Digital microfluid micro-mixer and mixing method

A technology of digital microfluidics and micromixers, which is applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of space flexibility of digital microfluidics that limit the degree of integration, and improve the flexibility of space manipulation and integration degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

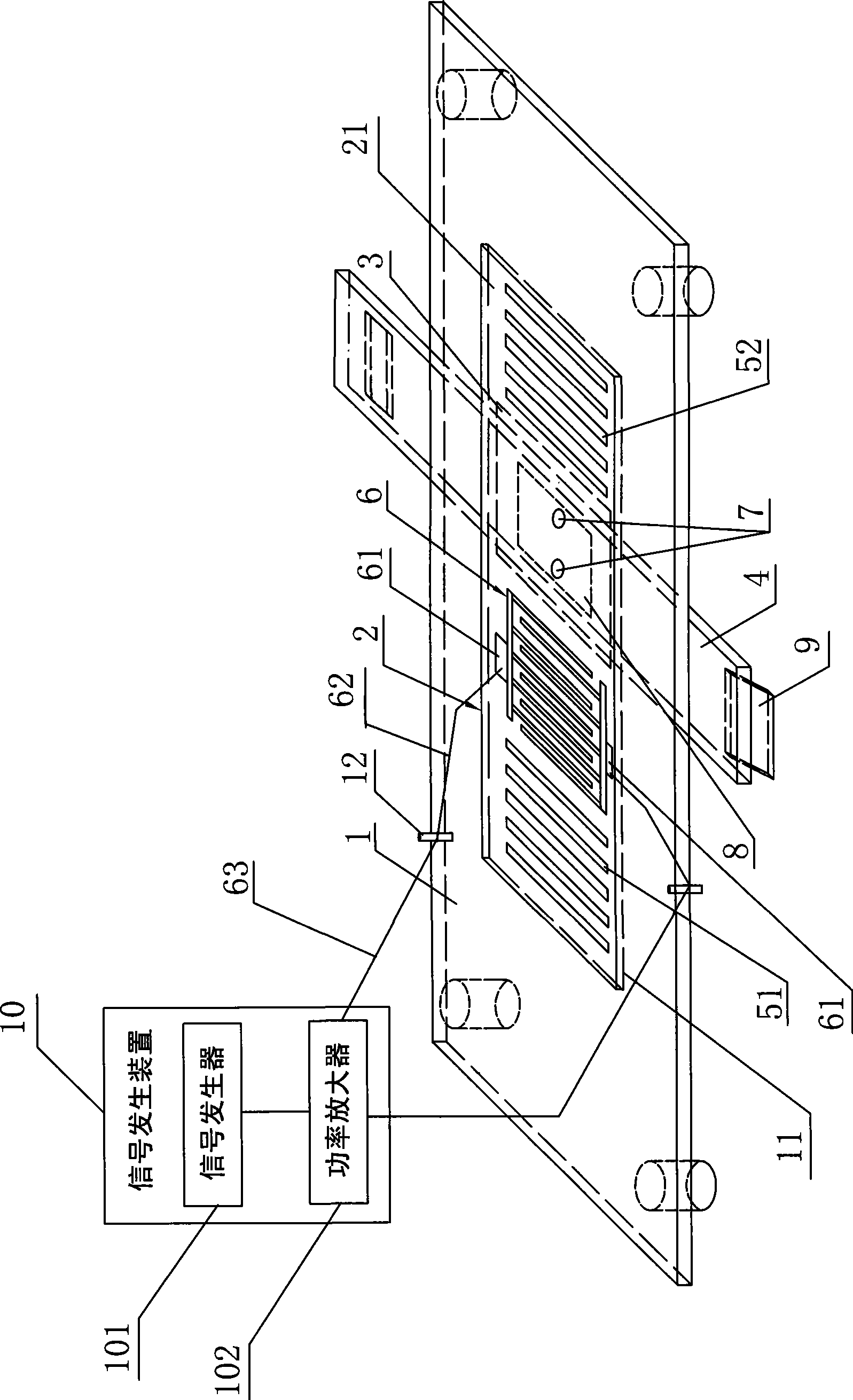

[0026]As shown in the figure, a digital microfluidic micro-mixer includes a stage 1 made of a PCB (Printed Circuie Board, printed circuit board), a piezoelectric substrate 2, a glass slide 4 and a The movable support 9 of the glass slide 4 is provided with a cavity 11 on the stage 1, and the piezoelectric substrate 2 is arranged in the cavity 11. The lower surface of the piezoelectric substrate 2 is the working surface 21. In the actual application process , the periphery of the piezoelectric substrate 2 can be directly bonded to the inner wall of the cavity 11 through any existing adhesive, or the piezoelectric substrate 2 can be arranged in the cavity 11 in other ways. The working surface 21 is provided with a first reflective grid 51, a second reflective grid 52, an interdigital transducer 6 and a first hydrophobic layer 3 for two digital m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com