Simulating device for solar cavity type heat absorber

A technology of simulating device and heat absorber, applied in the research field of tower solar thermal power generation, which can solve the problems of low heat flux density, high heat flux density, and inability to provide such a large heat flux density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

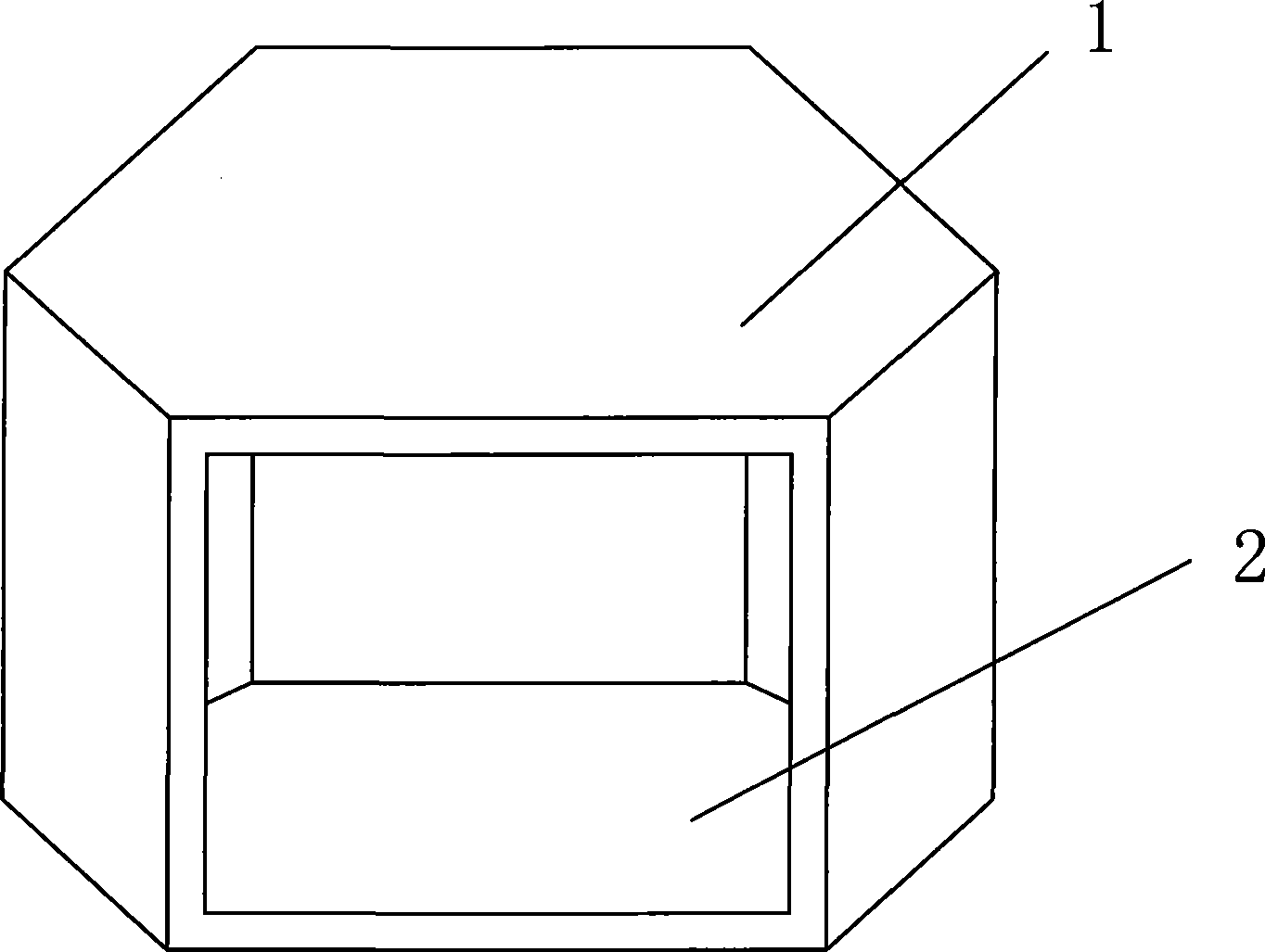

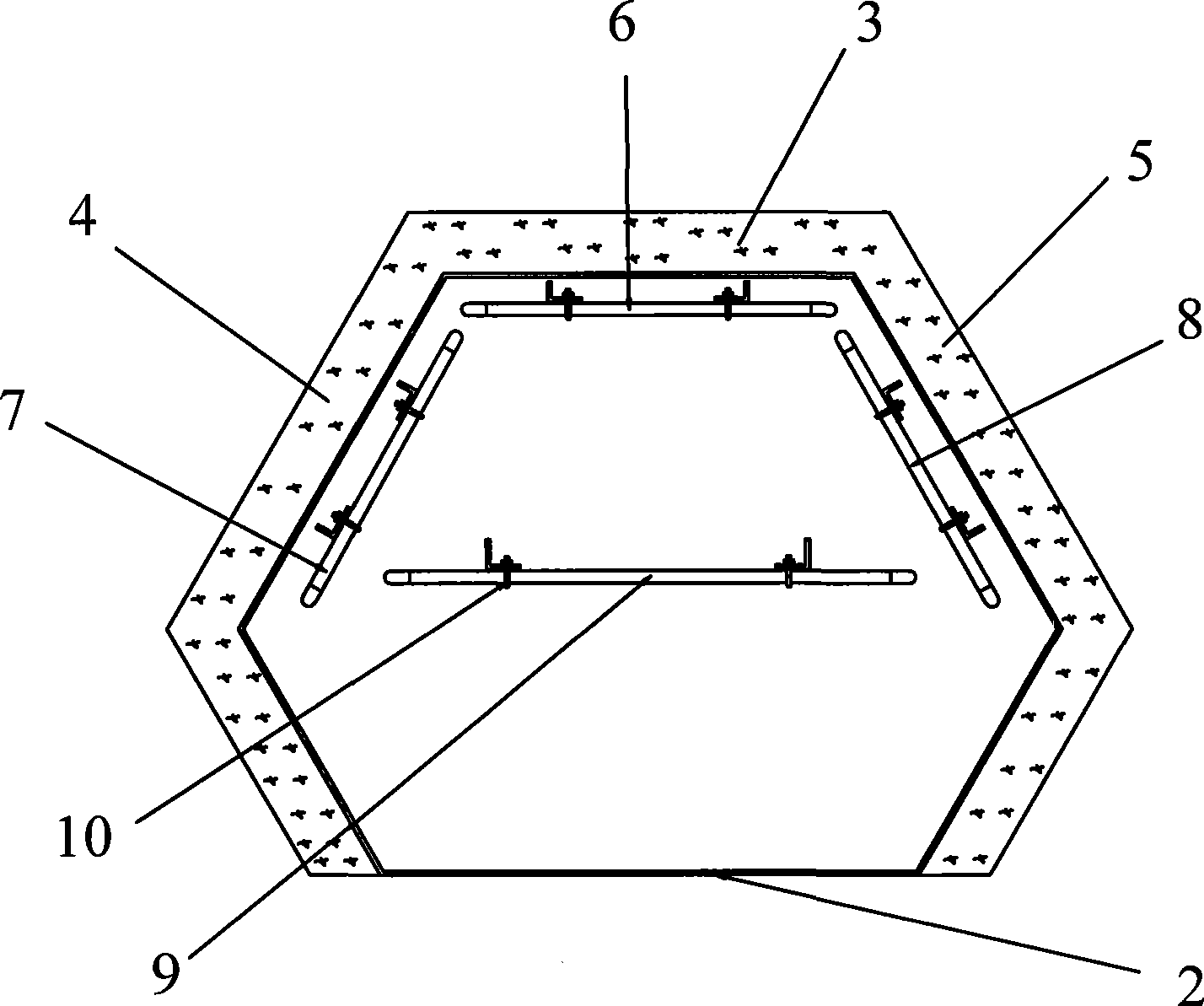

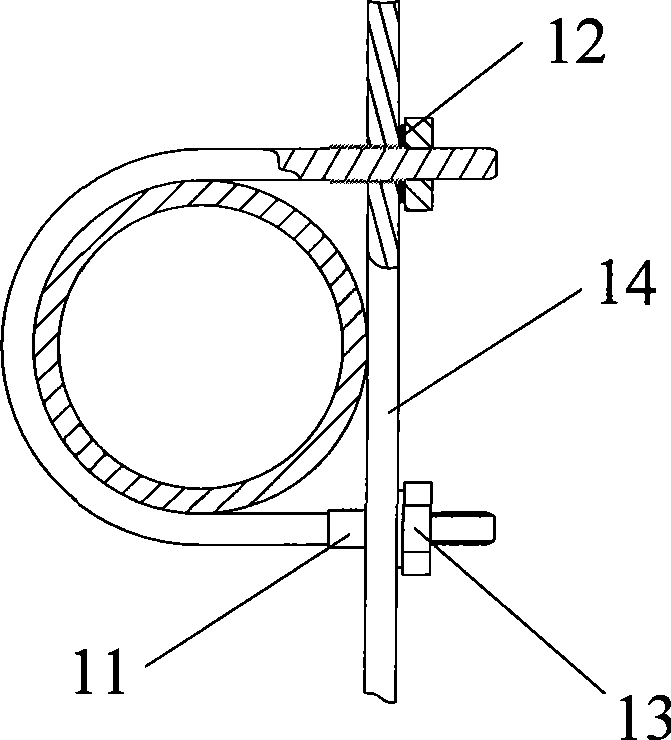

[0017] refer to figure 1 , figure 2 , The heat-absorbing cavity 1 is in the shape of a hexagonal column, and a daylight opening 2 is provided on one side thereof. The shell of the heat-absorbing cavity 1 is made of 304 steel plates, and the outside of the shell is wrapped with an insulating layer except the daylighting opening 2 . On the opposite side of the daylight opening 2 are the rear side wall 3, the left rear side wall 4 and the right rear side wall 5 of the heat-absorbing cavity 1. Boiling tubes 6, 7, 8 on the rear side, left rear side, and right rear side, and an overheating pipe 9 is arranged between the daylight opening 2 and the rear side wall 3.

[0018] The height of the daylighting opening 2 is relatively small, and the height of the wall directly behind the daylighting opening 2 is relatively large. The entire heat-absorbing cavity 1 is in a shape that gradually expands from the daylighting opening 2 to the rear. Boiling tubes 6, 7, 8 and overheating tube 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com