Superfine type fine-powder ball mill

A ball mill and fine powder technology, applied in the ultra-fine fine powder ball mill, high-speed field, can solve the problems of easy heating, grinding, low filtration efficiency, etc., to achieve the effect of not easy to heat, avoid agglomeration into agglomerates, and large filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

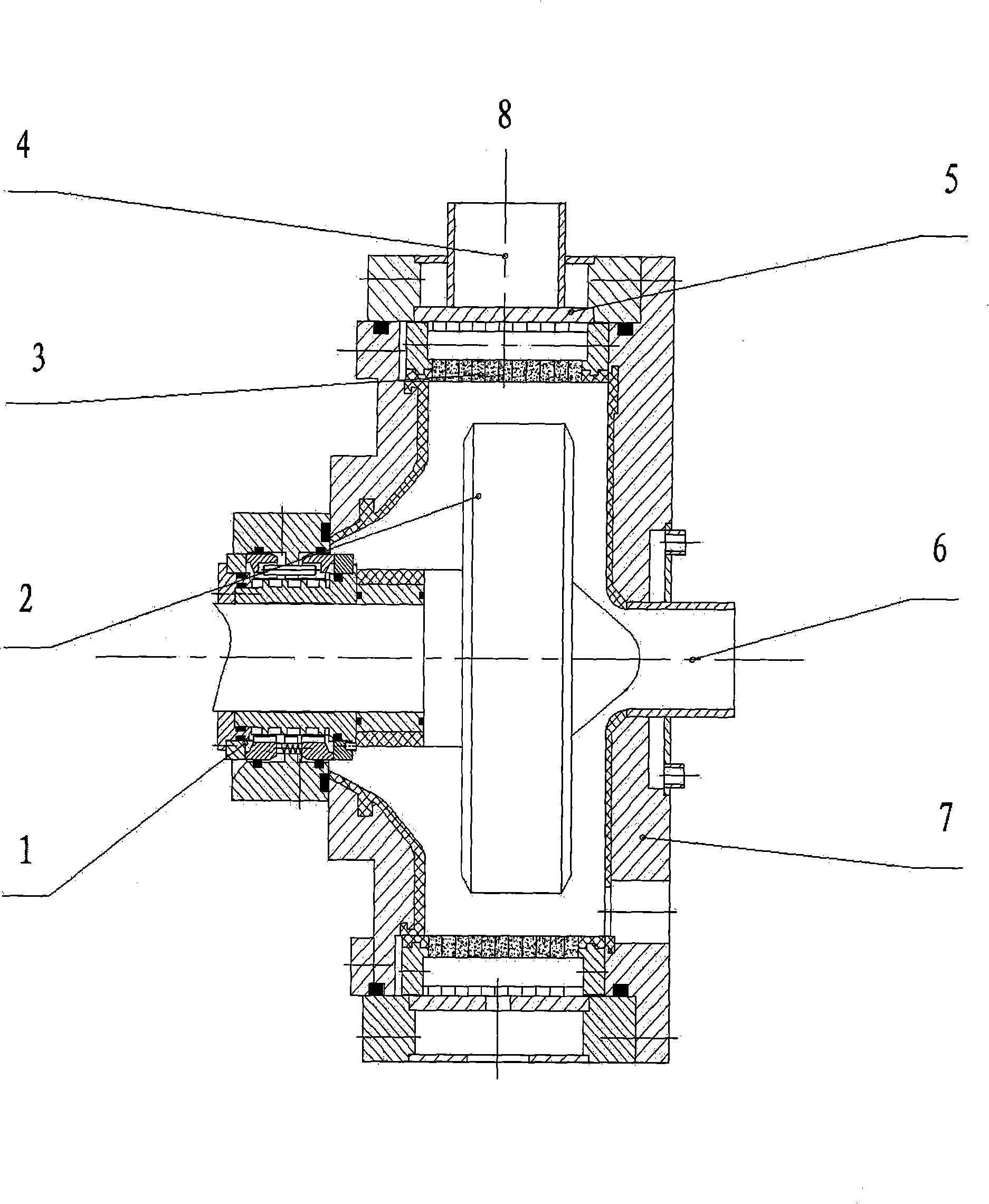

[0009] The ultra-fine powder ball mill of the present invention includes a cylinder body and a power mechanism. The cylinder body (2) is disc-shaped and cylindrical, and the ratio of its axial length to its diameter is less than one-half. There are grinding impellers (5) and several grinding steel balls (4), and the two axial side walls are respectively processed with a center hole and a feed inlet (6). The end of the output shaft (8) of the power mechanism is supported by bearings and The sealing ring is fixed in the central shaft hole of the grinding impeller (5) after being sealed and movable and penetrating the central hole. An annular cavity for forming an annular jacket (7) is processed on the circumferential side wall of the cylinder body (2), and a cooling water inlet and outlet are processed on the circumferential side wall of the cylinder body (2). It is connected with the annular jacket, and then through the external water pump and water pipe, the cooling water can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com