Vehicle waste gas driving three-phase generator

A generator and three-phase technology, applied in the direction of machines/engines, electromechanical devices, electrical components, etc., can solve the problems of complex structure and high cost of voltage-stabilized permanent magnet motors, and achieve compact structure, less reactive power loss, and fewer turns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

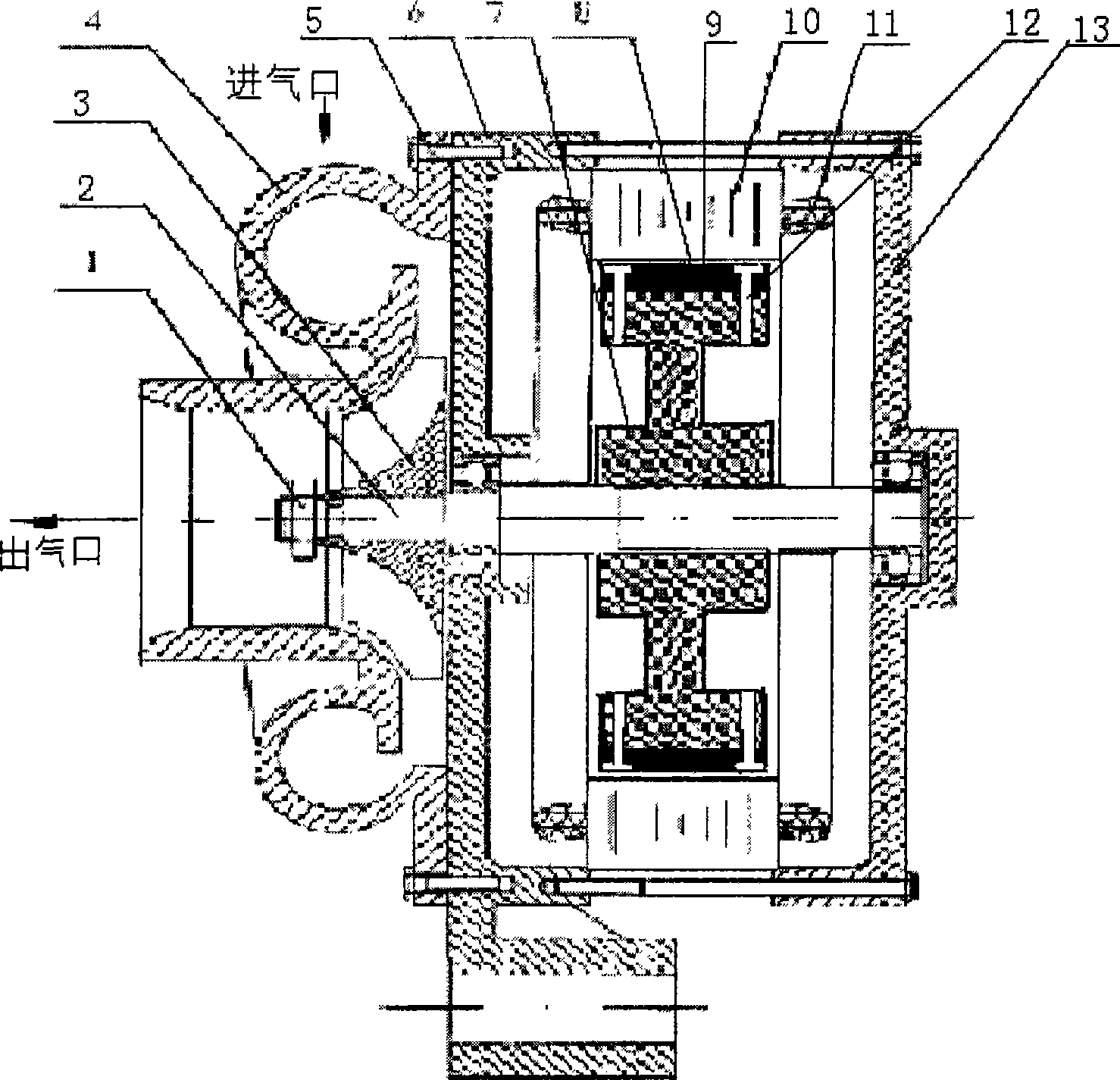

[0018] In the embodiment: 1. nut 2. shaft 3. turbine 4. volute 5. bolt 6. rear cover 7. rotor core 8. permanent magnet 9. pole shoe 10. stator core 11. armature winding 12. Non-magnetic screw 13. Front cover

[0019] Below in conjunction with accompanying drawing, the present invention is described further:

[0020] The three-phase generator driven by vehicle exhaust gas is composed of a rotor, a stator, a front end cover 13, a rear end cover 6, a turbine 3, and a volute 4. The turbine 3 and the permanent magnet rotor are installed on the shaft 2, and the turbine 3 is installed on the volute 4. The volute 4 is fixed on the rear end cover 6 of the generator through the bolt 5; the armature winding 11 of the stator is the same three-phase armature winding, and each phase of the three-phase armature winding All of them cross the three poles on the stator core 10 and insert the wires sequentially. The phase difference of the above-mentioned armature winding is 120 degrees. The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com