Pyrolysis furnace COT thermocouple anti-degrading and anti-coking sleeve pipe

An anti-scouring and thermocouple technology, applied in the direction of thermometers, measuring heat, and using electrical devices that are directly sensitive to heat, electric/magnetic components, etc., can solve problems such as inability to guarantee fluid media, easily damaged instruments, and leaking connections. , to achieve good temperature measurement sensitivity and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

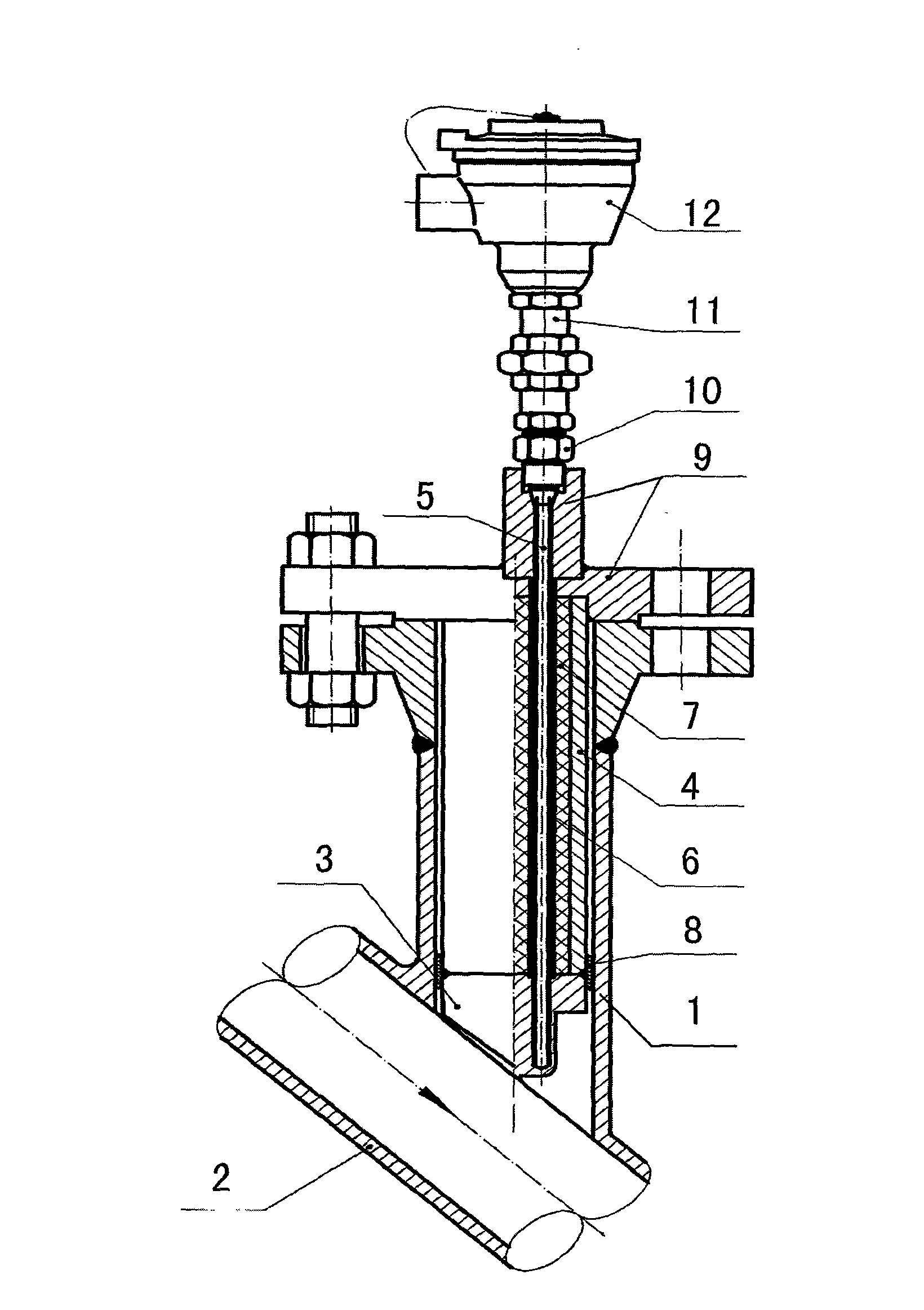

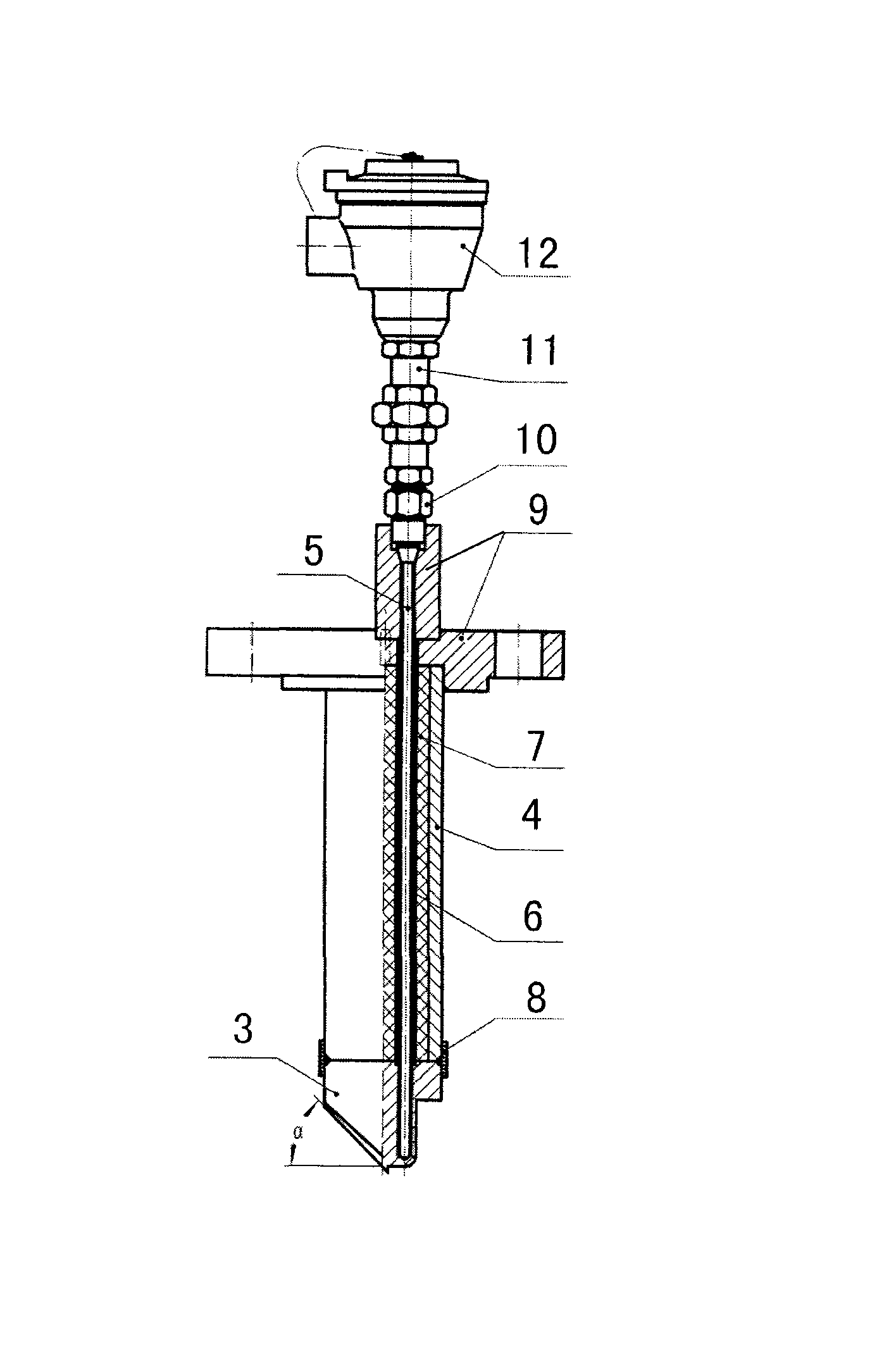

[0030] The structure of the present invention will be further described below in conjunction with the accompanying drawings of the description:

