Ultralow-odor polyurethane matte varnish and preparation method thereof

A technology of polyurethane and clear topcoat, applied in the field of coatings, which can solve problems such as incomplete volatilization of organic solvents, threats to human health, and residual pungent odors, and achieve the effects of low application odor, smooth coating film, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

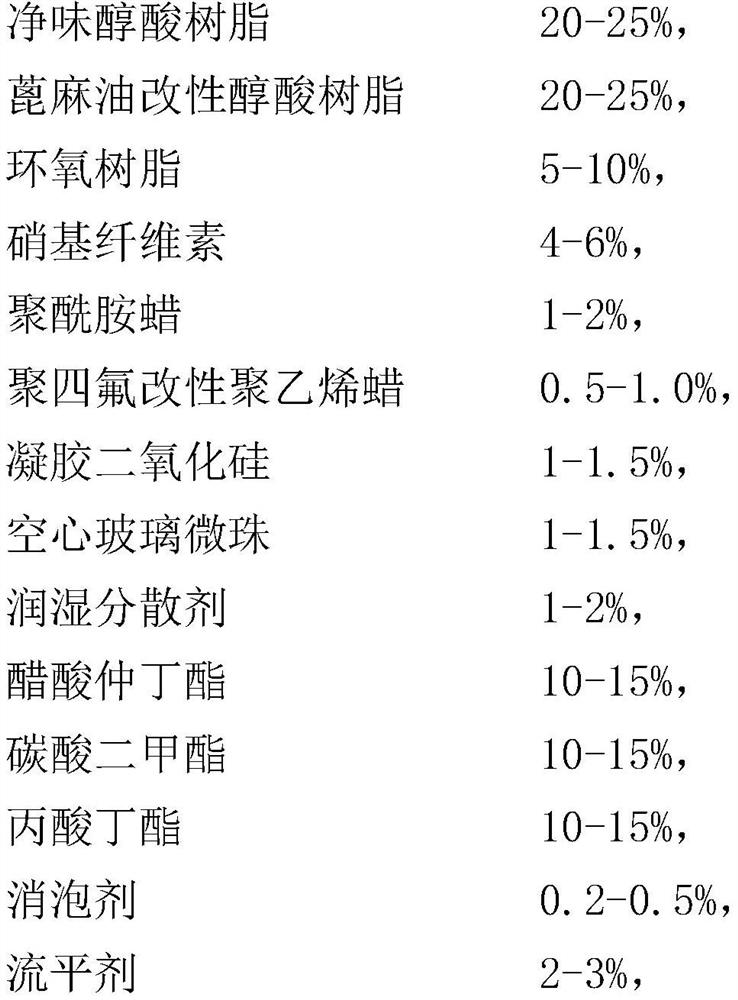

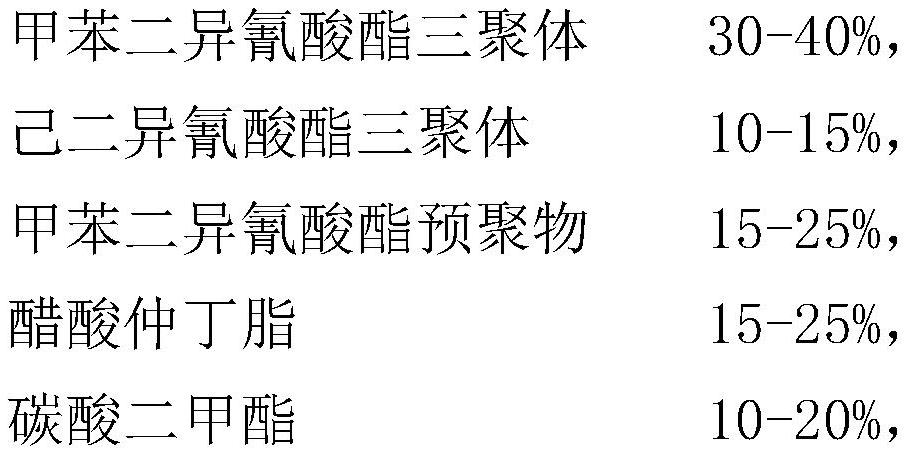

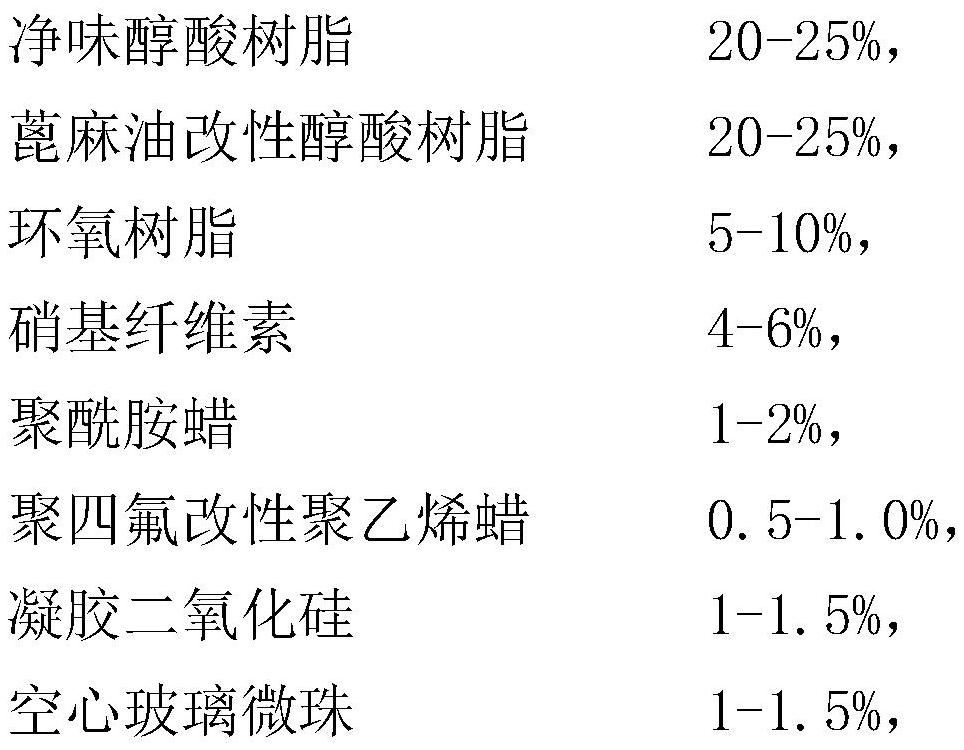

[0038] The following table is the formula table (unit: %) of 4 examples of ultra-low odor polyurethane matt clear finish paint of the present invention.

[0039]

[0040] A kind of preparation method of described ultra-low odor polyurethane matte varnish, comprises the following steps:

[0041] A. Preparation of Component A

[0042] a. Mix nitrocellulose with lipid solvent, soak for 2-3 hours, stir at a speed of 300-500r / min, until all materials are dissolved and become a transparent liquid;

[0043] b. Add net taste alkyd resin, castor oil modified alkyd resin, epoxy resin, gel silica, polyamide wax, polytetrafluoroethylene modified polyethylene wax, hollow glass microspheres, wetting and dispersing agent and Defoamer, stir at 1200-1400r / min for 10-15min to fineness≤20μm;

[0044] c. Add the remaining components, stir at a speed of 500-800r / min for 10-15min, mix well and pass through a 200-mesh sieve to obtain component A;

[0045] B. Preparation of B component

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com