Method for controlling valve opening in thermostat by engine cooling water channel temperature and oil-water thermostat

A technology of engine cooling and thermostat, which is applied in the direction of engine cooling, coolant flow control, engine components, etc. It can solve the problems of poor sensitivity and inability to automatically control the fan speed, and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

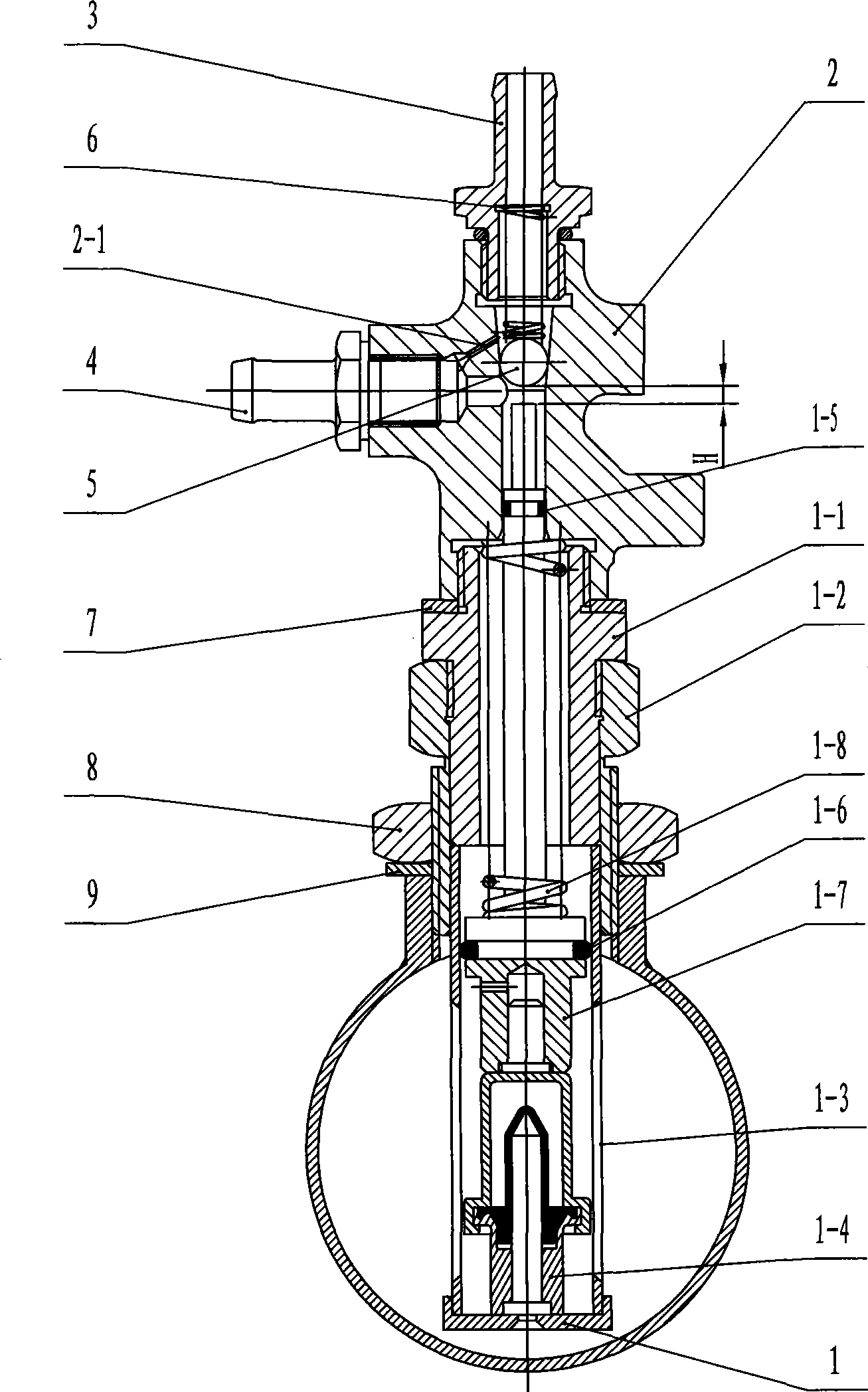

[0019] A method of controlling the opening of the valve in the thermostat body by using the temperature of the engine cooling water channel. It installs an oil-water thermostat on the engine cooling water channel, and uses the temperature of the engine cooling water channel to control the opening of the valve in the thermostat body. Automatically adjust the oil flow of the oil valve, thereby controlling the speed of the fan with the hydraulic coupling, so as to achieve the purpose of automatically controlling the temperature of the vehicle engine. The starting temperature of the oil-water thermostat is 70°C to 90°C.

[0020] As shown in the attached drawing: an oil-water thermostat, which includes a thermostat bushing assembly 1 and a thermostat body 2 . Thermostat bushing assembly 1 consists of threaded joint 1-1, thermostat bushing joint 1-2, thermostat bushing 1-3 and temperature sensing body 1 installed in thermostat bushing 1-3 -4 and thermostat ejector rod 1-7. The thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com