Injection molding device feeding-port cooler

A cooler and injection molding machine technology, which is applied in the field of injection molding machine processing parts, can solve the problems of high working temperature of the feeding barrel affecting production efficiency, etc., and achieve the effects of improving particle blockage, improving performance and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

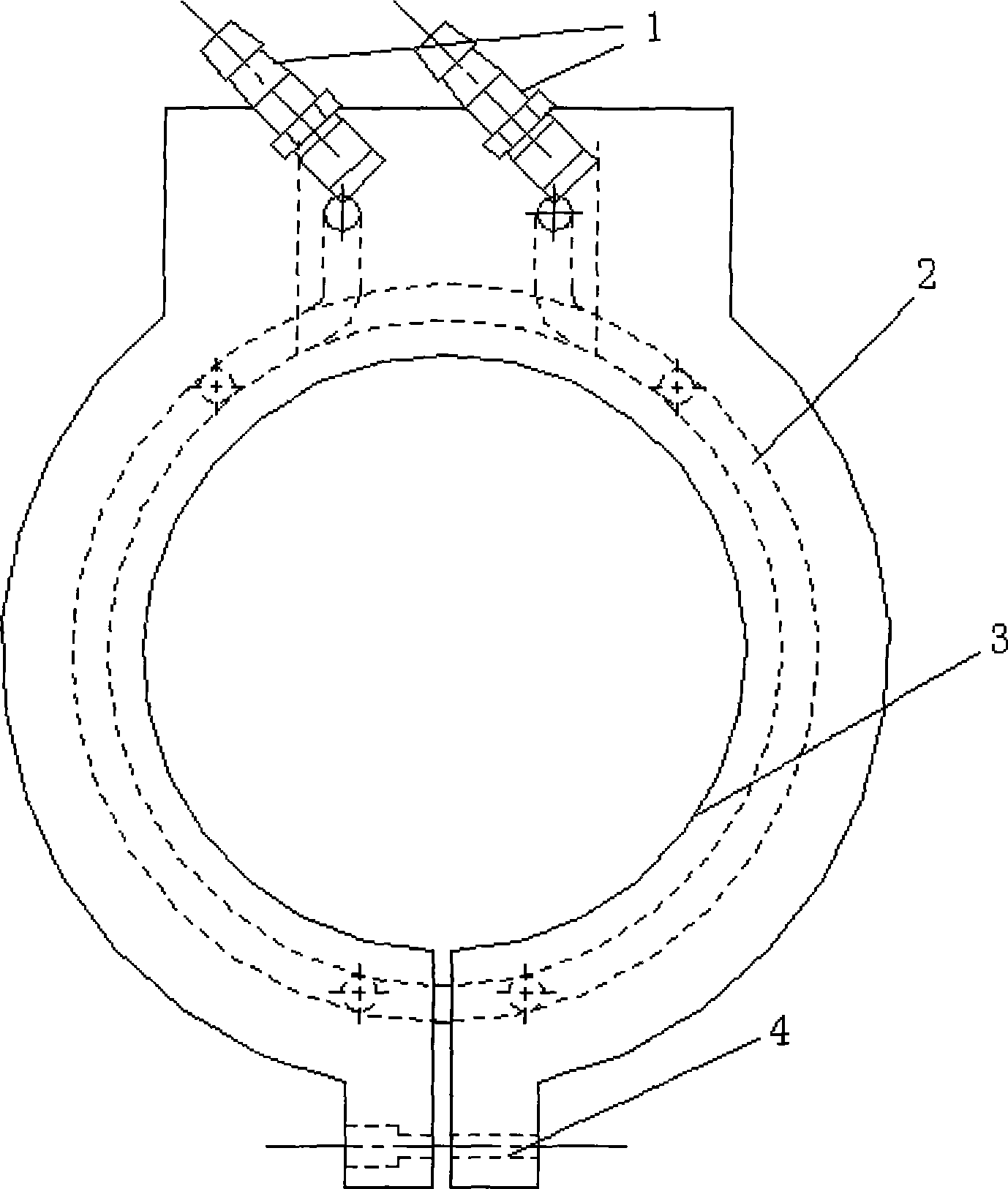

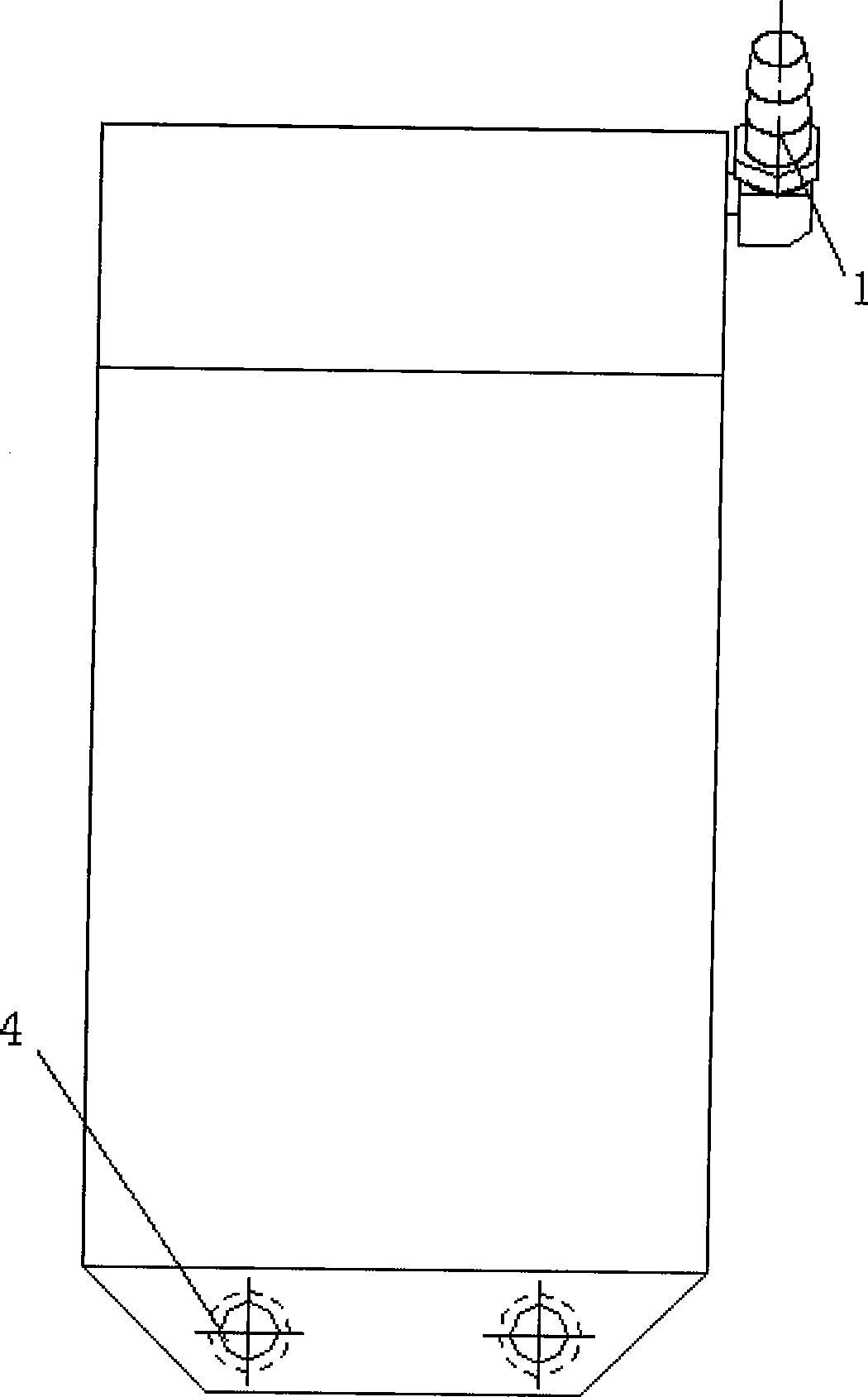

[0014] A cooler for the discharge port of an injection molding machine, which is composed of a heat exchange shell 3 and a cooling pipe 2 installed in the heat exchange shell. The cooling pipe 2 is a stretchable stainless steel bellows, and the inner wall of the heat exchange shell 3 is made of material grade Made of A360 aluminum alloy, the heat exchange shell 3 is an open circular ring with fastening screw holes 4 and a gap width of 1-5 cm. The cooling pipe 2 is equipped with a water inlet and outlet 1 .

[0015] After the injection molding head of the heating screw enters, tighten it with screws through the fastening screw hole 4 at the opening, and hold the heating screw, so that the heating screw quickly dissipates heat through the inner wall made of heat-conducting material to achieve cooling; The water is circulated and cooled, and it can work under the pressure of 5Pa per minute and the water flow rate of 80mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com