Simulating device for solar cavity type heat absorber

A technology of a simulation device and a heat absorber, which is applied in the research field of tower solar thermal power generation, can solve the problems such as the inability to provide such a large heat flux density, high heat flux density, and increased difficulty of the cavity heat absorber simulation experiment.

Inactive Publication Date: 2011-01-05

XI AN JIAOTONG UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the solar heat flux inside the cavity heat absorber has two notable features: one is that the heat flux is very large, generally above 100kW / m2, and the highest place can reach 500kW / m2, or even higher. Neither heating nor electric furnace wire heating can provide such a large heat flux density; the second is that the distribution of solar light spots in the cavity heat absorber is uneven, which makes the heat flux distribution uneven, and the rear of the cavity heat absorber facing the daylighting port The heat flux density on the wall is relatively the largest, while the heat flux density on several surfaces around the daylight opening is relatively the smallest

Therefore, it is more difficult to simulate the cavity heat absorber

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

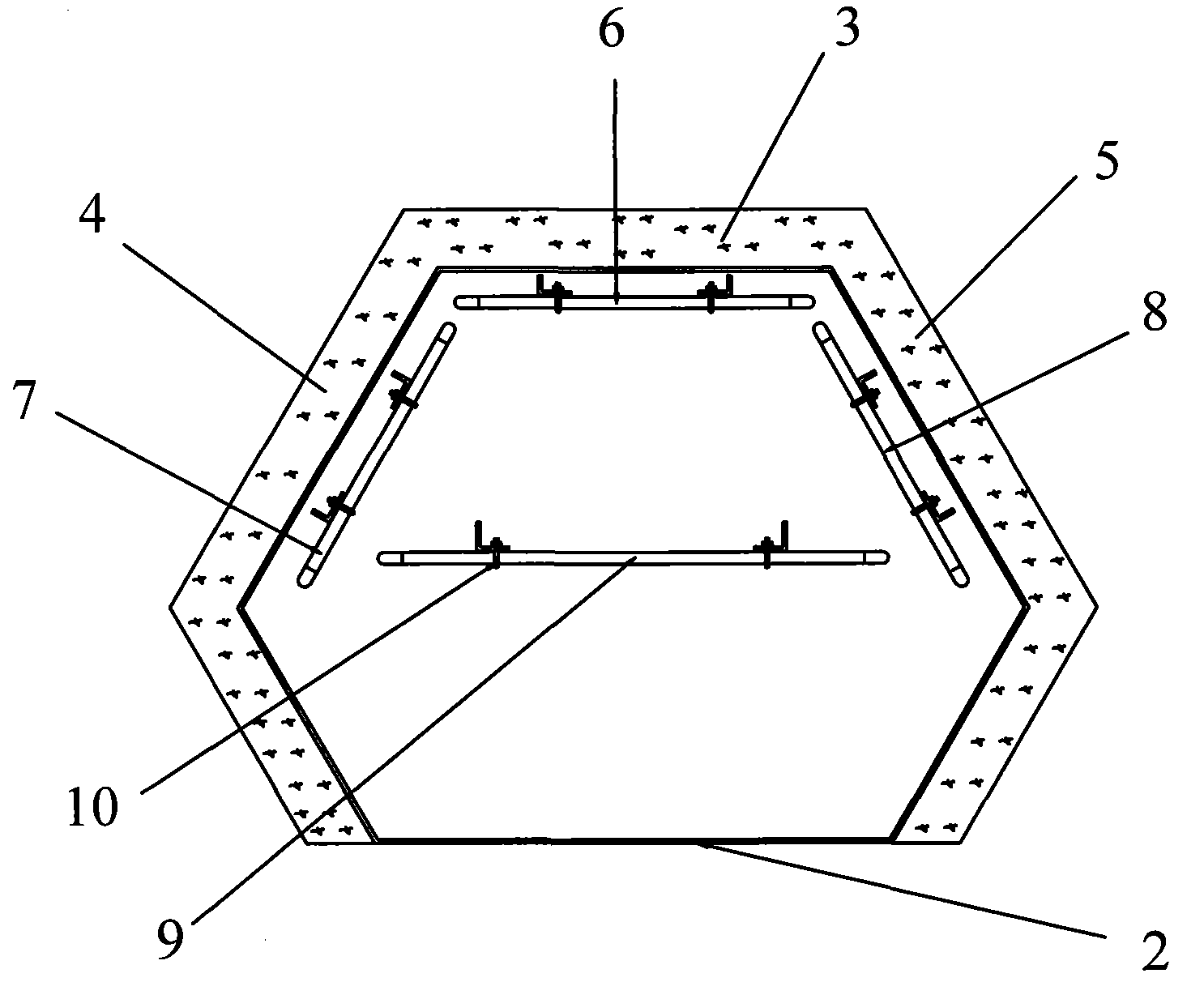

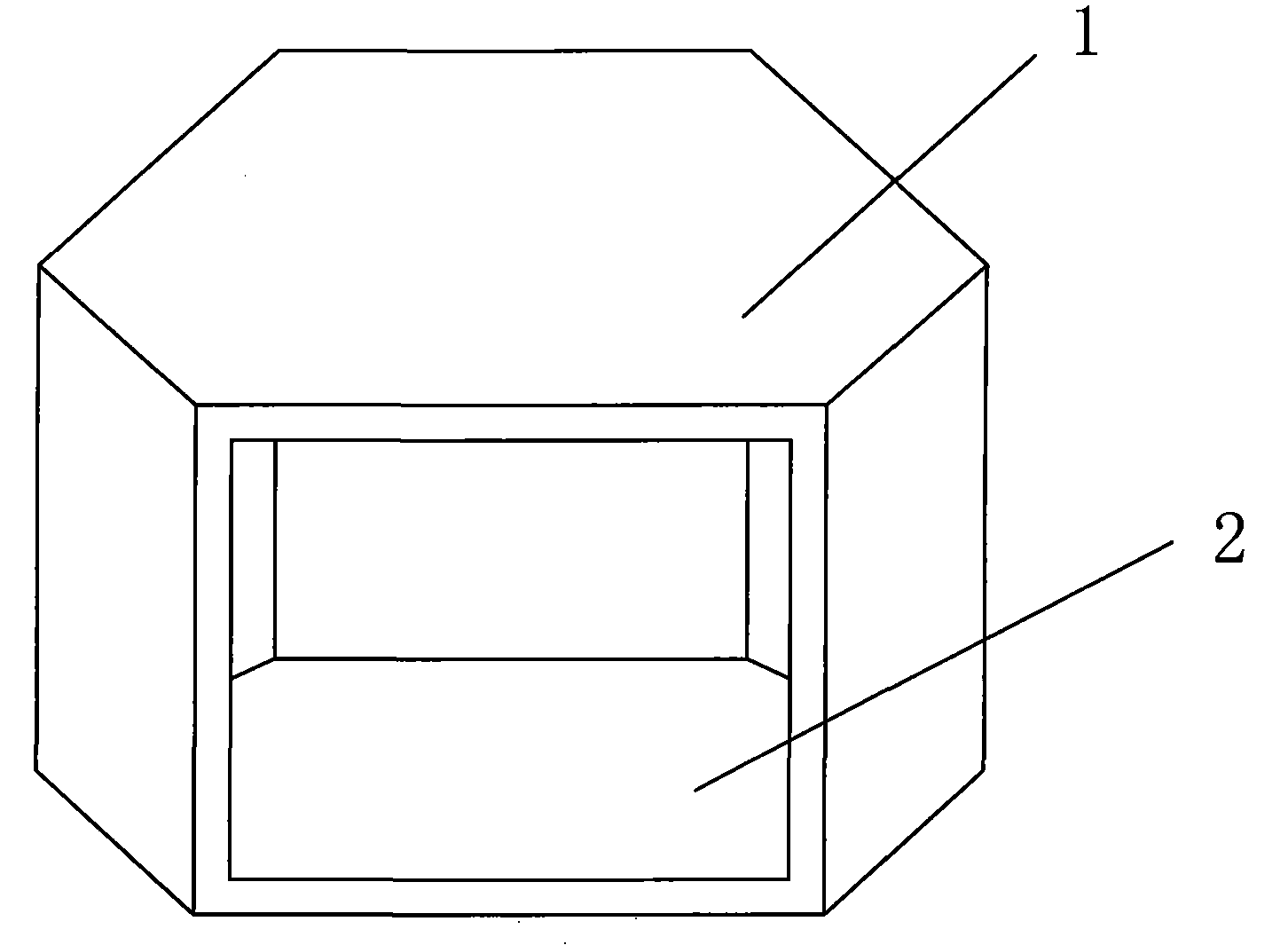

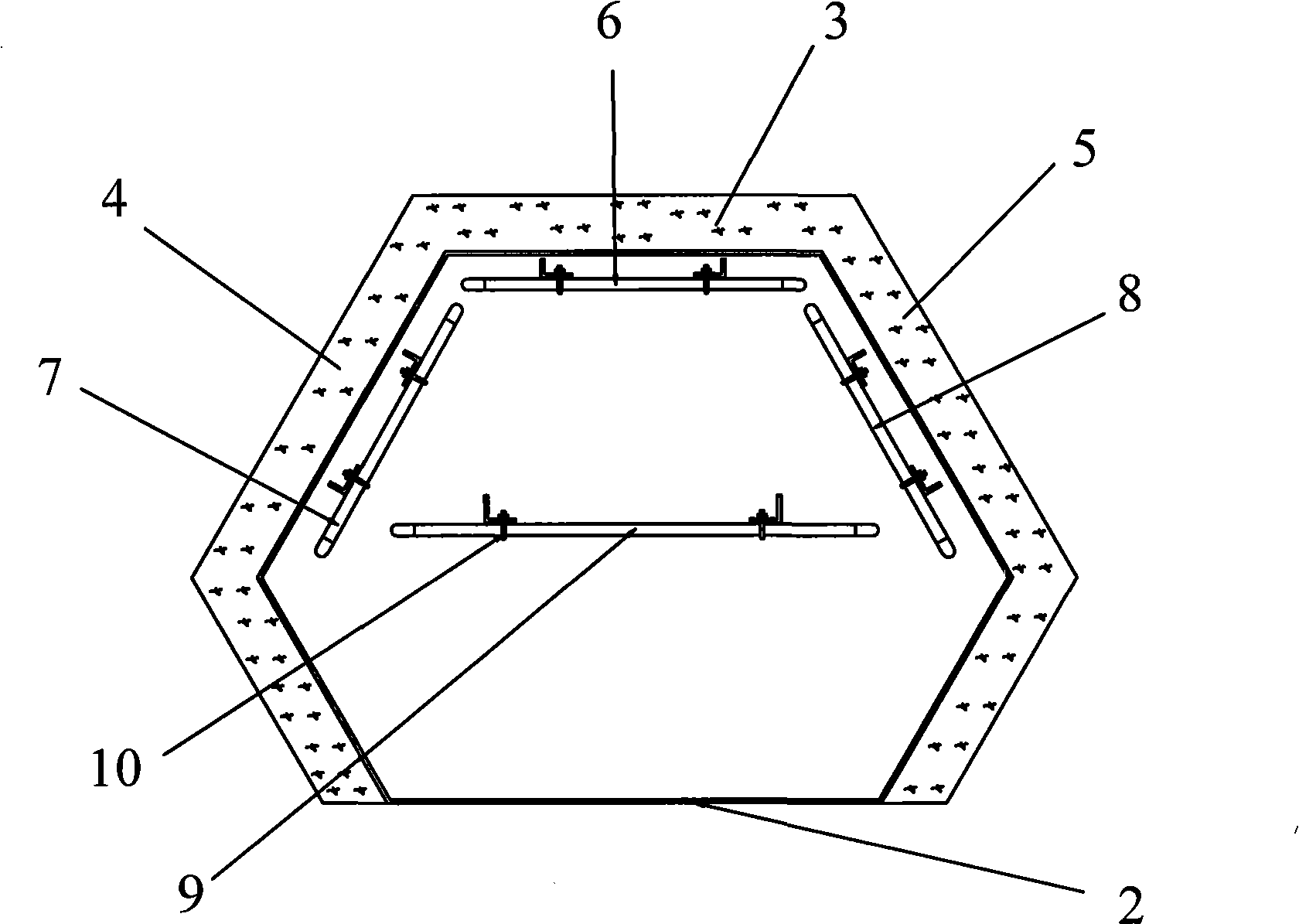

The invention relates to the field of tower type solar heat power generation research, discloses a simulation device for a solar cavity type heat absorber, and is applicable to a simulation performance test of a cavity type heat absorber in the tower type solar heat power generation system. The simulation device comprises a drum and a hexagonal prism shaped heat absorbing cavity, wherein a side surface of the heat absorbing cavity is provided with a daylight opening; a dead backside wall, a left backside wall and a right backside wall of the heat absorbing cavity are arranged opposite to the daylight opening; a dead backside boiling tube, a left backside boiling tube and a right backside boiling tube are respectively arranged close to the dead backside wall, the left backside wall and theright backside wall; a superheat tube is arranged between the daylight opening and the dead backside wall; and the dead backside boiling tube, the left backside boiling tube, the right backside boiling tube and the superheat tube are respectively communicated with the drum. The simulation device is characterized in that the dead backside boiling tube, the left backside boiling tube, the right backside boiling tube and the superheat tube are made of stainless steel pipe coils which are directly heated by a power supply.

Description

A simulation device of a solar cavity heat absorber technical field The invention relates to the research field of tower-type solar thermal power generation, in particular to a simulation device of a solar cavity heat absorber, which is suitable for the simulation test of the performance of the cavity type heat absorber in a tower-type solar thermal power generation system. Background technique Solar thermal power generation technology uses an optical system to gather solar radiation energy to heat the working medium to generate steam, which drives a steam turbine generator set to generate electricity. According to different concentrating methods, solar thermal power generation can be divided into: tower solar thermal power generation, trough solar thermal power generation and dish solar thermal power generation. At present, trough solar thermal power generation has been commercialized, while tower solar thermal power generation and dish solar thermal power generation are ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M99/00

Inventor 郭烈锦魏进家张西民王跃社方嘉宾

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com