Optical lens for ultraviolet laser interference photolithography straight-writing system

An ultraviolet laser and optical lens technology, applied in microlithography exposure equipment, optics, optical components, etc., can solve the problem of impossible to make sub-micron structure patterns, and achieve the goal of reducing aberration, improving imaging quality, and reducing the number of lenses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

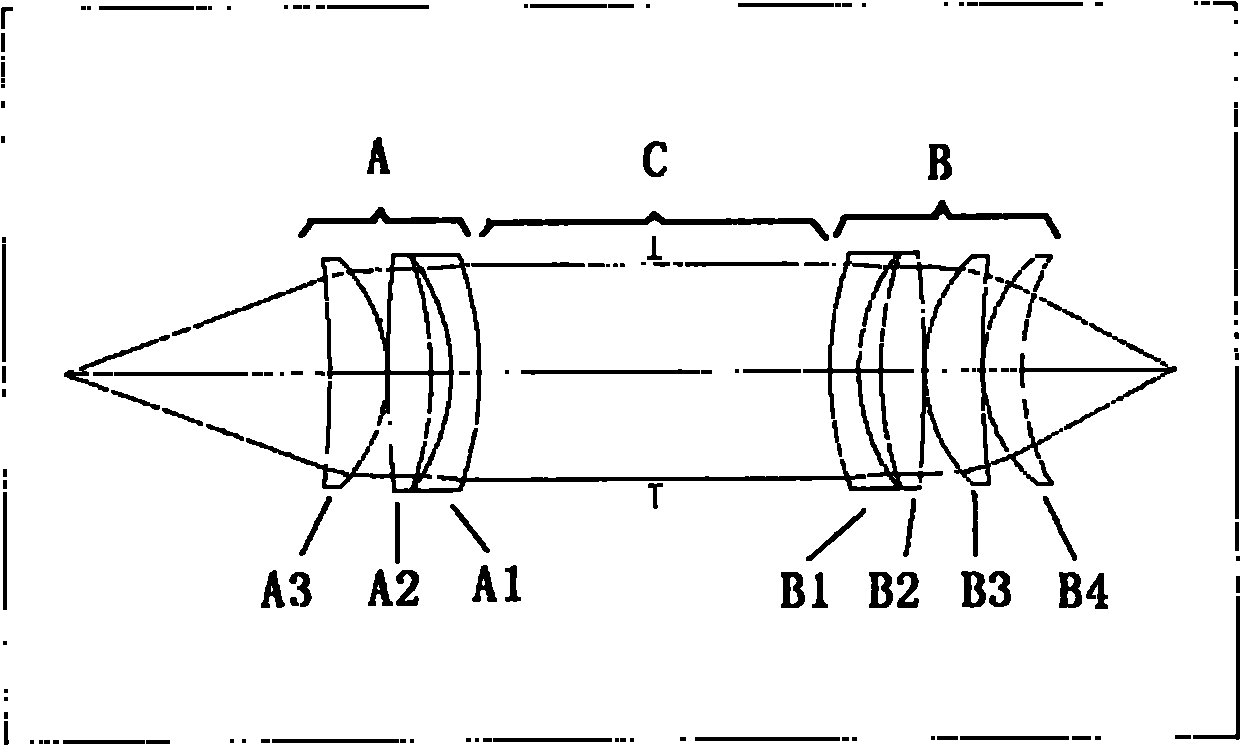

[0033] Such as figure 2 As shown, the ultraviolet interference lens is composed of two groups of seven lenses consisting of object-side lens group A and image-side lens group B. The two groups of lenses form a bi-telecentric optical system. The distance between the two groups of lenses can be changed to achieve focusing. Features. Group A lens is composed of three lenses A3, A2, A1, and group B lens is composed of four lenses B1, B2, B3, B4. The optical materials are all fused silica (SILICA) with high transmittance in the ultraviolet band. The propagation directions are A3, A2, A1, B1, B2, B3, and B4 in sequence; among them, A1, B1 are meniscus concave lenses, A2, B2 are biconvex lenses, and A3, B3, B4 are meniscus convex lenses.

