Electrorheological liquid preparation method for core-shell particle/composite base liquid

An electrorheological fluid and composite matrix technology, applied in the field of material science and engineering, can solve the problems of easy precipitation, poor anti-settling resistance of electro-rheological fluid, and large particle ratio, and achieve the effect of improving electro-rheological strength and improving anti-settling property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Select nickel particles with an average particle size of 40 nanometers;

[0017] 2. Put the particles into an aqueous solution of 8mol / l NaOH (8mol / l) for ultrasonic stirring, then wash with water, magnetically separate the particles, and add tetrabutyl titanate to absolute ethanol in a volume ratio of 1: 1 solution, ultrasonic stirring, magnetic separation of particles;

[0018] 3. Add a mixed solution containing urea, deionized water, and absolute ethanol to the particles, stir ultrasonically, wash with water, separate the particles magnetically, and dry the particles at 120°C. The volume ratio of the components of the mixed solution is urea : deionized water: absolute ethanol = 4:1:10;

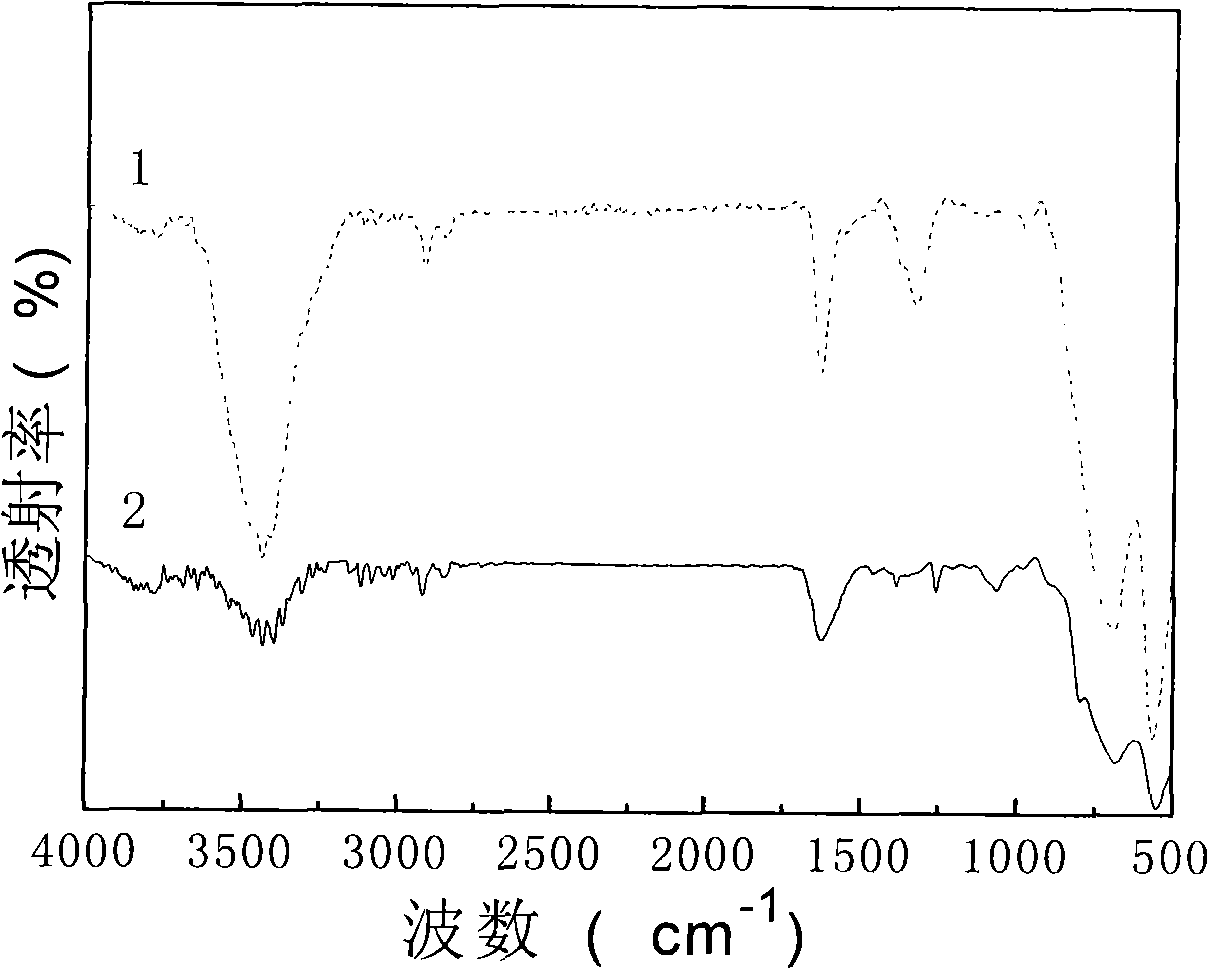

[0019] 4. Repeat steps 2 to 3 twice for the particles treated in step 3 to obtain nano-core-shell particles with nano-nickel as the core and titanium dioxide and organic polar molecules as the coating layer; the infrared spectrum of the core-shell particles is as follows: figure...

