Bobbin detector

A detector and coil paper technology, applied in the field of packaging, can solve the problems of discontinuous paper supply, product loss, packaging accidents, etc., achieve the effect of wide application, beautiful appearance, and ensure the quality of paper supply and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

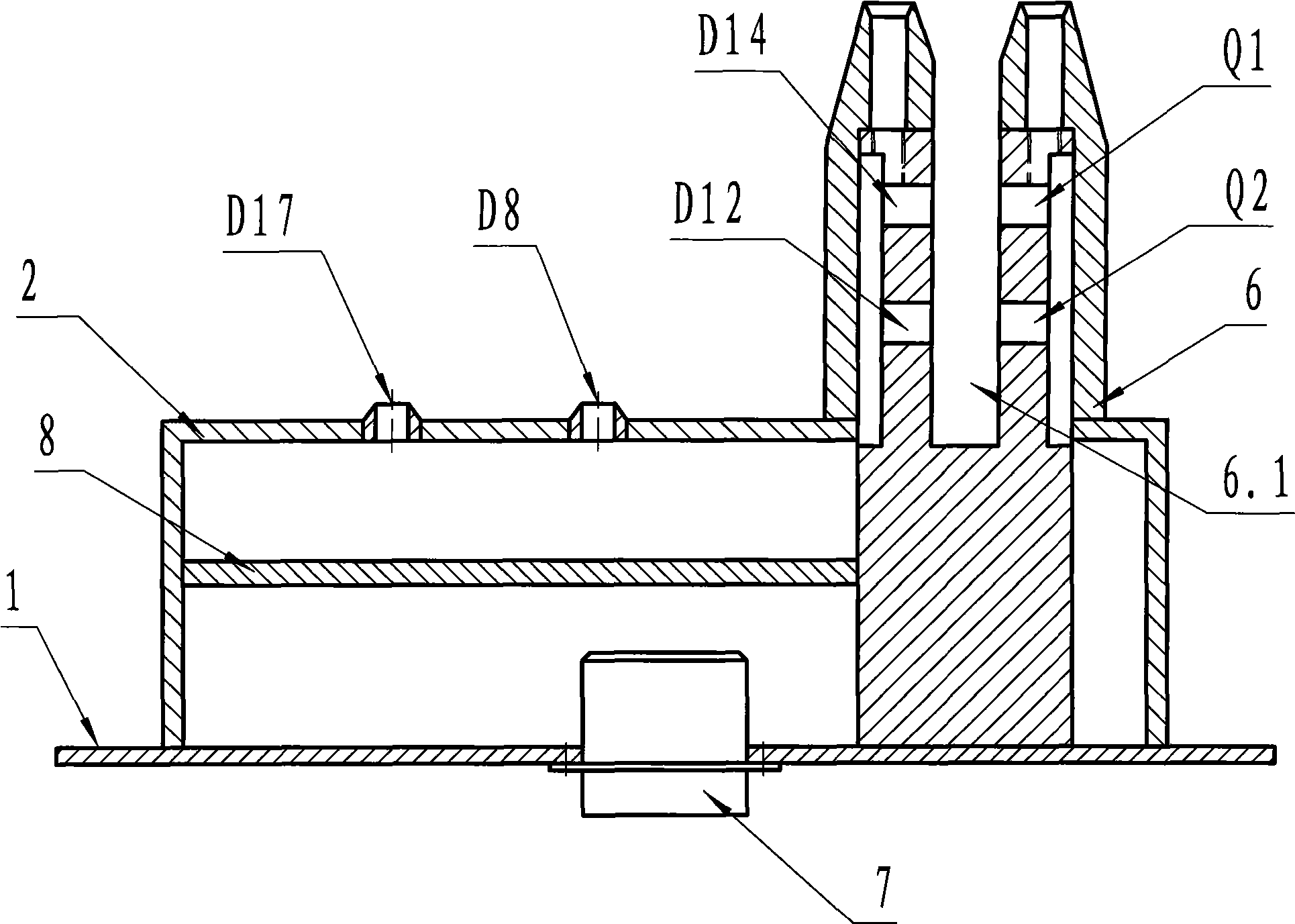

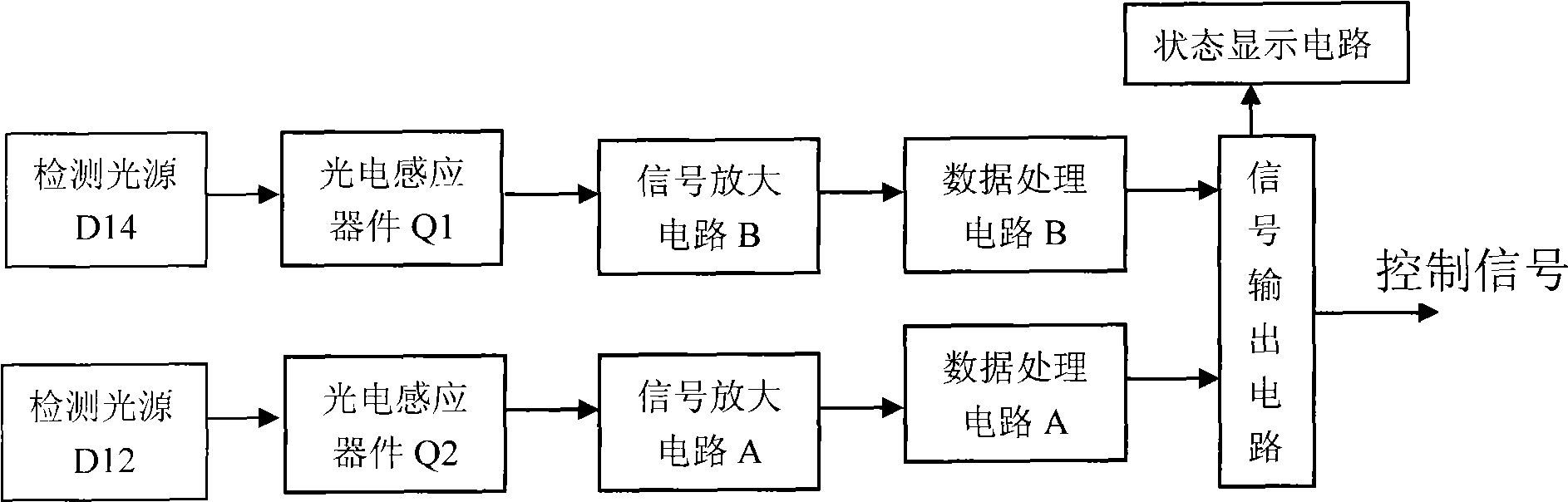

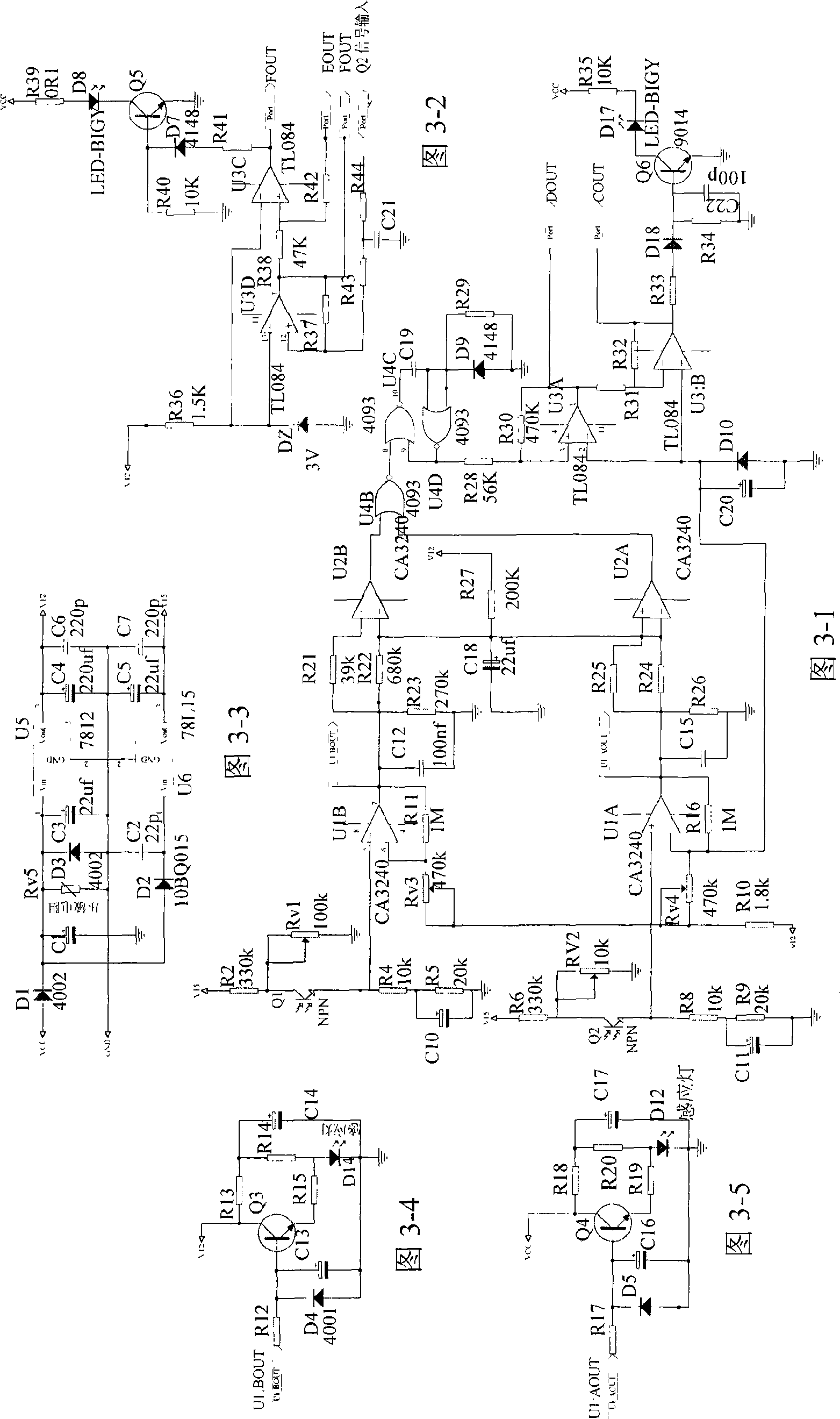

[0014] The implementation of the present invention will be described below with reference to the accompanying drawings. figure 1 It is a schematic structural diagram of an embodiment of the paper coil detector provided by the present invention. This embodiment is a detector for detecting the paper feeding quality and paper feeding status of an automatic rapid production line. It can be seen from the figure that the paper coil detector is composed of a base 1, a casing 2, a status display lamp D17, a detection light source D14, D12, photoelectric sensing devices Q1, Q2, a detection head 6, an outlet plug-in 7, and a circuit board 8. The detection light sources D14 and D12 and the photoelectric sensing devices Q1 and Q2 are installed on both sides of the rectangular groove 6.1 at the front end of the detection head. When the detected wrapping paper passes normally through the middle of the rectangular slot at the front end of the detection head 6, the detector has no control ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com