Hydrogen gas recovering device of intermediate frequency furnace

A recovery device and intermediate frequency furnace technology, applied in the direction of hydrogen separation, etc., can solve the problems of increasing production costs, wasting hydrogen, increasing production safety hazards, etc., and achieve the effects of saving production costs, reducing production costs, and eliminating production safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

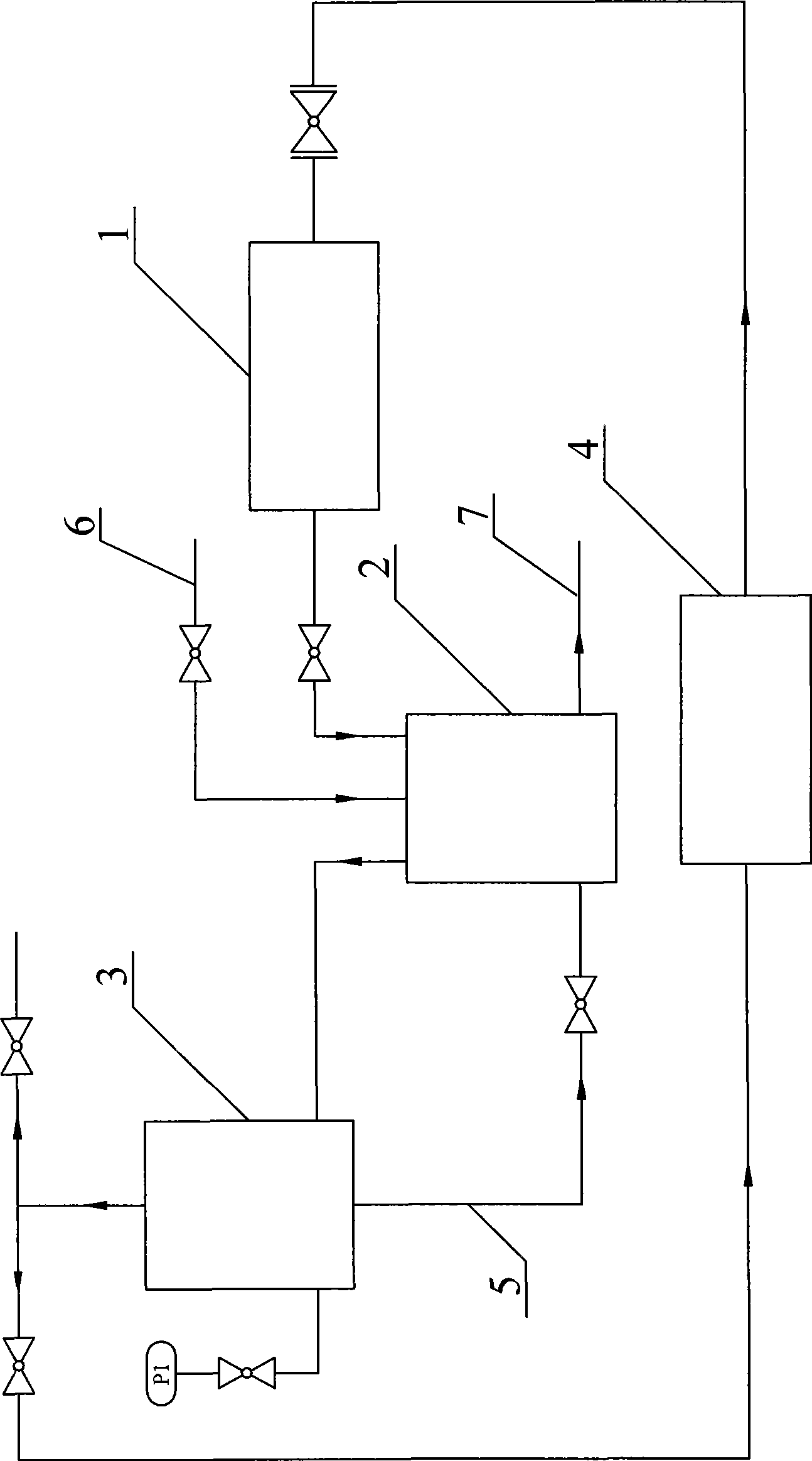

[0010] Such as figure 1 as shown,

[0011] The present invention consists of an intermediate frequency furnace 1, a water seal 2 for isolating the hydrogen discharged from the intermediate frequency furnace from the outside air, a gas-water separator 3 for removing moisture in the hydrogen discharged from the water seal, and a hydrogen recovery treatment system 4 It consists of an intermediate frequency furnace 1, a water seal 2, a gas-water separator 3, and a hydrogen recovery treatment system 4 which are sequentially connected through pipelines.

[0012] In addition, the gas-water separator 3 and the water seal 2 are connected through a return pipe 5 . The upper end of the water seal 2 is connected with the water supply pipe 6, and the lower end is also connected with the drain pipe 7.

[0013] The hydrogen gas discharged from the intermediate frequency furnace 1 enters the water seal 2, and the hydrogen gas is cooled by the water seal 2 and then input into the gas-water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com