Double impeller ventilating apparatus with rubber pipe wind pipe

A ventilation device and double impeller technology, which is applied in the ventilation of mines/tunnels, non-variable pumps, mining equipment, etc., can solve the problems of large volume, difficulty in disassembly and transportation, and easy corrosion, so as to improve the efficiency of ventilation and separation. The effect of convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

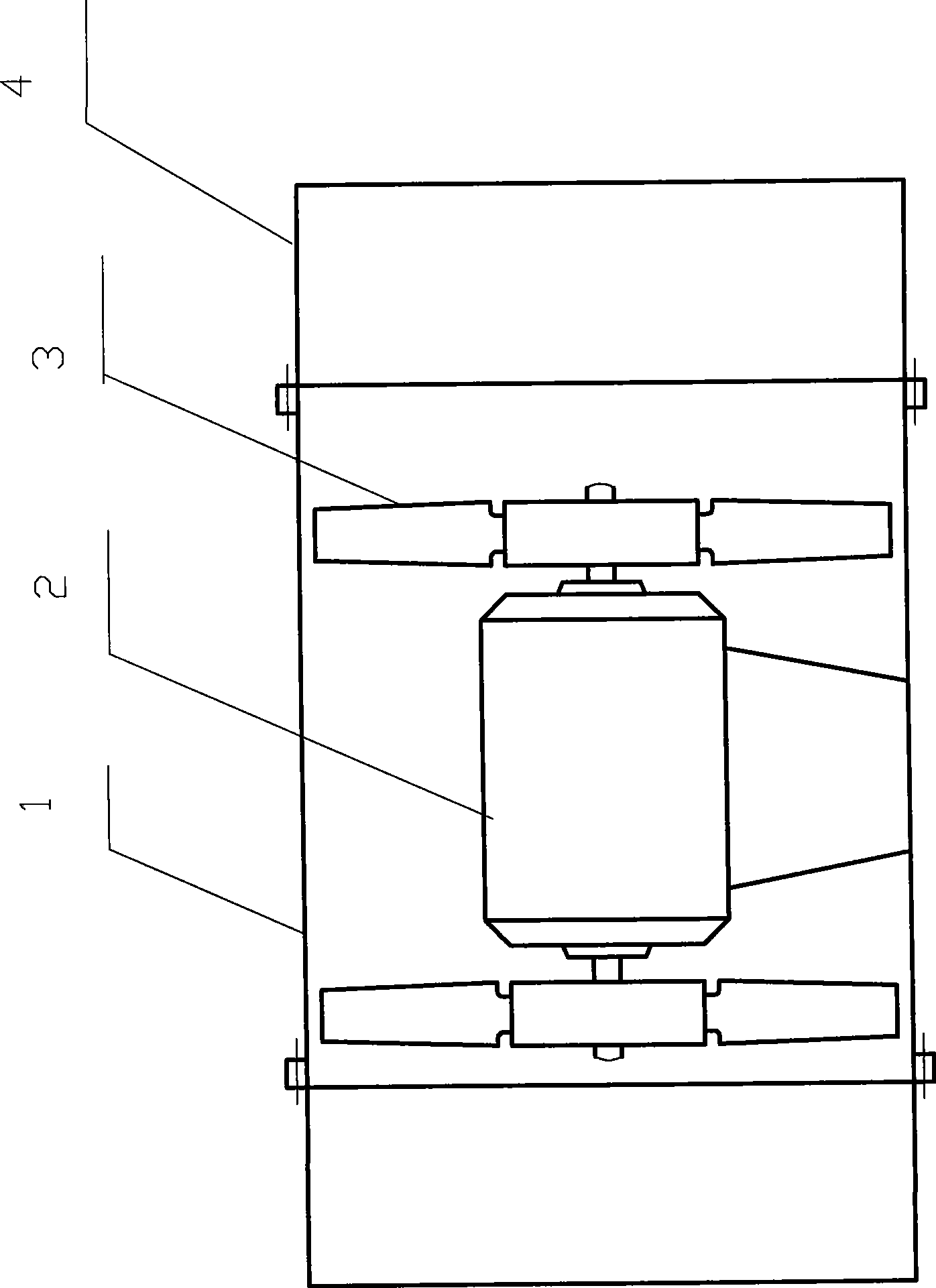

[0024] A double-impeller ventilation device with a rubber hose blower, including a casing 1 and a motor 2 inside the casing, wherein rubber hose blowers 4 are respectively installed at both ends of the casing; Rotating fan impeller3. The diameter of fan impeller 3 is 180 millimeters, and the distance between the fan impellers 3 at motor shaft two ends is 130 millimeters, and the radial clearance between air duct impeller 3 and casing 1 is 10~15 millimeters. Described sebific hose blower 4 is the PVC pipe of wall thickness 4 millimeters.

[0025] When working, start the motor, and the motor will drive the fan impeller to rotate in the casing through the transmission device. Under the action of atmospheric pressure, the external air will continuously flow into the fan impeller from the suction port along the rotation axis through the hose fan cylinder, and the rotating impeller makes the fan impeller rotate. The incoming air gains energy, which accelerates another fan wheel, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com