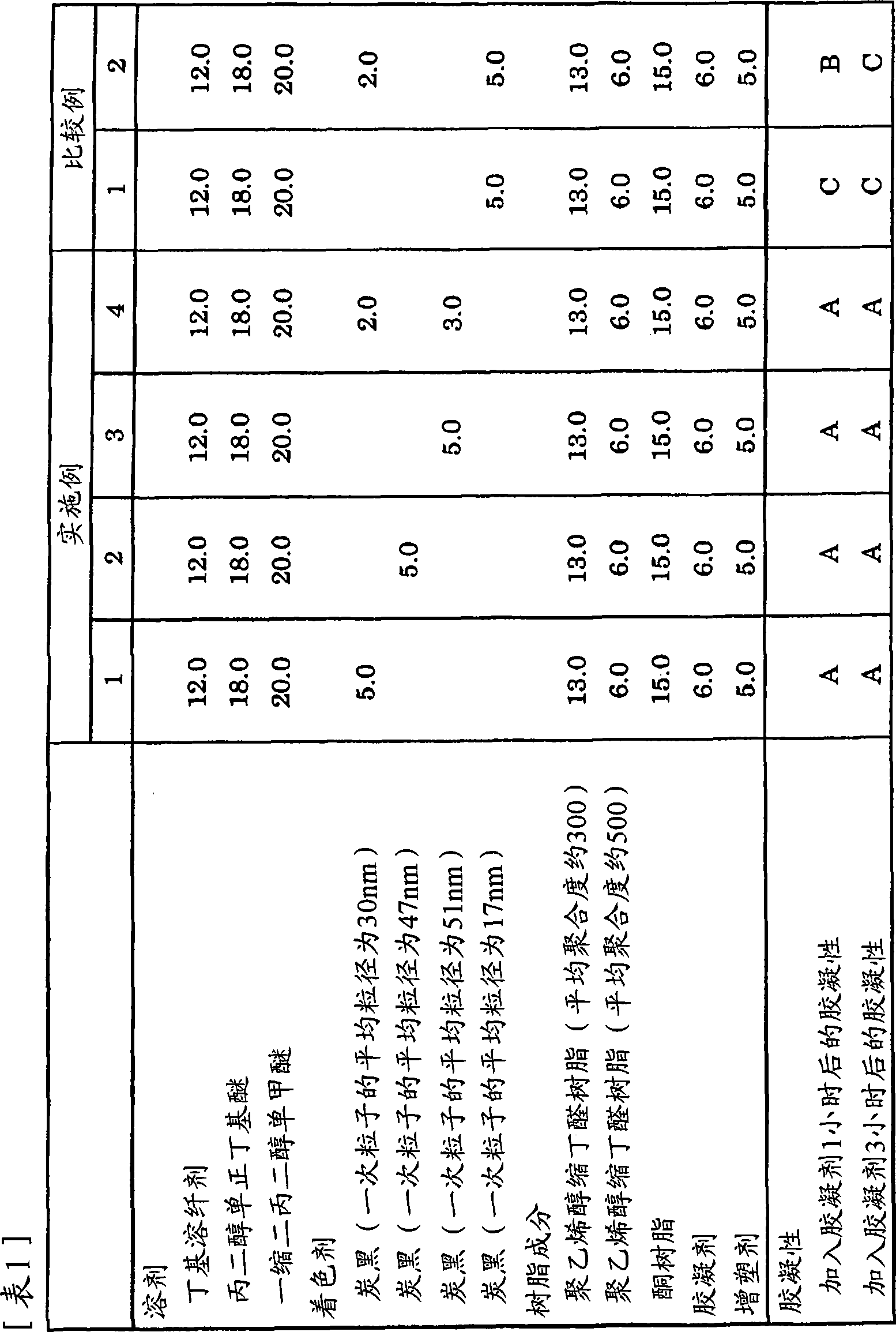

[0030] A mixed solvent comprising 12.0 parts by weight of ethylene glycol monobutyl ether, 18.0 parts by weight of propylene glycol n-butyl ether and 20.0 parts by weight of dipropylene glycol monomethyl ether was heated to 30°C, and 5.0 parts by weight of phthalic acid was dissolved therein Dibutyl ester, and further, 13.0 parts by weight of polyvinyl butyral resin (MOWITAL B-20H manufactured by Kuraray, the average degree of polymerization is about 300) and 6.0 parts by weight of polyvinyl butyral resin (Kurare MOWITAL B-30H, the average degree of polymerization is about 500) dissolved.

[0031] Then, while heating the resin solution obtained as described above to 30° C., 5.0 parts by weight of carbon black (#30 manufactured by Mitsubishi Chemical Co., Ltd.) having an average particle diameter of primary particles of 30 nm was added thereto and dispersed, While heating to 130°C, 15.0 parts by weight of a ketone resin ("HIRA" manufactured by Hitachi Chemical Co., Ltd.) was ad...

Embodiment 2~4

[0034] Except having used the component shown in Table 1 in the amount shown in Table 1, it carried out similarly to Example 1, and obtained the crayon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com