SOC chip of oiling machine control system

A control system and fuel dispenser technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of high power consumption, low utilization of internal resources, high cost of CPLD or FPGA, and achieve power consumption Value reduction, high utilization of internal resources, and the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

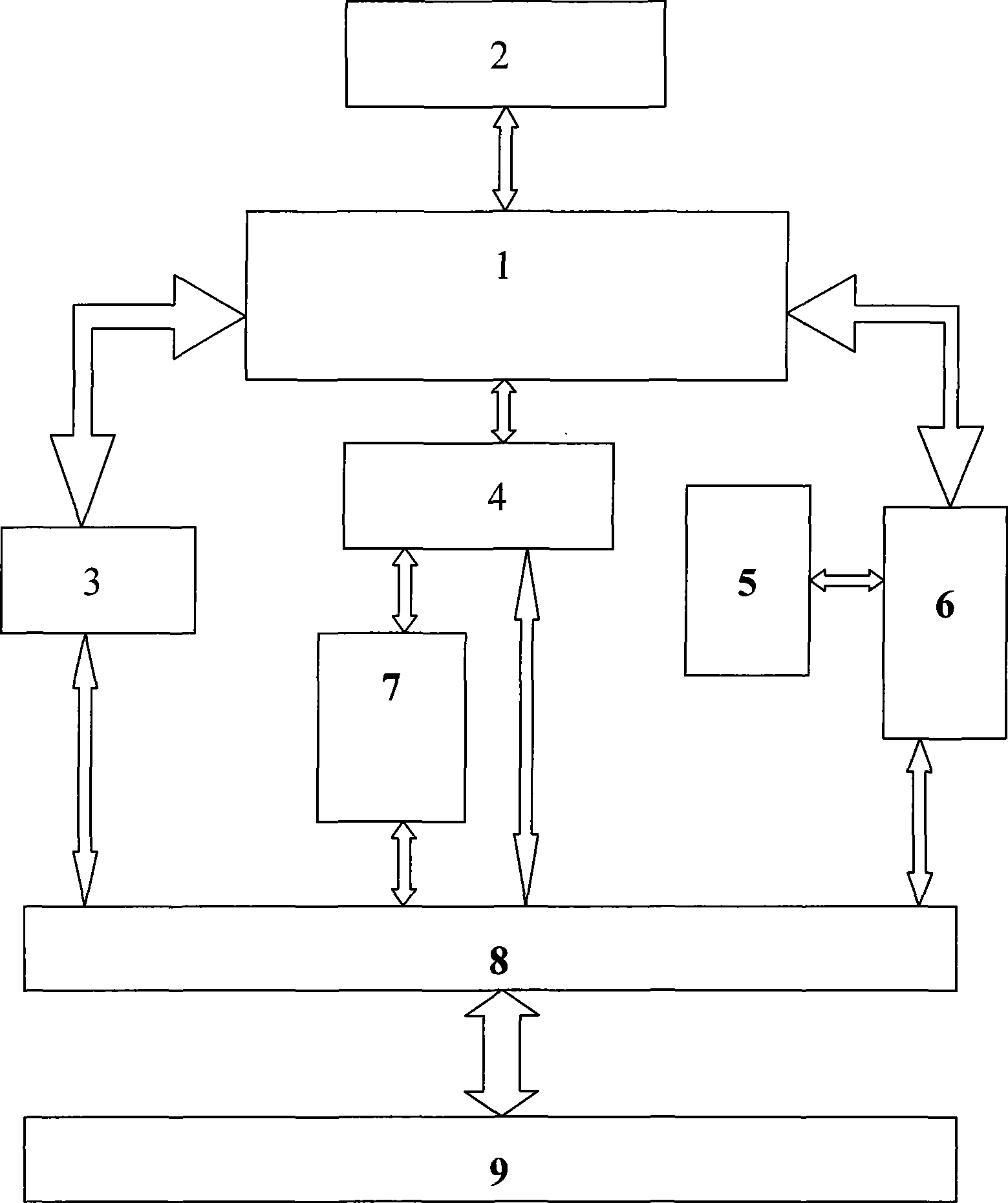

[0013] Examples of the present invention figure 1 As shown, it consists of CPU processing module 1, data transmission module 4, CAN bus control module 3, RAM data storage module 2, ROM program storage module 5, online program burning module 6, Viterbi encoding and decoding module 7, JTAG testing module 8, IO pin module 9 is formed; It is characterized in that, data transmission module 1, CAN bus control module 3, RAM data storage module 2, online program burning module 6 are connected with CPU processing module 1 respectively, ROM program storage module 5 is connected with online program The burning module 6 is connected, and the Viterbi codec module 7 is connected with the data transmission module 4. At the same time, the data transmission module 4, the CAN bus control module 3, the online program burning module 6, and the Viterbi codec module 7 are respectively connected with the JTAG test module 8 , the JTAG test module 8 is connected to the IO pin module 9 .

[0014] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com