Preparation of alpha-cyanacrylate adhesive

A cyanoacrylate and adhesive technology, used in the preparation of organic compounds, the preparation of carboxylic acid nitrile, and non-polymer organic compound adhesives, etc., can solve the problem of whitening of α-cyanoacrylate adhesives. It solves the problems of irritation, affecting the aesthetics of the surface of items, and prone to frosting and whitening, so as to achieve the effect of simple and easy preparation method, improved product performance and reduced irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

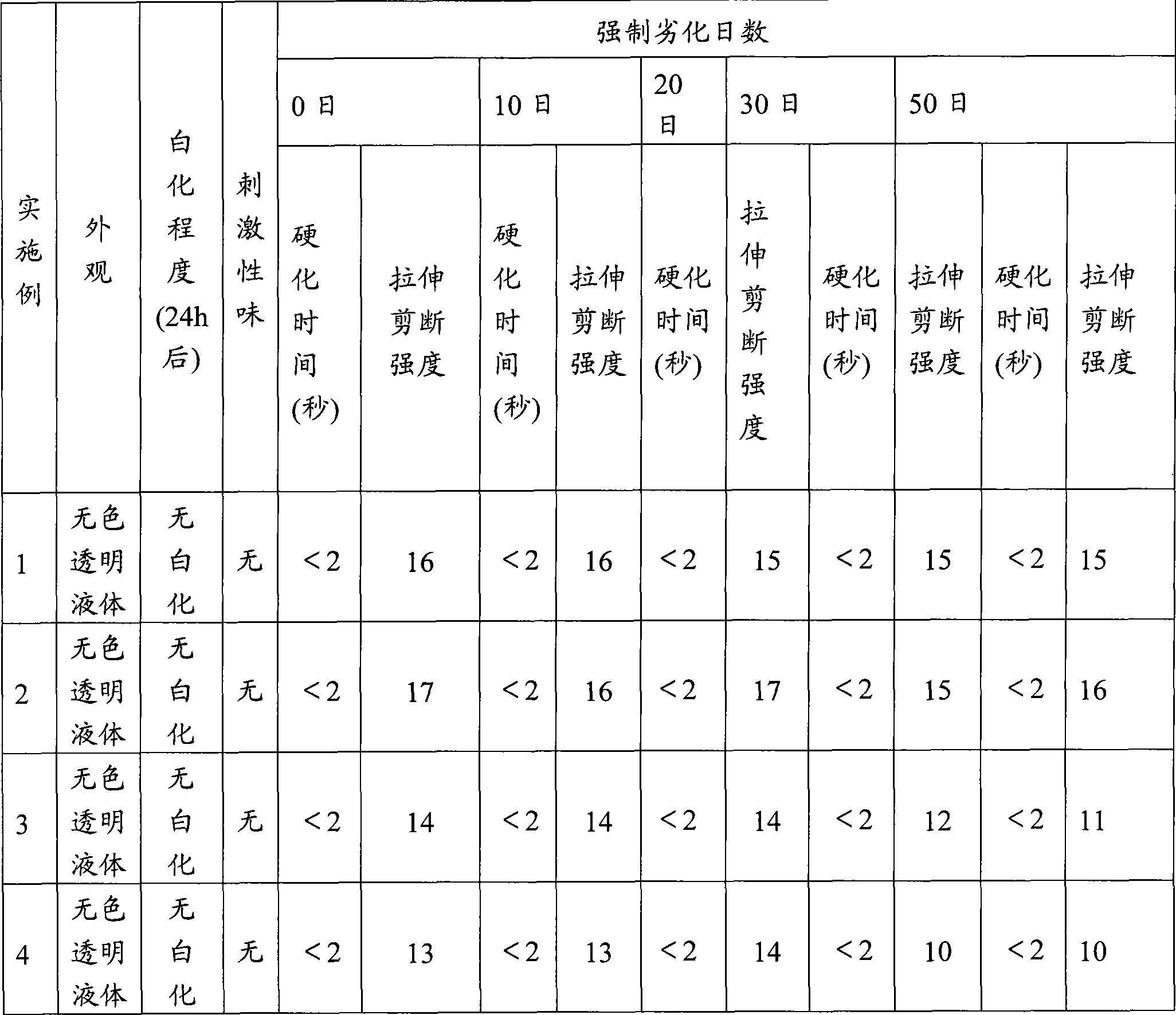

Examples

Embodiment 1

[0022] Add 60 parts by weight of paraformaldehyde, 200 parts by weight of toluene, and 0.2 parts by weight of piperidine into a four-necked flask equipped with a stirring dish, a thermometer, and a dropping funnel, and add 314 parts by weight of α-ethoxylate dropwise while stirring at 80°C. Ethyl cyanoacetate was refluxed to react to obtain a condensate. After cooling the reaction liquid to room temperature, add 300 parts by weight of 1% p-toluenesulfonic acid aqueous solution, vibrate, and separate into two layers after standing still, separate the oil layer, and distill the toluene in the oil layer under reduced pressure, and put it in the reaction flask Add hydroquinone and P to the condensate 2 o 5 3 parts by weight each, decompressed to a pressure of 3-5 mmHg, and depolymerized by heating at 160° C. to obtain 272 parts by weight of crude monomer with a product purity of 96.8%. Subsequently, P was added to the crude monomer 2 o 5 and 0.5% of hydroquinone, and then dist...

Embodiment 2

[0024] Using the device under the same conditions as in Implementation 1, add 60 parts by weight of paraformaldehyde, 300 parts by weight of benzene, and 1.6 parts by weight of piperidine, and drop 416 parts by weight of α-methoxyethyl cyanoacetate at 85°C , Reflux to make it react to obtain a condensation liquid. After the condensed liquid was washed twice with 200 parts by weight of water, benzene in the layer was distilled off under reduced pressure. Then, adding P to the condensate 2 o 5 and 5 parts by weight of hydroquinone, depolymerized by heating under reduced pressure at 200° C. to obtain 385 parts by weight of crude monomer with a product purity of 95.5%. Add P to the crude monomer 2 o 5 and 0.5% of hydroquinone, and then distilled to obtain 332 parts by weight of α-methoxy cyanoacrylate with a purity of 98.6%. Add SO to this compound 2 40ppm and 120ppm hydroquinone to prepare the adhesive.

Embodiment 3

[0026] Using the device with the same conditions as in Implementation 1, add 86 parts by weight of 37% formaldehyde solution, 300 parts by weight xylene, 0.1 part by weight p-toluene sulfonic acid, drop 240 parts by weight α-propoxyl at 85°C Ethyl cyanoacetate was refluxed to react to obtain a condensate. After the condensate was washed with 200 parts by weight of a 0.5% sulfuric acid aqueous solution, xylene in the oil layer was removed under reduced pressure to obtain a condensate. Then add P to the condensate 2 o 5 and 3 parts by weight of hydroquinone, depolymerized under reduced pressure and heated at 190°C to obtain 228 parts by weight of crude monomer with a product purity of 92.8%. Add P to the crude monomer 2 o 5 And each 1.0% of hydroquinone, then carry out distillation, then obtain the propoxy ethyl cyanoacrylate 203 weight parts that purity is 98.2%, add SO 2 30ppm, hydroquinone 92ppm, made adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com