Clamper of cold upsetting tester used for titanium alloy wire materials

A technology of titanium alloy wire and test equipment, which is applied in the direction of measuring equipment, analysis materials, instruments, etc., can solve the problems of twisted forging, oblique forging height, non-compliance with requirements, uncontrollable upsetting speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

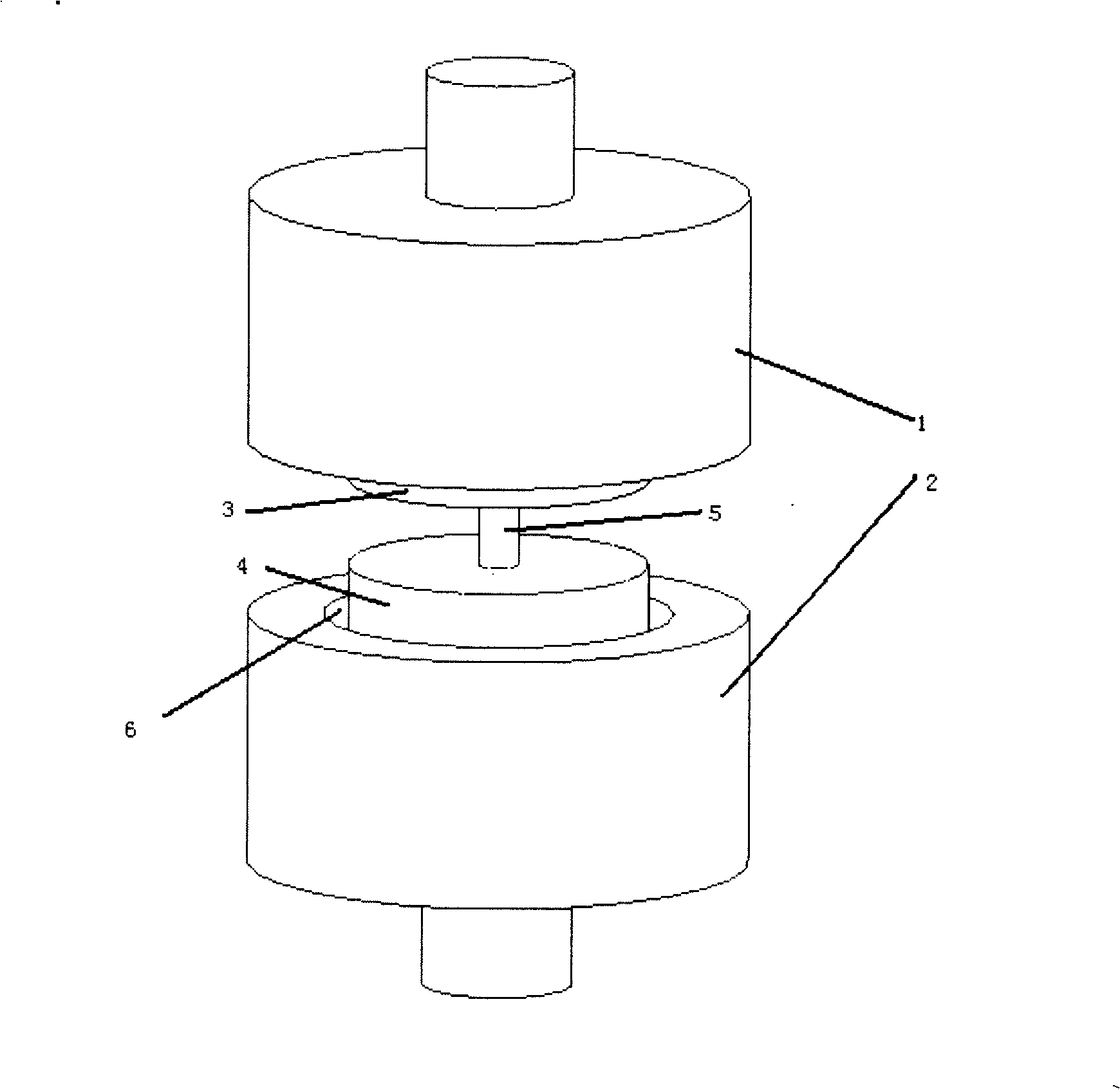

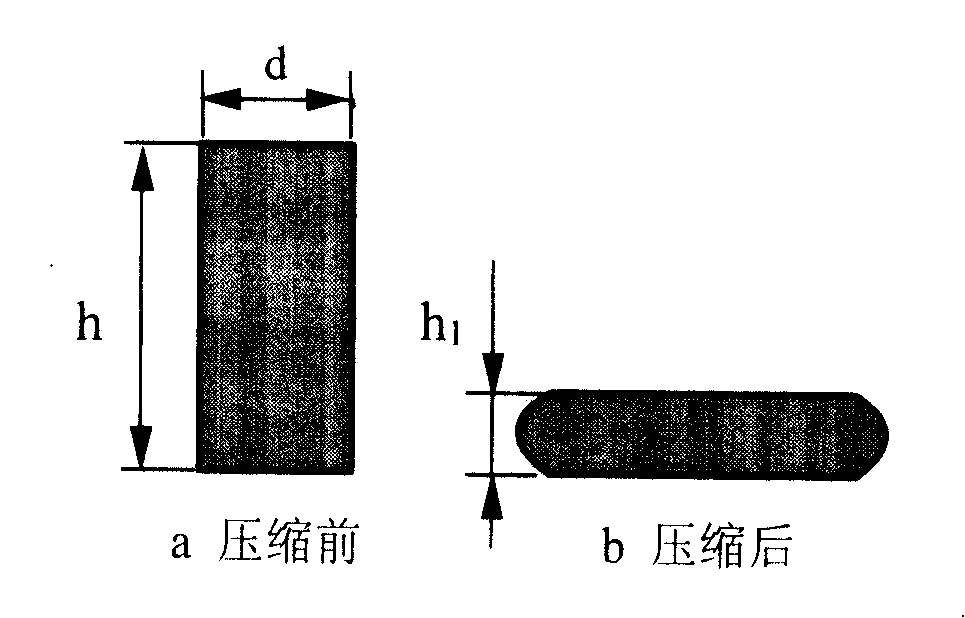

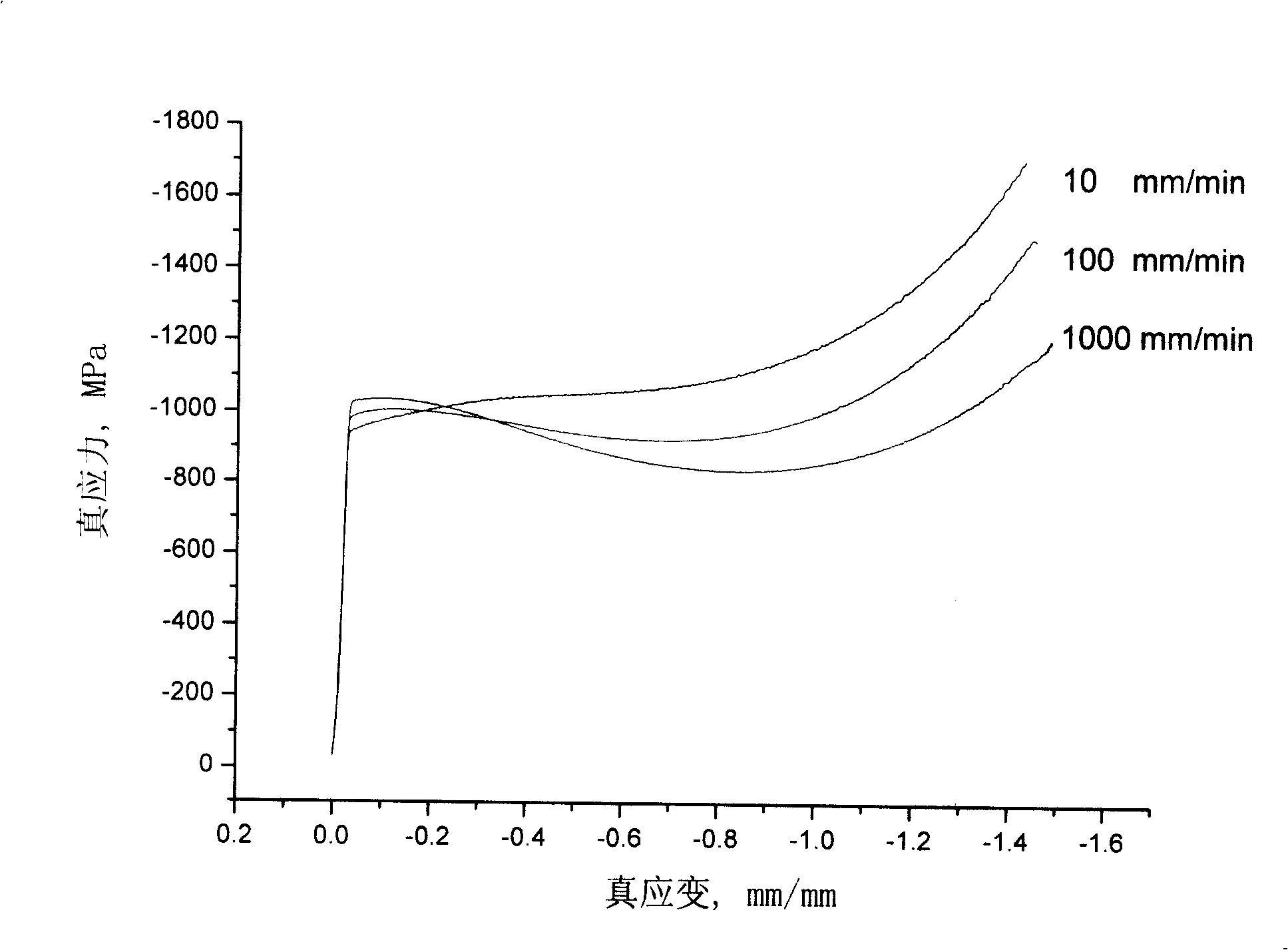

[0015] According to the requirements, special research and tests have been carried out by adopting the technical scheme of the present invention for 4 kinds of titanium alloy wires with diameters within 8mm, as shown in the attached Figure 1~3 As shown, the fixture of the cold upset test device for titanium alloy wire includes an upper fixture 1 and a lower fixture 2, and the material mechanical performance testing machine is connected with the upper and lower fixtures through large-diameter threads, and is characterized in that: A groove 6 is processed at the center of the support surface of the upper fixture 1 and the lower fixture 2. The depth of the groove 6 is 5 mm. In the groove 6, an upper support plate 3 and a lower support plate 4 are placed. The upper support plate 3 and the lower support plate The support plate 4 is a cylinder with a thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com