Modified heavy calcium carbonate special for paint and preparation method and device thereof

A technology of heavy calcium carbonate and coatings, applied in the field of paints and coatings, which can solve the problems of performance degradation of paints and coatings, defects in the two-phase interface, weak matrix bonding force, etc., and achieve the effects of reducing oil absorption value, increasing dispersibility, and environmental protection of production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

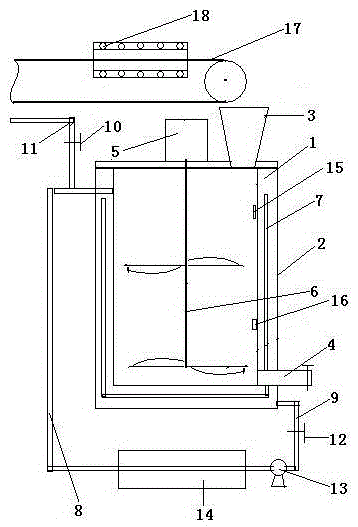

Image

Examples

Embodiment 1

[0021] Embodiment 1: This special modified heavy calcium carbonate for paint coatings is prepared by mixing organic raw materials and inorganic raw materials. Its oil absorption value is 20g oil / 100g heavy calcium carbonate. The organic raw materials and inorganic raw materials The weight and number ratio is 6-8:1000; according to the weight and number ratio, the inorganic raw materials include: heavy calcium carbonate 95-100, aluminum nitride 0.3-0.5, α-alumina 0.4-0.6, nano-dioxide Silicon (VK-SP30) 1-2, kaolin 1-2 and diatomite 1-2, the particle size of the above raw materials is less than or equal to 800 mesh;

[0022] The organic raw material is polyoxyethylene oleate.

Embodiment 2

[0023] Embodiment two: this special modified heavy calcium carbonate for paints and coatings is prepared by mixing organic raw materials and inorganic raw materials, and its oil absorption value is 19g oil / 100g heavy calcium carbonate, organic raw materials and inorganic raw materials The weight and number ratio is 6-8:1000; By weight and number ratio, in addition to including in the embodiment one in the inorganic raw material, also add mica 1-2;

[0024] The organic raw materials are polyoxyethylene oleate and polyethylene wax, and the weight fractions of the above two organic raw materials are equal.

Embodiment 3

[0025] Embodiment three: this special modified heavy calcium carbonate for paint coatings is prepared by mixing organic raw materials and inorganic raw materials, and its oil absorption value is 18g oil / 100g heavy calcium carbonate, organic raw materials and inorganic raw materials The weight and number ratio is 6-8:1000; According to the weight and number ratio, in addition to including the embodiment one in the inorganic raw materials, silicon carbide 1-2 is also added;

[0026] The organic raw materials include: polyoxyethylene oleate, polyethylene wax and styrene, and the weight fractions of the three organic raw materials are equal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com