Grinder hammerhead and manufacturing method thereof

A manufacturing method and technology of a crusher, applied in the direction of grain processing, etc., can solve the problems of short service life, easy to break and fall off, and the hammer head cannot have both toughness and wear resistance, so as to improve the service life, not easy to break and fall off, and stable. The effect of improving sex and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture Embodiment 1

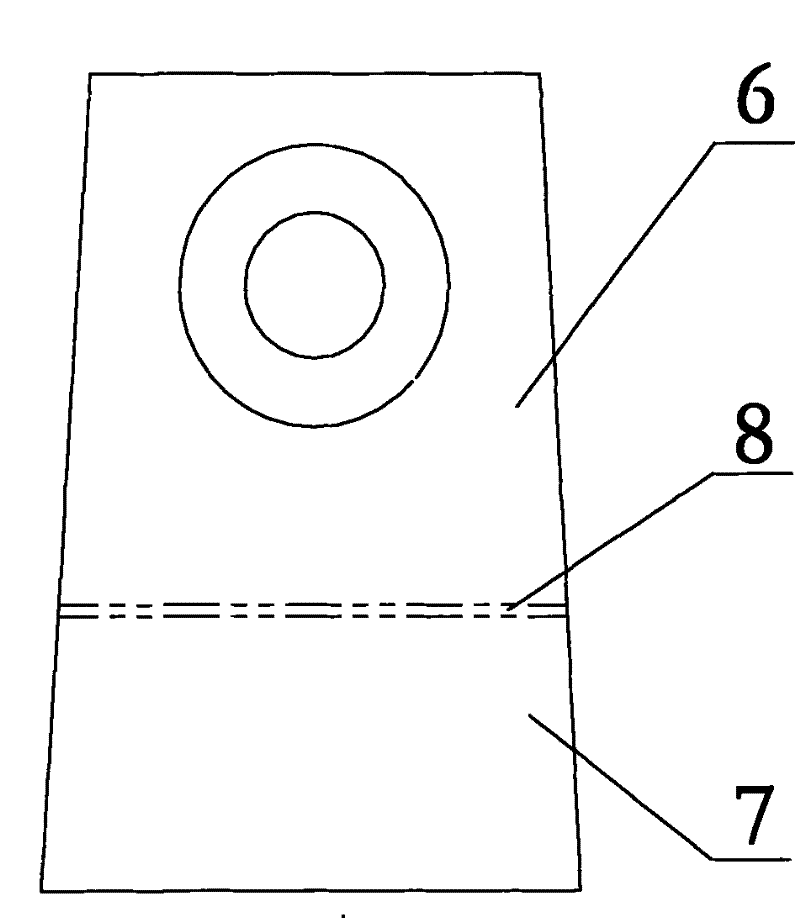

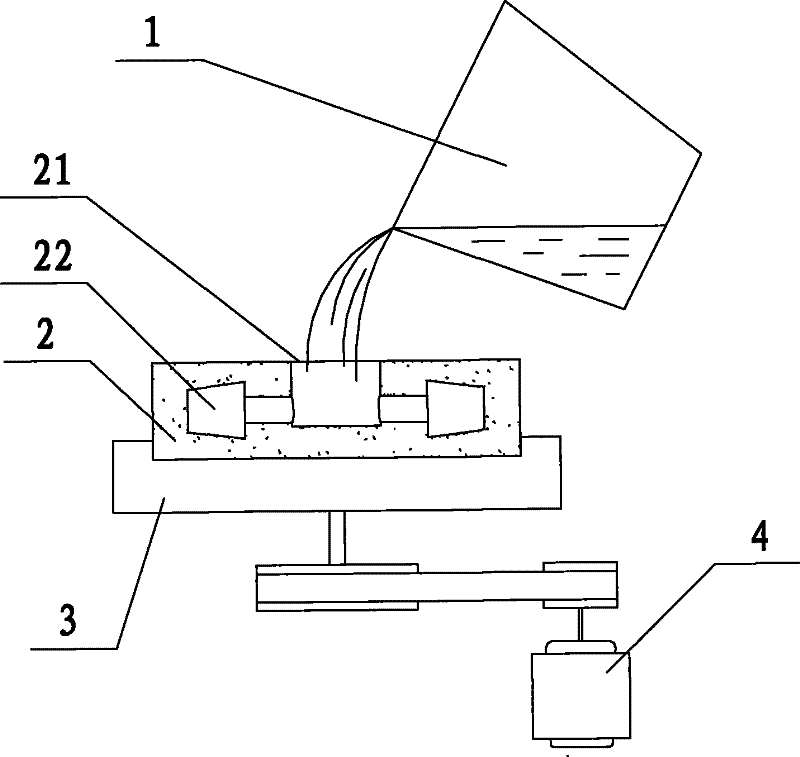

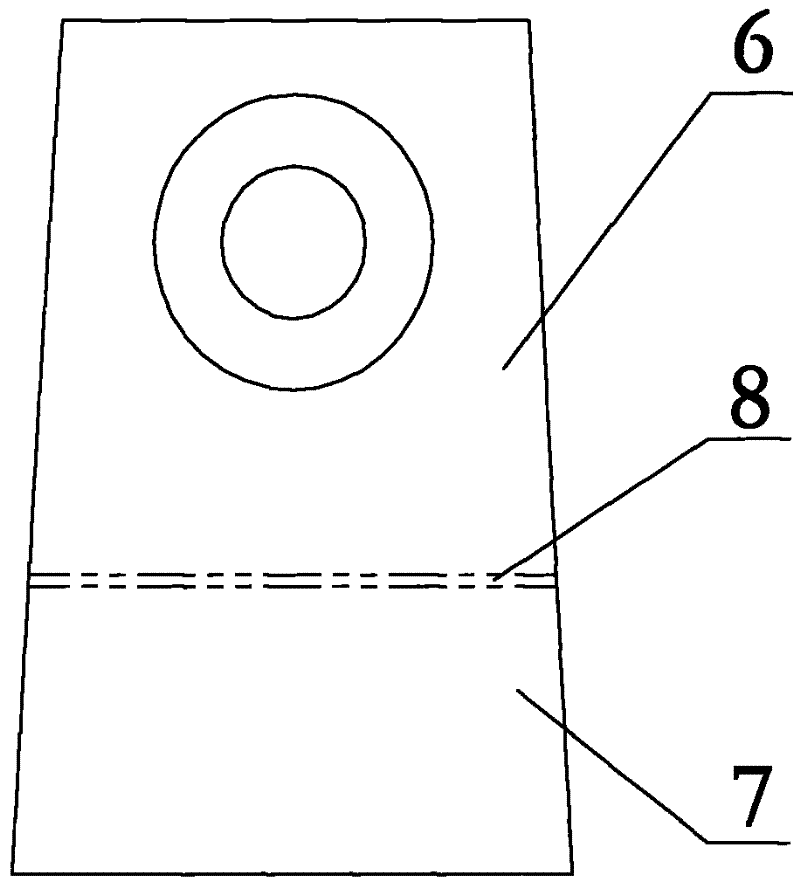

[0045] a. Smelting 30kg of high-toughness carbon steel molten metal according to the formula of Example 1 in an intermediate frequency electric furnace, the furnace temperature is 1600°C, pouring it into the hammerhead cavity 22 from the pouring port 21 of the sand mold 2 at 0.3kg / s by the pouring device 1, The pouring temperature is 1550, and the speed of sand mold 2 is 300 rpm;

[0046] b. Melting 31 kg of wear-resistant alloy cast iron of the formula of Example 11 in an intermediate frequency electric furnace, the temperature of the furnace is 1500 ° C, and the pouring device 1 injects it from the sprue 21 of the sand mold 2 into the hammerhead cavity 22 at 0.4 kg / s. The pouring temperature is 1450°C, and the speed of sand mold 2 is 200 rpm;