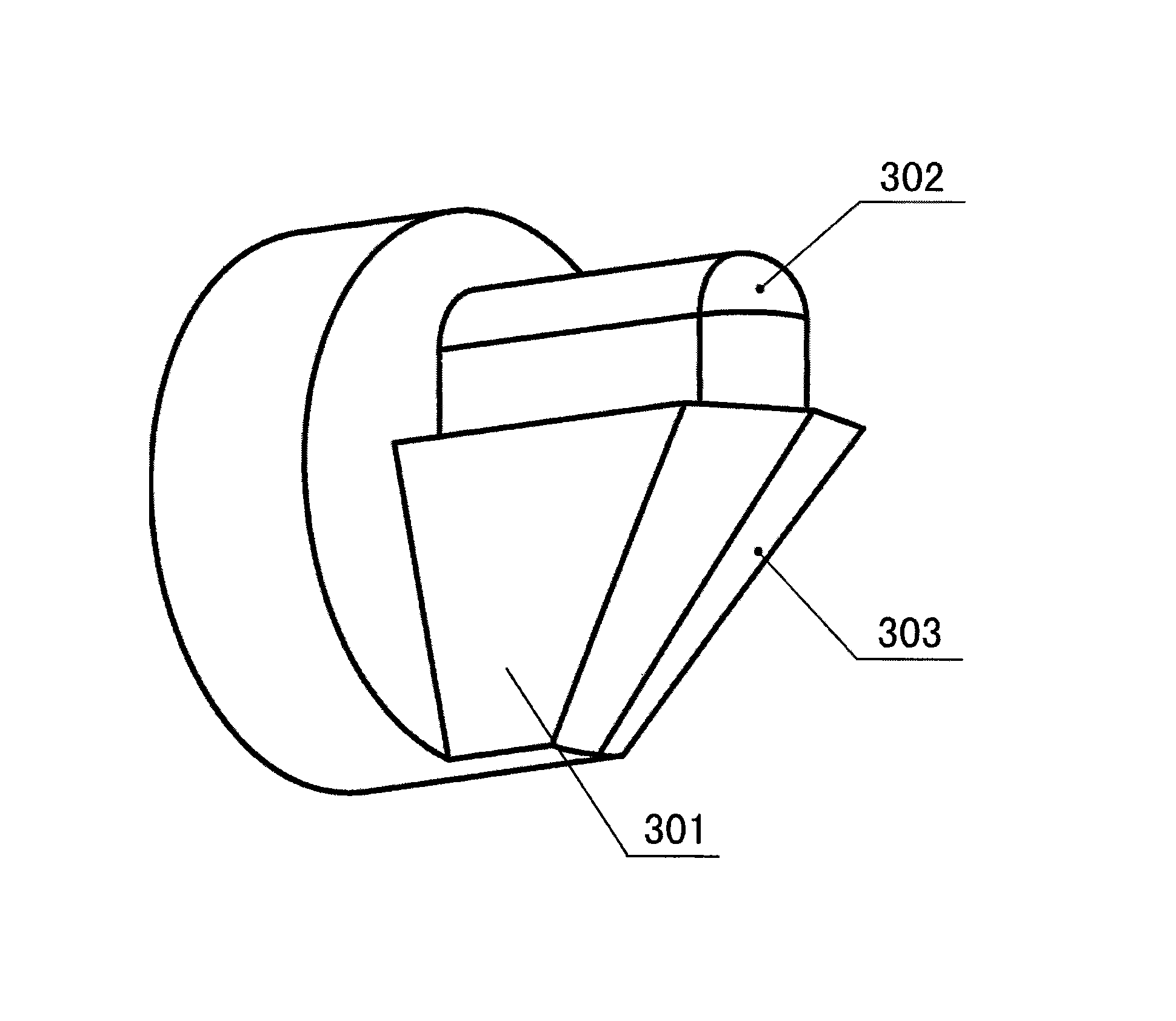

[0031] A kind of pyrolysis furnace COT thermocouple anti-scouring anti-coking casing 1 proposed by the present invention (see figure 1 , figure 2 ), comprising a measuring end 3, a lower protective tube 4, a thermocouple 5 (preferably, an armored thermocouple is used in an embodiment of the present invention), an upper protective tube 11 and a junction box 12, the temperature measuring end 3 and the lower end of the lower protective tube 4 Seal welding, the upper end of the lower protection tube 4 is fixedly connected with the process connection flange 9; the cracking furnace COT thermocouple anti-scouring and anti-coking casing passes the process connection flange 9 to fix the lower protection tube 4 in the equipment connection tube 1; the measuring end 3 An anti-scouring body 301 and a temperature measuring head 302 are provided,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com