Production process of conveyer belt for running trainer

A production process and conveyor belt technology, applied in applications, belts, household appliances, etc., can solve the problems of poor product fastness, easy sticking of products, product failure, etc., and achieve significant economic value, good air tightness, Excellent surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

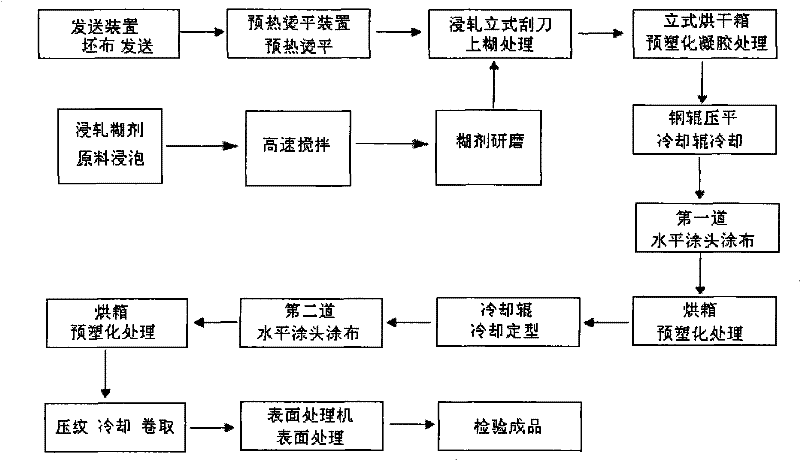

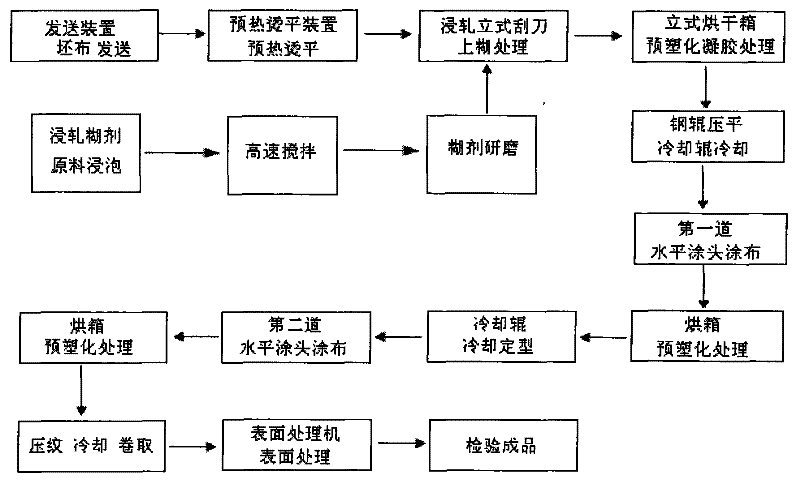

Image

Examples

Embodiment 1

[0041] The specific steps of the process are:

[0042] 1) Sending: the gray cloth is placed on the sending device for sending, and one end of the core tube on the sending device is equipped with a magnetic brake device for adjusting the tension;

[0043]2) Preheating and ironing: the gray cloth is preheated and ironed through the preheating and ironing device on the sending device; this step is a set of heating steel rollers, and the temperature is controlled at 80 degrees;

[0044] 3) Paste on the padding vertical scraper: dip the preheated gray cloth into the paste so that the warp and weft of the cloth are filled with paste, and then pass through a pair of rolls to roll off the excess paste, vertically Scrape the excess paste with a scraper, adjust the paste amount of each cloth by adjusting the viscosity of the paste, the pressure of the roll and the gap between the scrapers to 300g / m 2 ;

[0045] 4) Pre-plasticized gel treatment: drying the padded and pasted gray cloth ...

Embodiment 2

[0059] The specific steps of the process are:

[0060] 1) Sending: the gray cloth is placed on the sending device for sending, and one end of the core tube on the sending device is equipped with a magnetic brake device for adjusting the tension;

[0061] 2) Preheating and ironing: the gray cloth is preheated and ironed through the preheating and ironing device on the sending device; this step is a set of heating steel rollers, and the temperature is controlled at 120 degrees;

[0062] 3) Paste on the padding vertical scraper: dip the preheated gray cloth into the paste so that the warp and weft of the cloth are filled with paste, and then pass through a pair of rolls to roll off the excess paste, vertically Use a scraper to scrape off the excess paste, and adjust the amount of paste on each cloth by adjusting the viscosity of the paste, the pressure of the roll and the gap between the scrapers to 500g / m 2

[0063] 4) Pre-plasticized gel treatment: drying the padded and paste...

Embodiment 3

[0077] The specific steps of the process are:

[0078] 1) Sending: the gray cloth is placed on the sending device for sending, and one end of the core tube on the sending device is equipped with a magnetic brake device for adjusting the tension;

[0079] 2) Preheating and ironing: the gray cloth is preheated and ironed through the preheating and ironing device on the sending device; this step is a set of heating steel rollers, and the temperature is controlled at 100 degrees;

[0080] 3) Paste on the padding vertical scraper: dip the preheated gray cloth into the paste so that the warp and weft of the cloth are filled with paste, and then pass through a pair of rolls to roll off the excess paste, vertically Use a scraper to scrape off the excess paste, and adjust the paste amount of each cloth to 400g / m by adjusting the viscosity of the paste, the pressure of the roll and the gap between the scrapers 2 ;

[0081] 4) Pre-plasticized gel treatment: Dry the gray cloth that has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com