Sedan gear-box axle piece cold finish-forging formation method and die

A technology of gearbox and cold precision forging, applied in manufacturing tools, engine components, forging/pressing/hammer devices, etc., can solve the problems of insufficient strength, low material utilization, low surface quality, etc., and achieve long service life , good mechanical properties, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

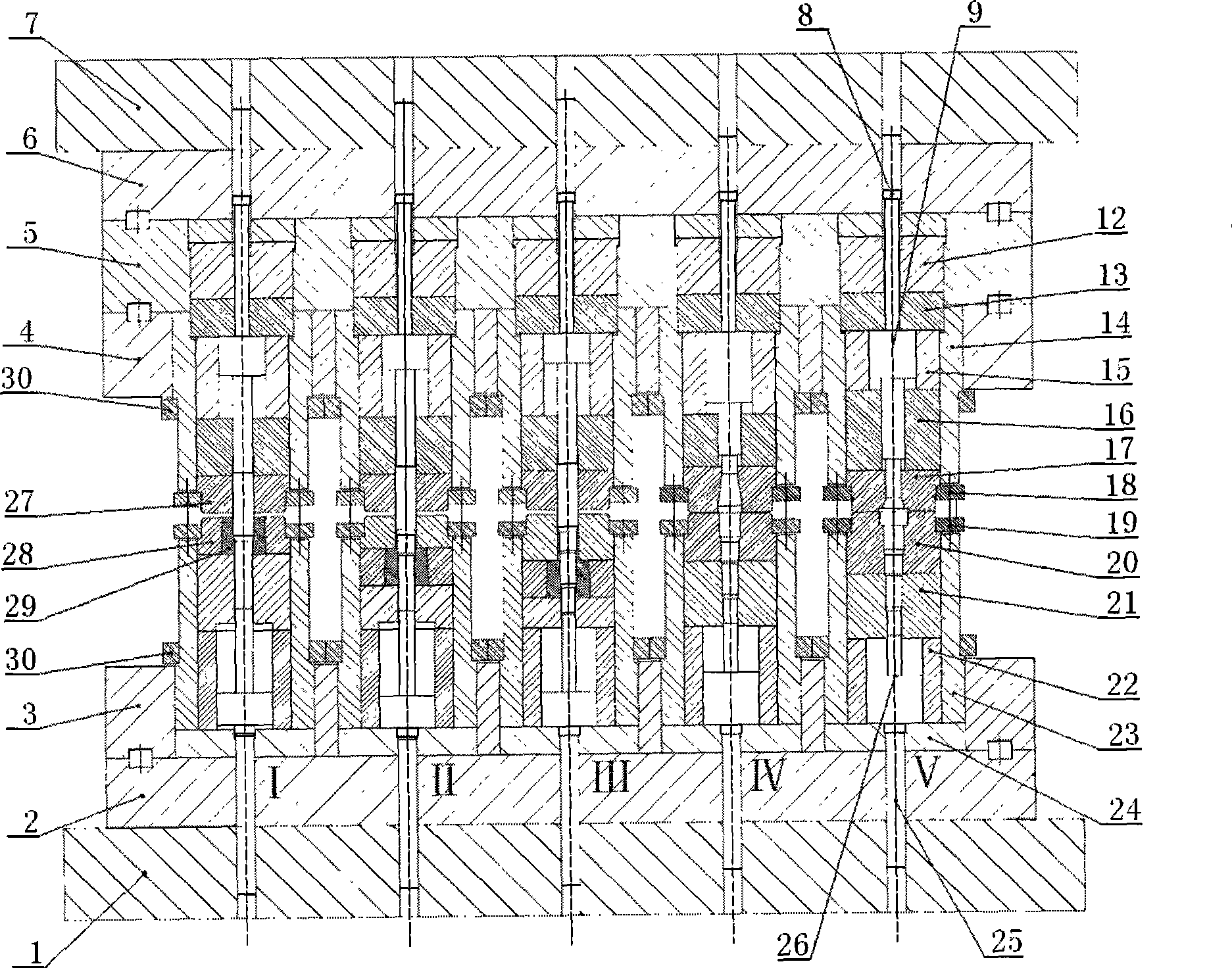

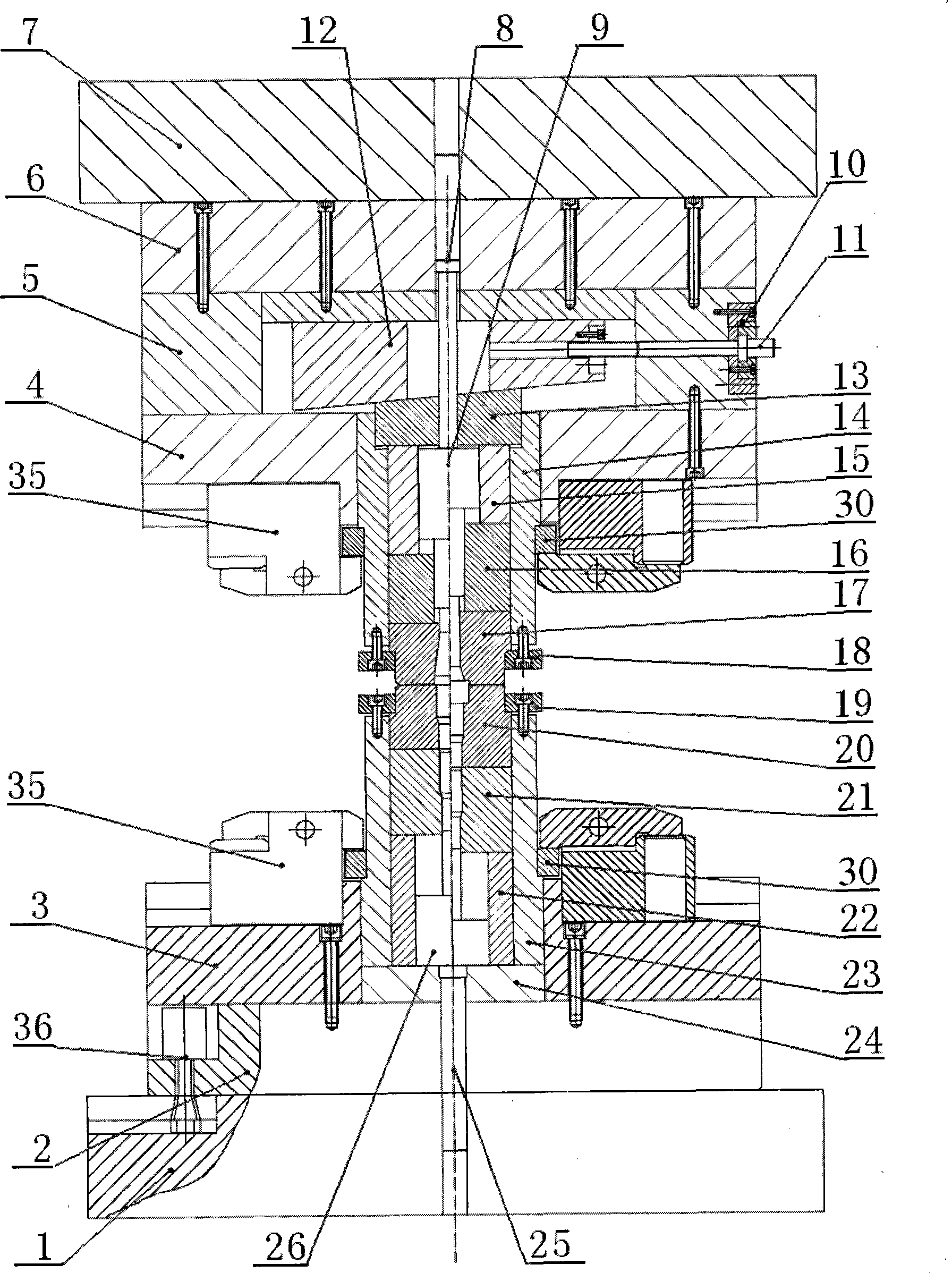

