Portable metallic material tensile stress etching apparatus and method

A technology of tensile stress and metal materials, which is applied in the field of portable metal material tensile stress corrosion devices, can solve the problems of unsatisfactory multiple application of prestress, timely observation of selective corrosion, large volume, inconvenient movement, etc., and achieve effective Conducive to the analysis of test results, simple operation and convenient loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The portable metal material tensile stress corrosion device of the present invention will be described in detail below in conjunction with the accompanying drawings.

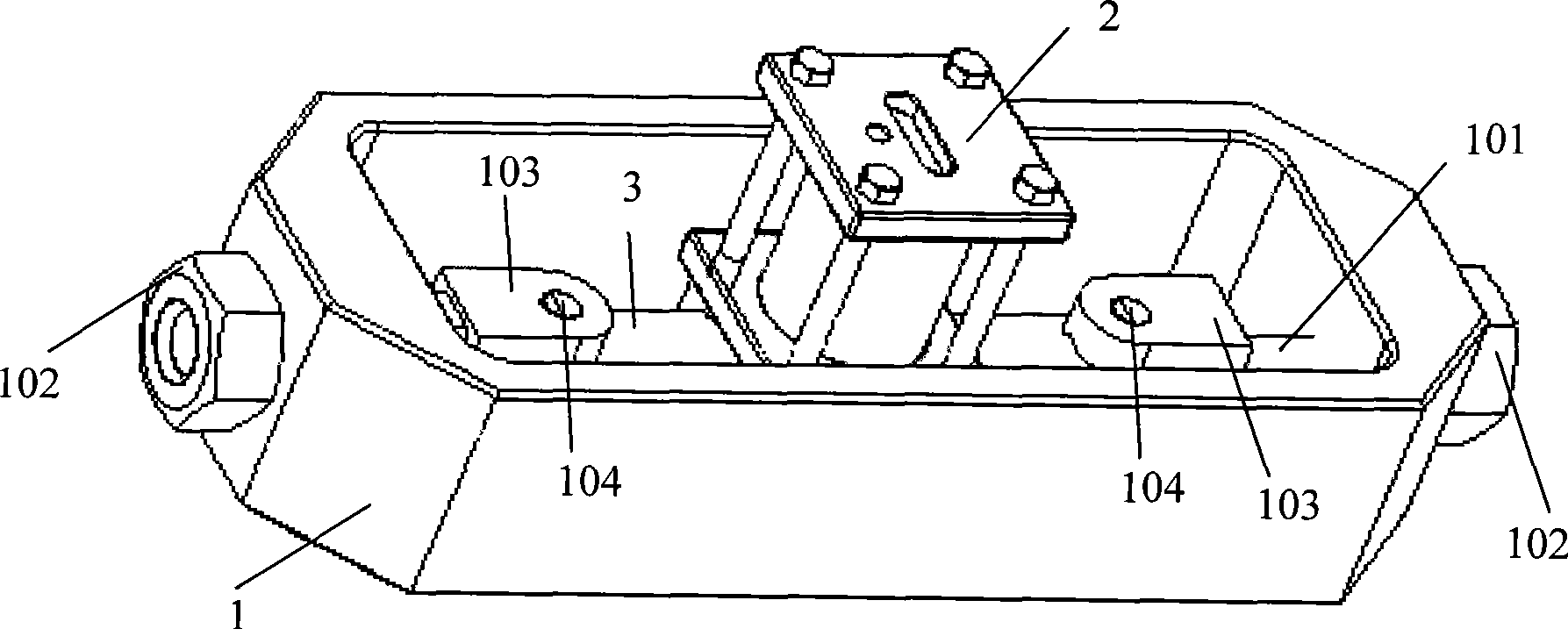

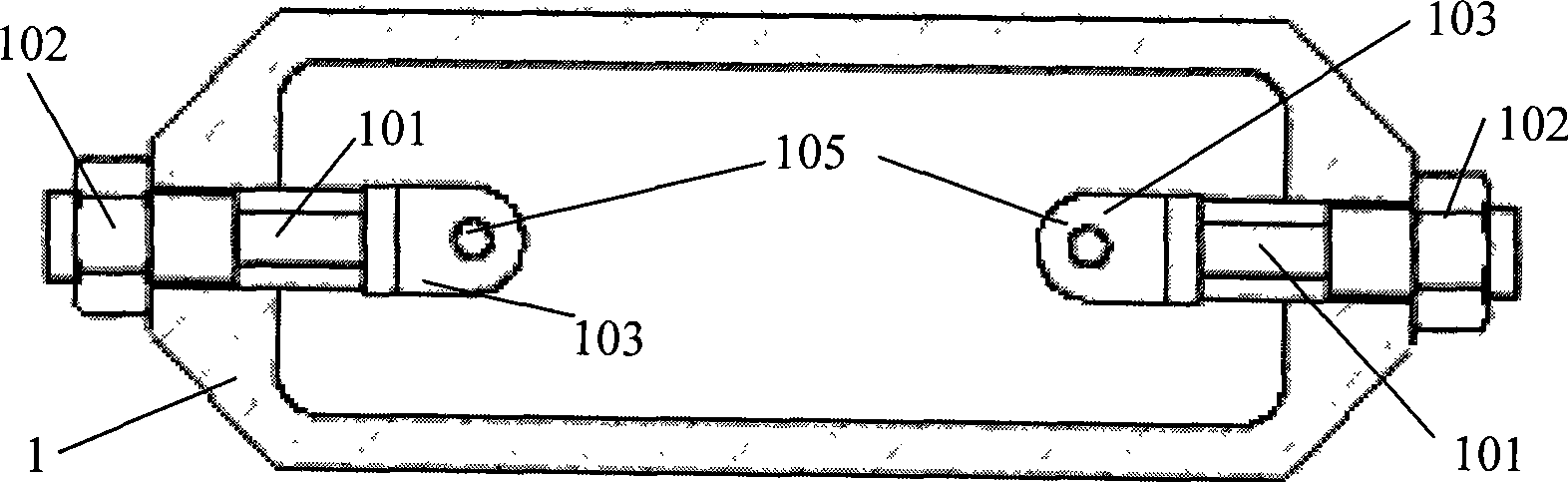

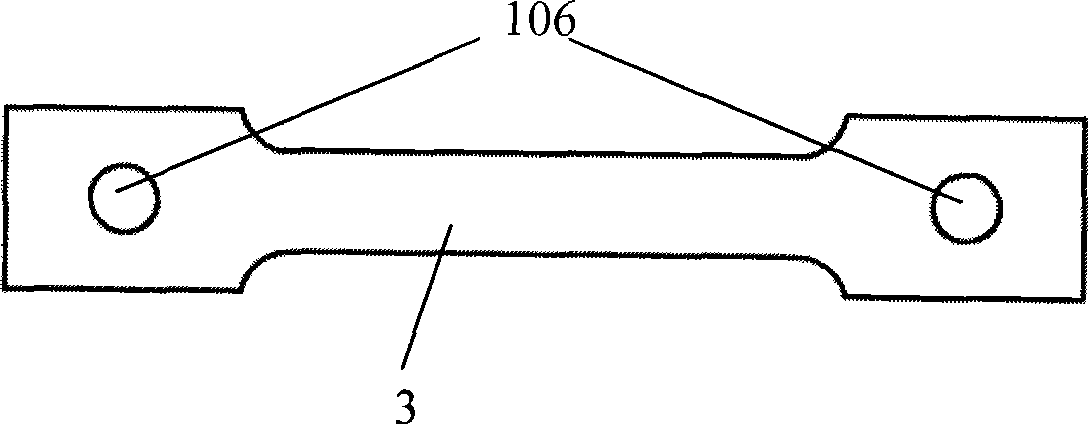

[0019] A portable tensile stress corrosion device for metal materials. This device can not only selectively corrode stress tensile samples, but also test electrochemical parameters under the joint action of stress and corrosion environment, such as figure 1 As shown, the device includes a loading body device 1 and a corrosion test tank 2 . The loading main device 1 is used to fix and stretch the tensile sample 3, such as figure 2 As shown, the loading main body device 1 is a quadrilateral frame structure processed by metal stainless steel materials. The length direction of the frame structure is parallel and coaxially provided with two loading rods 101. One end of the loading rod 101 passes through two loading nuts 102. It is fixed on the frame structure of the loading main body device 1 . The other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com