Back irradiation plane type PIN structure GaN-based ultraviolet detector and preparation method

A UV detector, planar technology, applied in the field of UV detectors, to achieve the effects of avoiding large surface recombination, improving reliability and practicability, and facilitating interconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] According to the half-height width of the required response peak, the material and structure of the back-illuminated planar PIN-based GaN ultraviolet photodetector are designed in combination with the theoretical and practical technical level and material parameters. The detailed process will be described in combination with our examples.

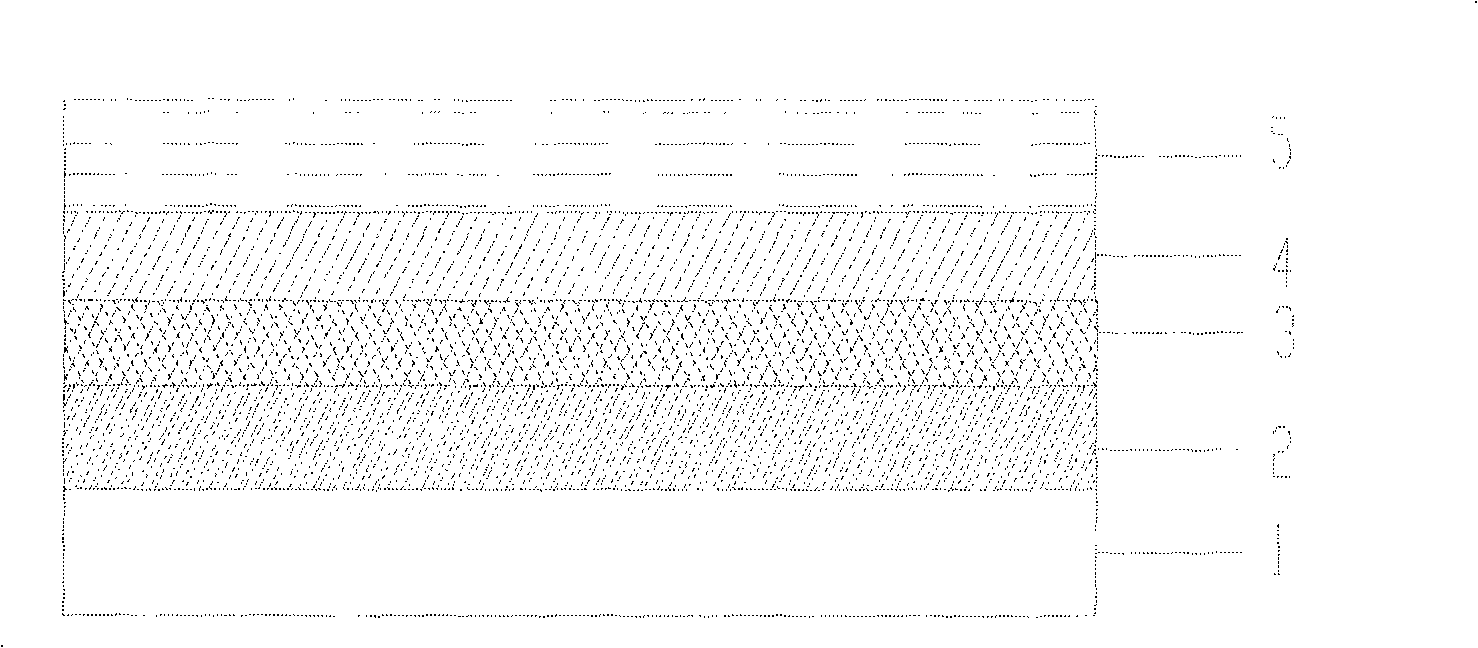

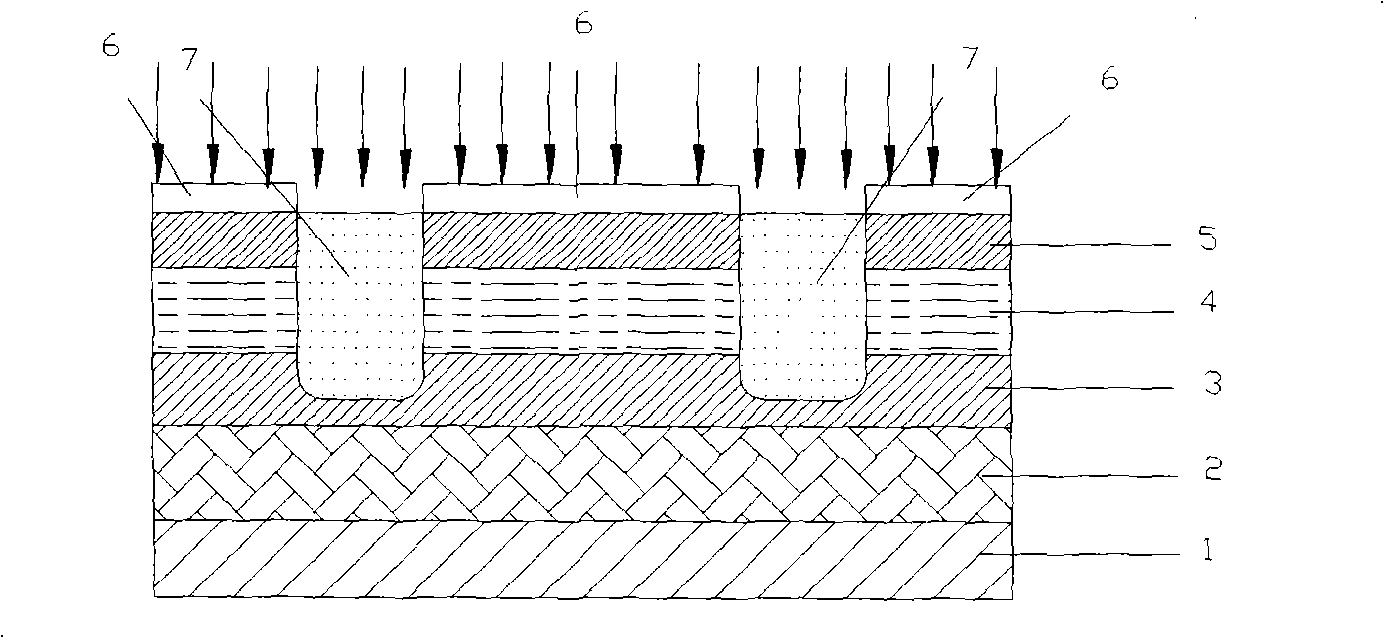

