Protective film coating method of electronic product casing

A technology for electronic products and protective films, which is applied in the field of applying protective films to the shells of electronic products. It can solve the problems of applying protective films, low efficiency of manual film application, difficulty in unifying the size of the interception, and the location of the application, so as to achieve production High efficiency, accurate size and overlay position, uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] A protective film coating method for an electronic product casing, comprising the steps of:

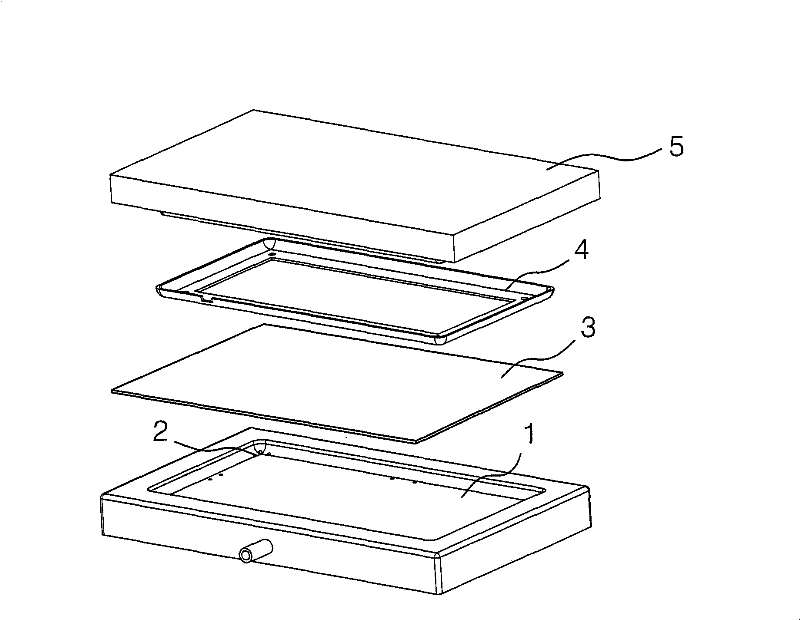

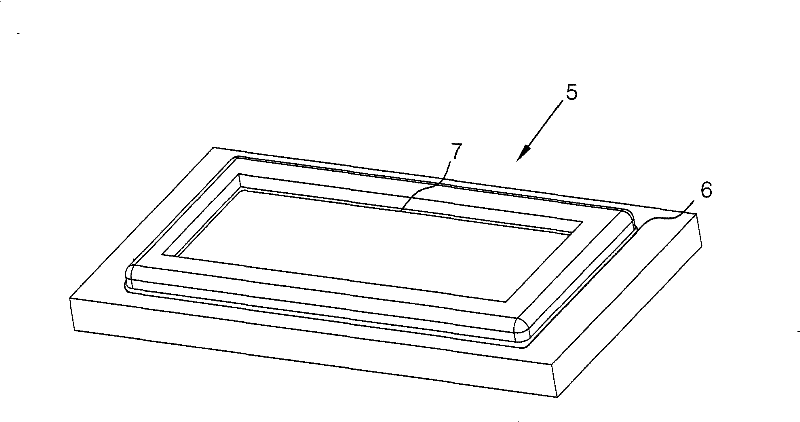

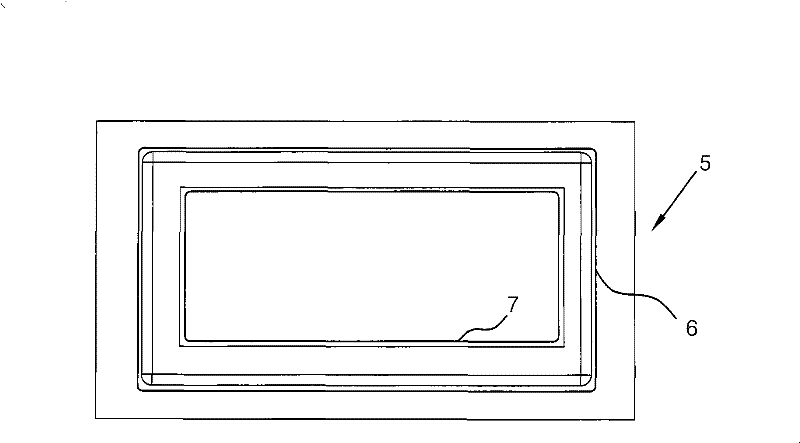

[0022] as attached figure 1 As shown, the equipment for attaching the protective film to the shell of the electronic product includes an upper mold 5 and a lower mold 1. The upper part of the lower mold 1 is provided with a pit similar in shape to the shell 4 of the electronic product. There are several pits in the pit. The air extraction hole 2 is connected with the vacuum pump. There are heating devices on the upper mold 5 and the lower mold 1 respectively. The housing 4 of the electronic product is often provided with structures such as threaded holes or slots due to assembly requirements, and the parts of these threaded holes and slots do not need to be pasted. as attached figure 2 And attached image 3 As shown, the lower part of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com