Modeling method for boiler combustion optimization

A technology of boiler combustion and modeling method, which is applied in the directions of controlled combustion, comprehensive plant control, and comprehensive plant control, and can solve problems such as optimization, inability to achieve, and limitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

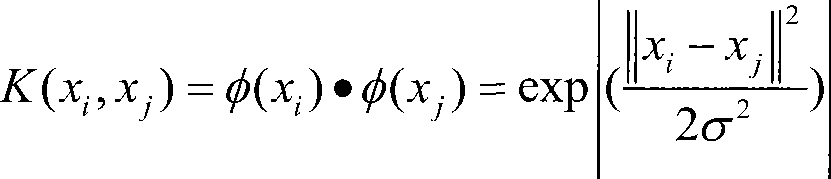

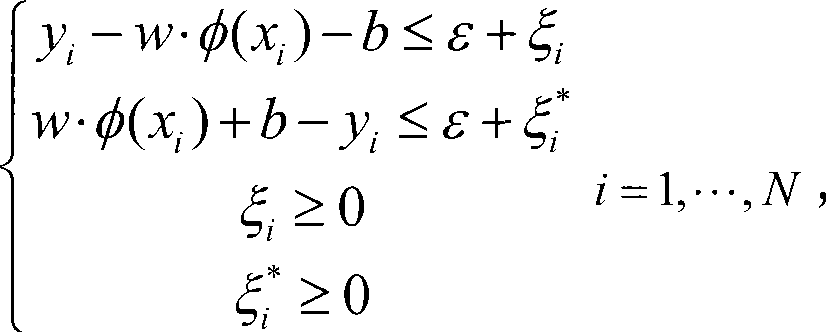

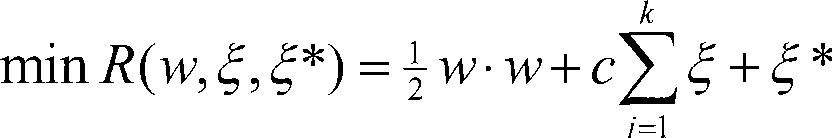

Method used

Image

Examples

Embodiment Construction

[0045] A modeling method for boiler combustion optimization, the specific steps are:

[0046] According to the requirements of boiler combustion optimization, determine the operating parameters that the database needs to collect (mainly including air distribution, powder feeding, oxygen, coal quality and load, etc.), and related indicators that characterize the combustion state of the boiler (mainly including boiler efficiency, tail gas composition, etc.) and CO concentration near the water wall, etc.).

[0047] (1) Establish a real-time database, and collect boiler operating parameters and related data representing boiler combustion characteristics in sections according to the boiler load.

[0048] According to the similarity of the combustion state under different boiler load conditions, a real-time operation database of boilers under n (n≥3) load segments is established. As an example, four segments are taken here:

[0049] ①Over 85% load database;

[0050] ②85%-70% load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com