[0034] The structural data of the interference lens are as follows (unit: mm):

[0035] serial number

spacing

Material

Object surface

36.968

Air

1

-145.55

8

Fu...

Embodiment 2

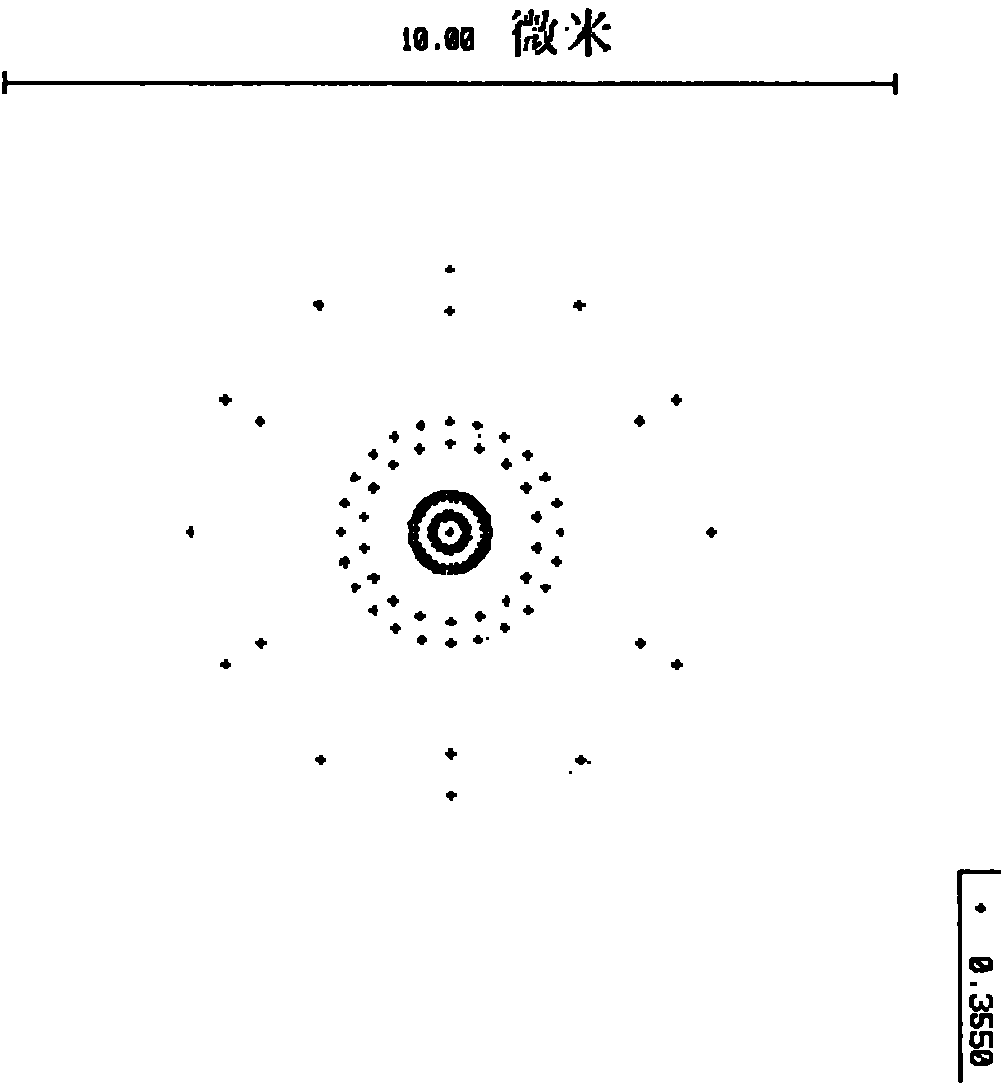

[0042] attached Figure 10 It is the structure diagram of the second embodiment of the ultraviolet interference lens of the present invention, and at a wavelength of 355nm, the object-side numerical aperture reaches 0.55.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com