Automatic alarm device of fuel oil filter

A technology of automatic alarm device and fuel filter, applied in machine/engine, charging system, engine components, etc., can solve problems such as damage, breakdown of fuel filter, weak adhesion, etc., to achieve a wide range of applications , the effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

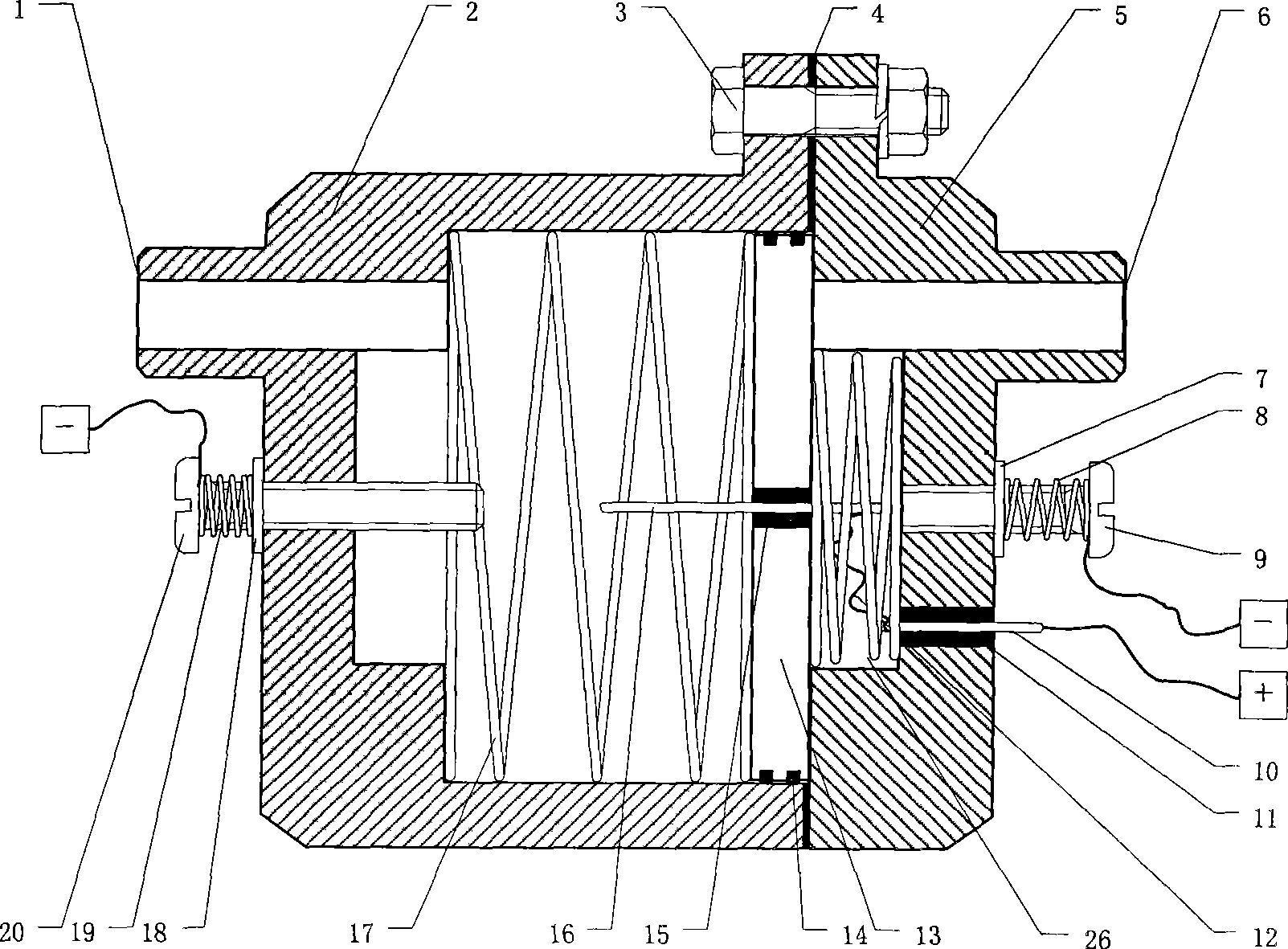

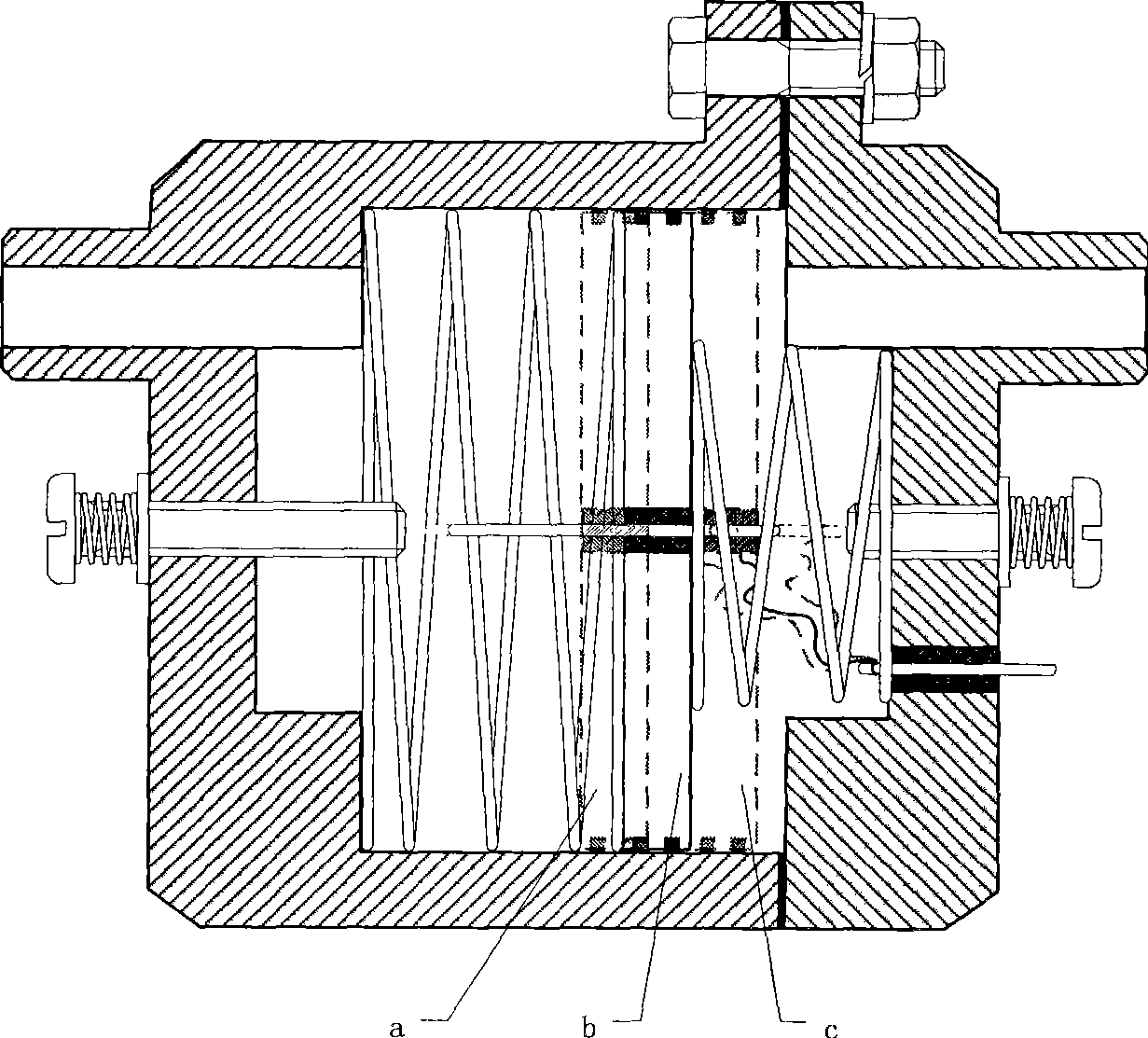

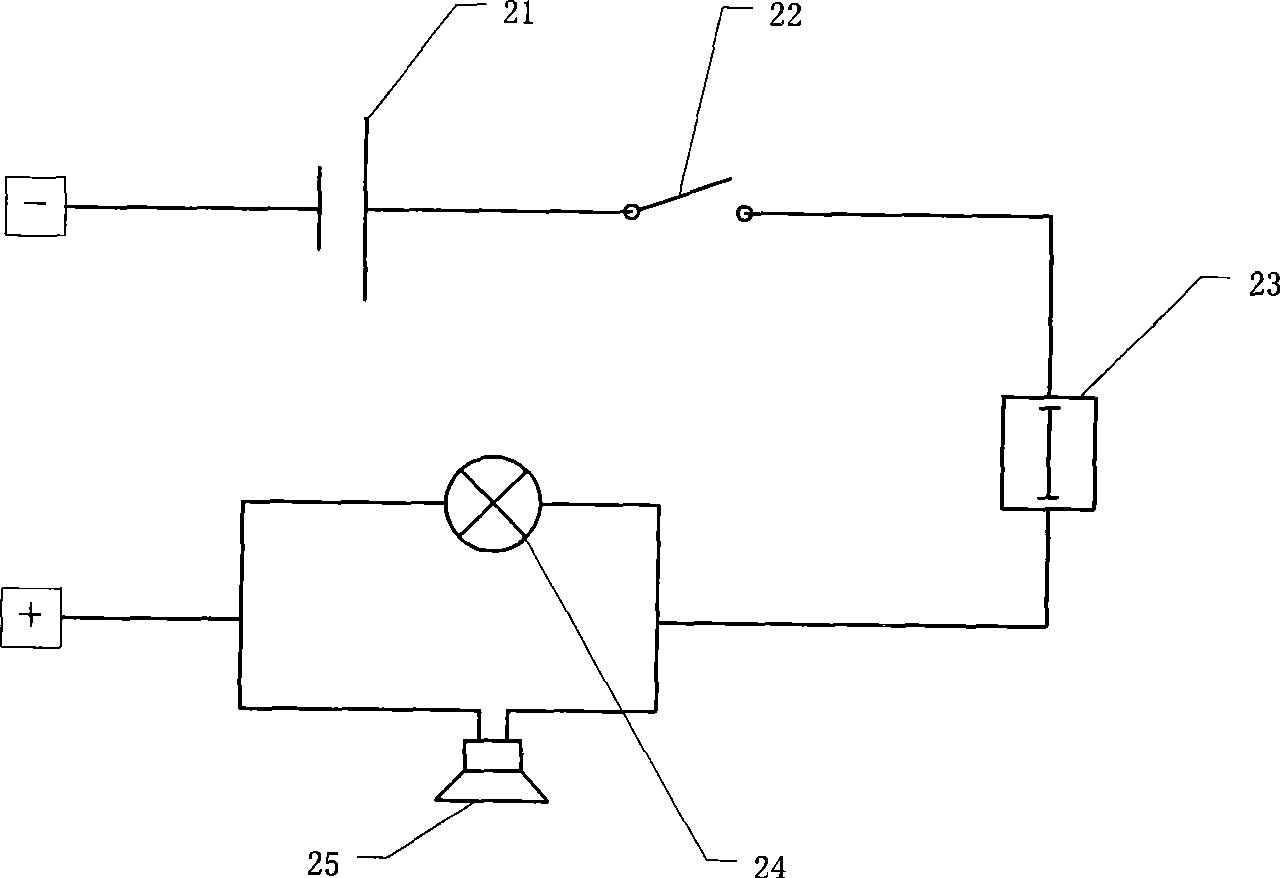

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0030] The fuel filter automatic alarm device in this embodiment includes a sensor; the sensor includes a pre-filtered fuel chamber housing 5 and a filtered fuel chamber housing 2, and the pre-filtered fuel chamber housing 5 and the filtered fuel chamber housing 2 are respectively arranged There are pre-filtered fuel inlet 6 and filtered fuel inlet 1; the front fuel chamber casing 5 and the filtered fuel chamber casing 2 are butted by bolt fasteners 4 to form a cavity, and a sealing ring 4 is arranged at the butt joint; a piston 13 is arranged in the cavity, A spring 17 and a spring 26 are respectively arranged between the two sides of the piston 13 and the inner walls at both ends of the cavity; the pre-filter fuel chamber casing 5 and the filtered fuel chamber casing 2 are provided with an adjusting conductive screw 9 and an adjusting conductive screw 20 penetrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com