[0047] c. After pouring is completed, keep the speed of sand mold 2 at 100 rpm, rotate for 15 minutes, stop and cool;

[0048] d. Raise the temperature to 920°C and keep it warm for 1 hour. After it comes out of the furnace, carry ou...

manufacture Embodiment 2

[0050] a. Smelting 40kg of high-toughness carbon steel molten metal of the formula of Example 4 in an intermediate frequency electric furnace, the furnace temperature is 1700°C, pouring it from the pouring port 21 of the sand mold 2 into the hammerhead cavity 22 by the pouring device 1 at 0.4kg / s, The pouring temperature is 1620, and the speed of sand mold 2 is 400 rpm;

[0051] b. smelting 28kg of wear-resistant alloy cast iron of the formula of Example 14 in an intermediate frequency electric furnace, the temperature of the furnace is 1600°C, and pouring it from the sprue 21 of the sand mold 2 into the hammerhead cavity 22 by the pouring device 1 at 0.5kg / s, The pouring temperature is 1550°C, and the speed of sand mold 2 is 300 rpm;

[0052] c. After pouring is completed, keep the speed of sand mold 2 at 250 rpm, rotate for 25 minutes, stop and cool;

[0053] d. Raise the temperature to 920°C and keep it warm for 2 hours, then carry out air-cooling treatment after being rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com