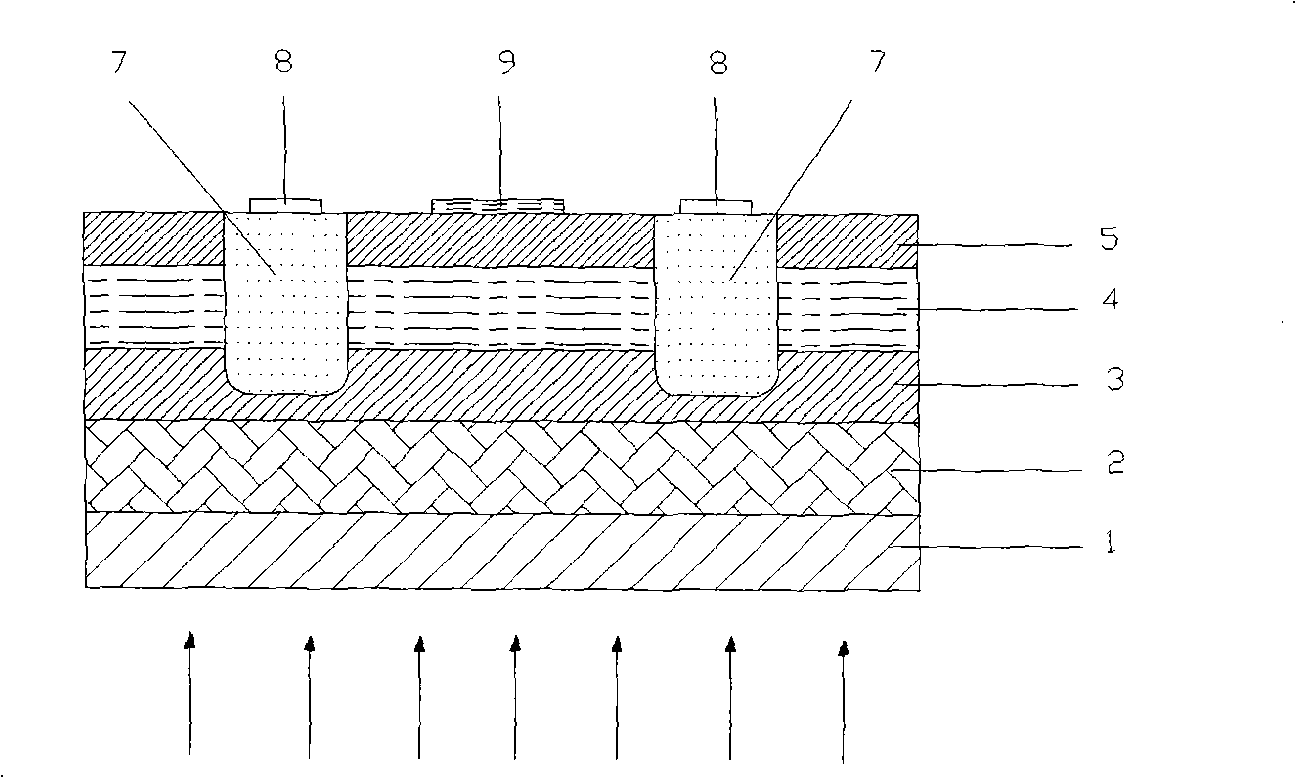

[0030] The structure of the back-illuminated planar PIN structure GaN-based ultraviolet detector as shown in the accompanying drawing of the figure description is to epitaxially grow a layer of about 0.6 micron thick undoped Doped AlN buffer layer 2; about 1 micron thick Si doping concentration is 1×10 18 cm -3 n-type Al 0.3 Ga 0.7 N layer 3; active layer 4 is an intrinsic GaN layer with a thickness of about 0.15 microns and an electron concentration of 2×10 16 cm -3 ; Finally, a Mg-doped p-GaN layer 5 with a thickness of about 0.1 micron, with a hole concentration of about 2×10 17 cm -3 . Use a high-energy ion implanter to i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electron concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com