PVC resin composition and product thereof

A technology of PVC resin and composition, applied in the field of PVC resin composition, can solve the problems such as the decline of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

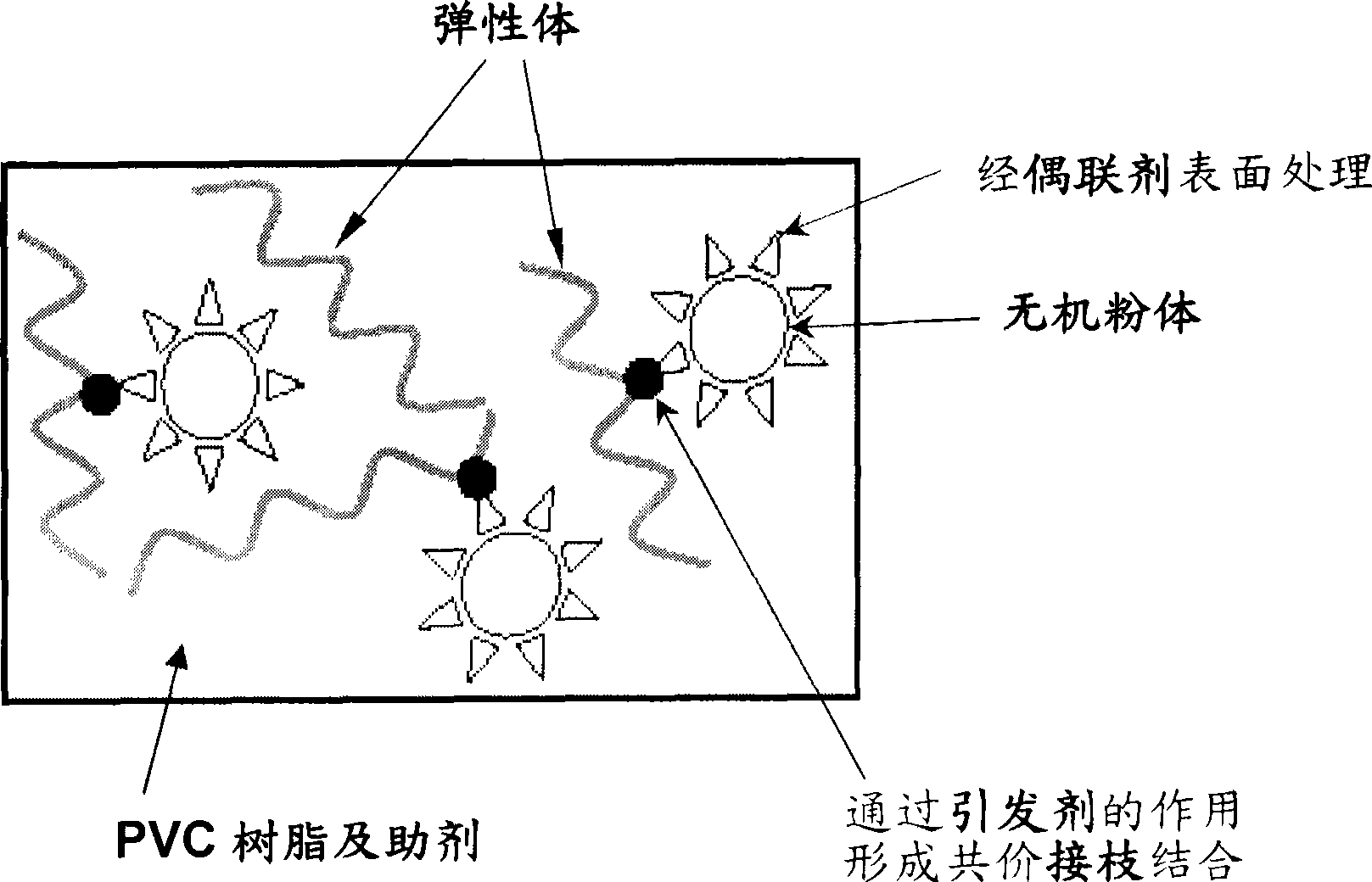

Method used

Image

Examples

Embodiment 1

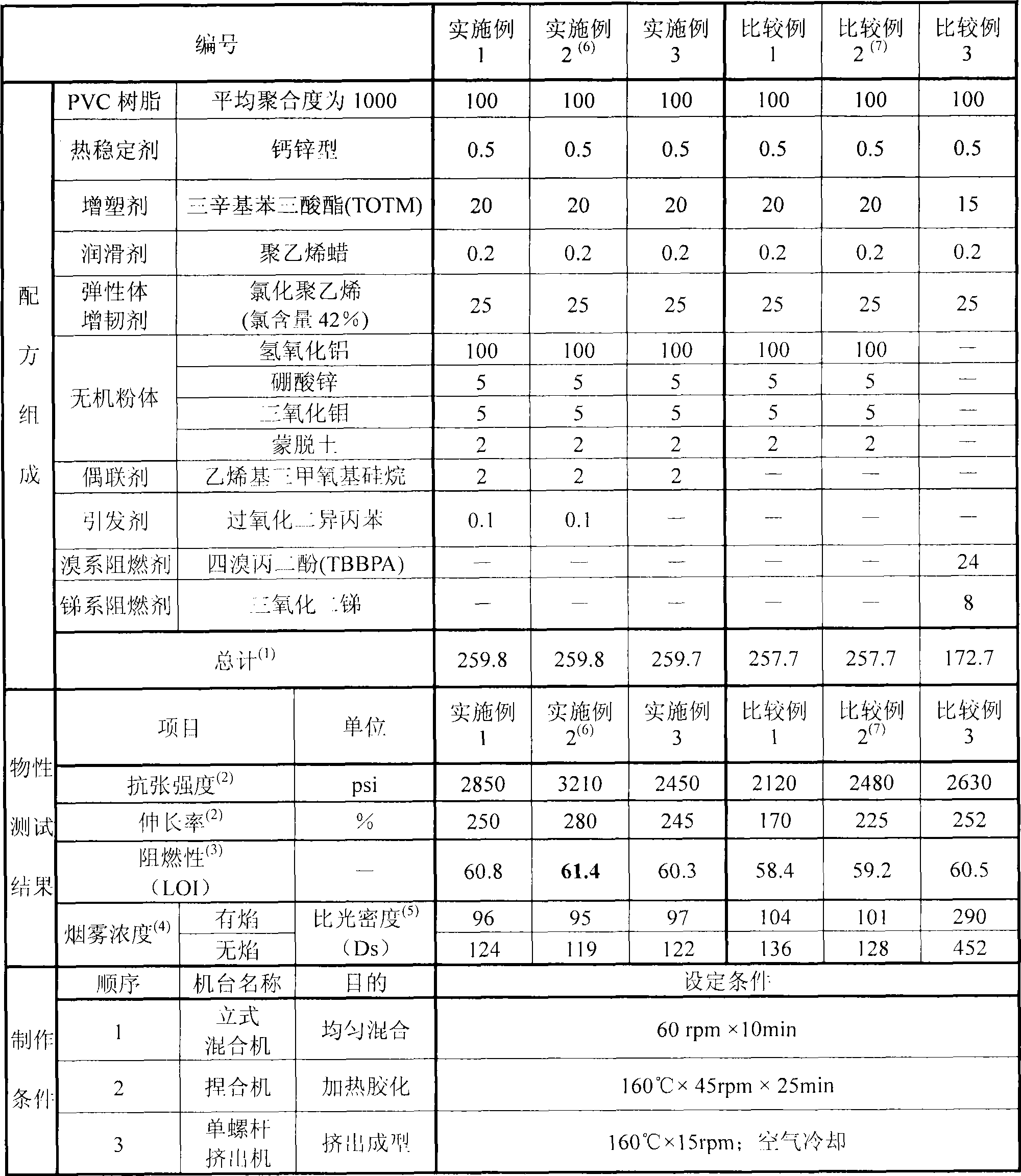

[0037] The PVC resin (average degree of polymerization 1000) of 100 parts by weight, the calcium-zinc type stabilizer of 0.5 parts by weight, the trioctyl trimellitate (TOTM) plasticizer of 20 parts by weight, the polyethylene wax lubrication of 0.2 parts by weight agent, 25 parts by weight of chlorinated polyethylene elastomer toughening agent, an appropriate amount of inorganic powder (including 100 parts by weight of aluminum hydroxide, 5 parts by weight of zinc borate, 5 parts by weight of molybdenum trioxide and 2 parts by weight of Montmorillonite), 2 weight parts of vinyltrimethoxysilane coupling agent, 0.1 weight part of dicumyl peroxide initiator, put into vertical mixer together and carry out stirring and mixing at room temperature under the condition of 60rpm * 10min, After mixing, put it into the kneader for gelation under the condition of tank temperature 160℃×45rpm×25min. After the gelation is completed, take out the gelled material from the kneader, and then send...

Embodiment 2

[0040] PVC resin composition is the same as embodiment 1, but the chlorinated polyethylene elastomer toughening agent of 25 parts by weight in the composition of embodiment 1, inorganic powder (comprising the aluminum hydroxide of 100 parts by weight, the zinc borate of 5 parts by weight, 5 parts by weight The molybdenum trioxide of weight part and the montmorillonite of 2 weight parts), the vinyltrimethoxysilane coupling agent of 2 weight parts, the dicumyl peroxide initiator of 0.1 weight part, then carry out mixing, gelatinization in advance , and make masterbatches according to the production conditions in Table 1.

[0041] The prepared masterbatch is dropped into the PVC resin (average degree of polymerization 1000) of 100 weight parts in proportion, the calcium-zinc type stabilizer of 0.5 weight part, the trioctyl trimellitate (TOTM) plasticizing of 20 weight parts Agent and 0.2 parts by weight of polyethylene wax lubricant, then through mixing, gelation and according to...

Embodiment 3

[0044] Except not adding dicumyl peroxide initiator, PVC resin composition and preparation conditions are the same as embodiment 1.

[0045] The properties of the obtained PVC resin composition were measured, and the results are shown in Table 1 in detail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com