Chromatography tank for artemisinin extraction and efficient pressurized chromatography method thereof

A technology of artemisinin and extract, applied in separation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of long production time and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

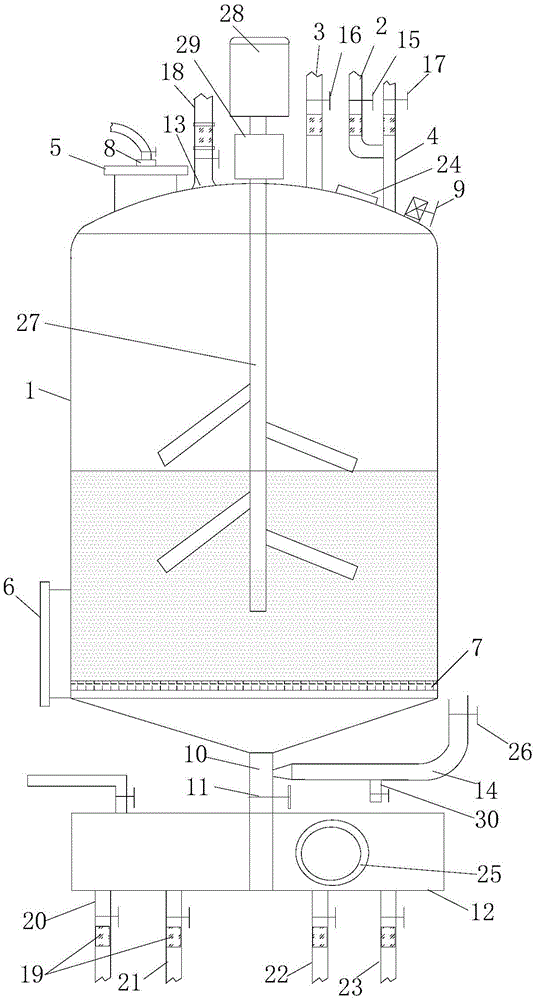

[0024] refer to figure 1 , propose an embodiment of the present invention, this embodiment comprises tank body 1 and solvent oil inlet pipe 2 connected to the upper part of the tank body, extraction solution inlet pipe 3, eluent inlet pipe 4, the top of the tank body is provided with a feed door 5. There is a discharge door 6 on the lower side of the tank body, a support screen 7 on the bottom of the tank body, a compressed air inlet 8 and an air emptying valve 9 on the top of the tank body, and the main discharge pipe is connected to the bottom of the tank body 10. A main valve 11 is installed on the main exhaust pipe, and the lower end of the main exhaust pipe is connected to a drug inspection transfer tank 12, and the drug inspection transfer tank 12 is connected to a plurality of classification pipes. The top of the tank body is also provided with a solvent recovery port 13, and the main discharge pipe 10 is connected with a steam inlet pipe 14; the solvent oil inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com