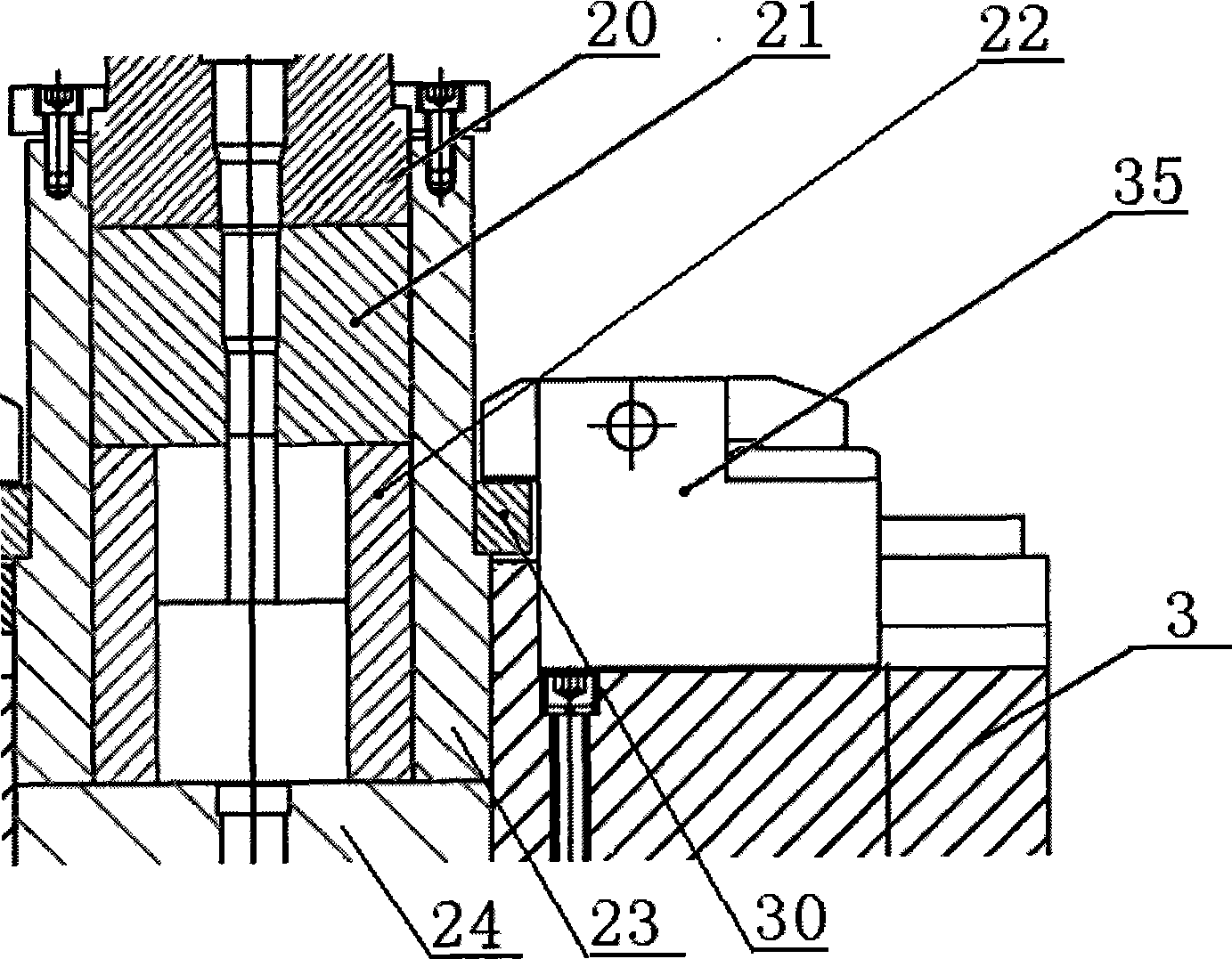

[0049] Such as figure 1 , figure 2 As shown, an embodiment of the present invention is used for the production of the car gearbox output shaft, including upper and lower mold bases, upper and lower ejectors, mold units and fastening devices thereof;

[0050] figure 2 It is the right side view of the step section of the cold precision forging die on the symmetrical plane of the fourth pair of die unit IV and the fifth pair of die unit V; the left side of the central axis is the section view of the fourth pair of die unit IV, and the right side is the fifth pair of dies Sectional view of unit V;

[0051] The upper mold base is composed of an upper base plate 6, an upper template backing plate 5, a panel 10, an adjusting screw 11, a wedge 12, and an upper template 4; the upper base plate 6, the upper template backing plate 5, and the upper template 4 are connected by screws in turn, Backing plate 5 has five wedges 12 built in, a panel 10 with a scale is installed on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com