Embodiment 2

[0023] 1~2. With step 1~2 in the embodiment one;

[0024] 3. Add a mixed solution containing triethanolamine, deionized water, and absolute ethanol to the particles obtained in step 2. The volume ratio of each component of the mixed solution is triethanolamine: deionized water: absolute ethanol=4:1:10 , ultrasonically stirred, washed with water, and magnetically separated particles;

[0025] 4-5. Same as steps 4-5 in Example 1.

[0026] The infrared spectra of the prepared core-shell particles are as follows: figure 1 Shown in curve 2.

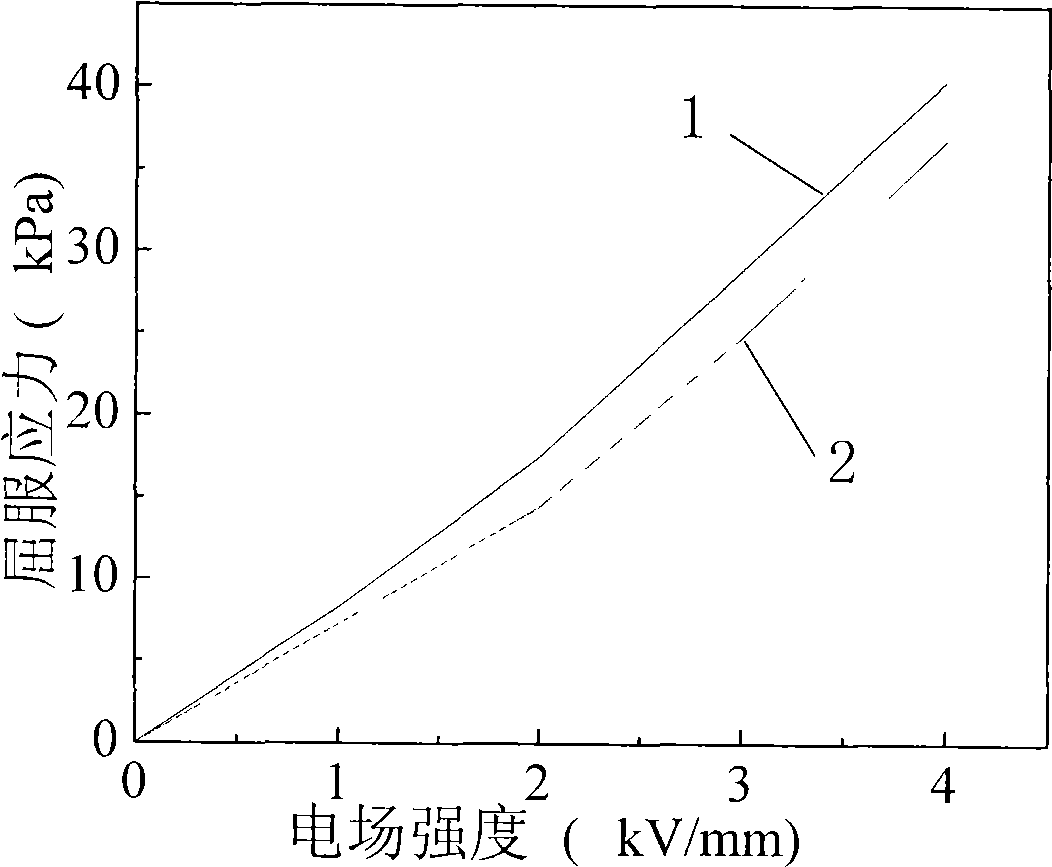

[0027] The rheological properties are measured with NXS-11 plate-plate viscometer, the relationship between the yield strength of the electrorheological fluid and the electric field intensity is shown in the attached figure 2 Shown in curve 2. After being placed for three months, the anti-sedimentation rate of the electrorheological fluid was measured to be 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com