Printing decoration method for polyester fibre/acetate blended high-grade resist printing face fabric

A printing method and polyester technology, applied in the field of printing technology of polyester/differential fiber blended fabrics, can solve the problems of difficulty in removing disperse dyes, affecting the vividness of color, monotonous color varieties, etc., and achieve good printing fastness, bright color, Cool and comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

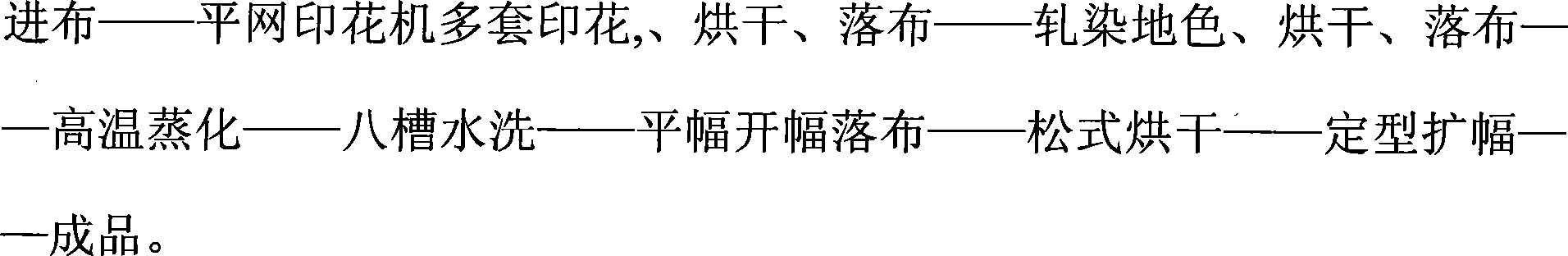

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with specific examples, but the present invention is not limited to the specific examples.

[0016] (1) Process test before production:

[0017] 1. Selection of disperse dyes for printing and repellent (ground color) disperse dyes:

[0018] Table I

[0019] Disperse dyes for printing Resistant (ground color) disperse dyes Big Love Nix Red AM—BN

Big Love Nix Blue S—BG

Big Love Nix Yellow 7GL Kayalon Blue BD—S

Kayalon Red TL—SF

Kayalong Yellow BRL—S

Kayalon Blue 2RSF

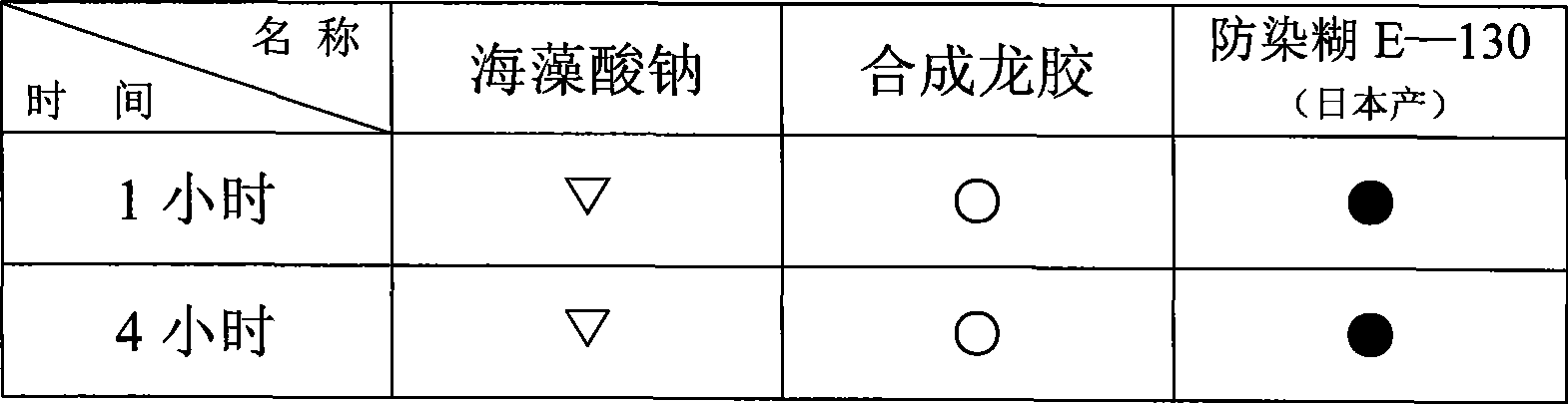

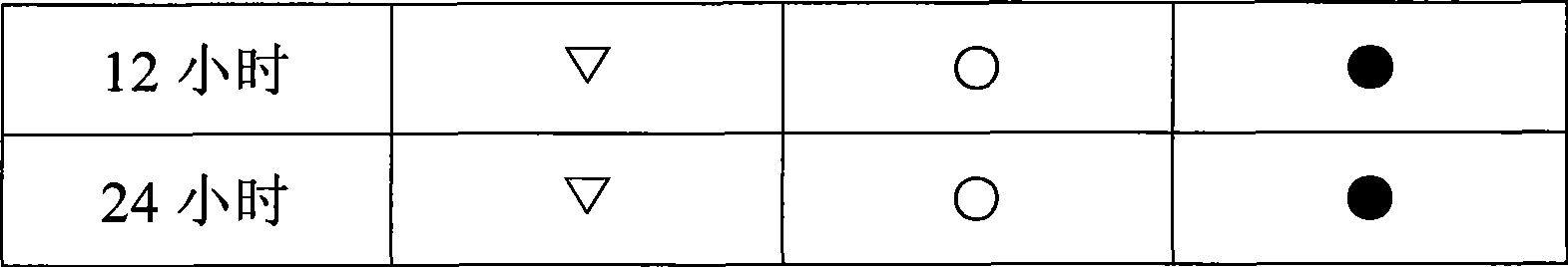

[0020] 2. Paste selection for anti-dyeing agent in the color paste of disperse dyes: Table 2

[0021]

[0022]

[0023] ●Good ○Fair ◇Average Difference

[0024] 3. Paste selection for anti-dyeing agent in the color paste of pearlescent pigments:

[0025] ①#Printing thickener REDUCER conc 400 / sodium alginate

[0026] ②#Printing thickener REDUCER conc 400 / synthetic dragon glue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com