Kick type temperature controller

A technology of sudden jump type thermostat and terminal, applied in the direction of thermal switch parts, etc., to achieve the effect of increasing the cross-sectional area of electricity, improving performance, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

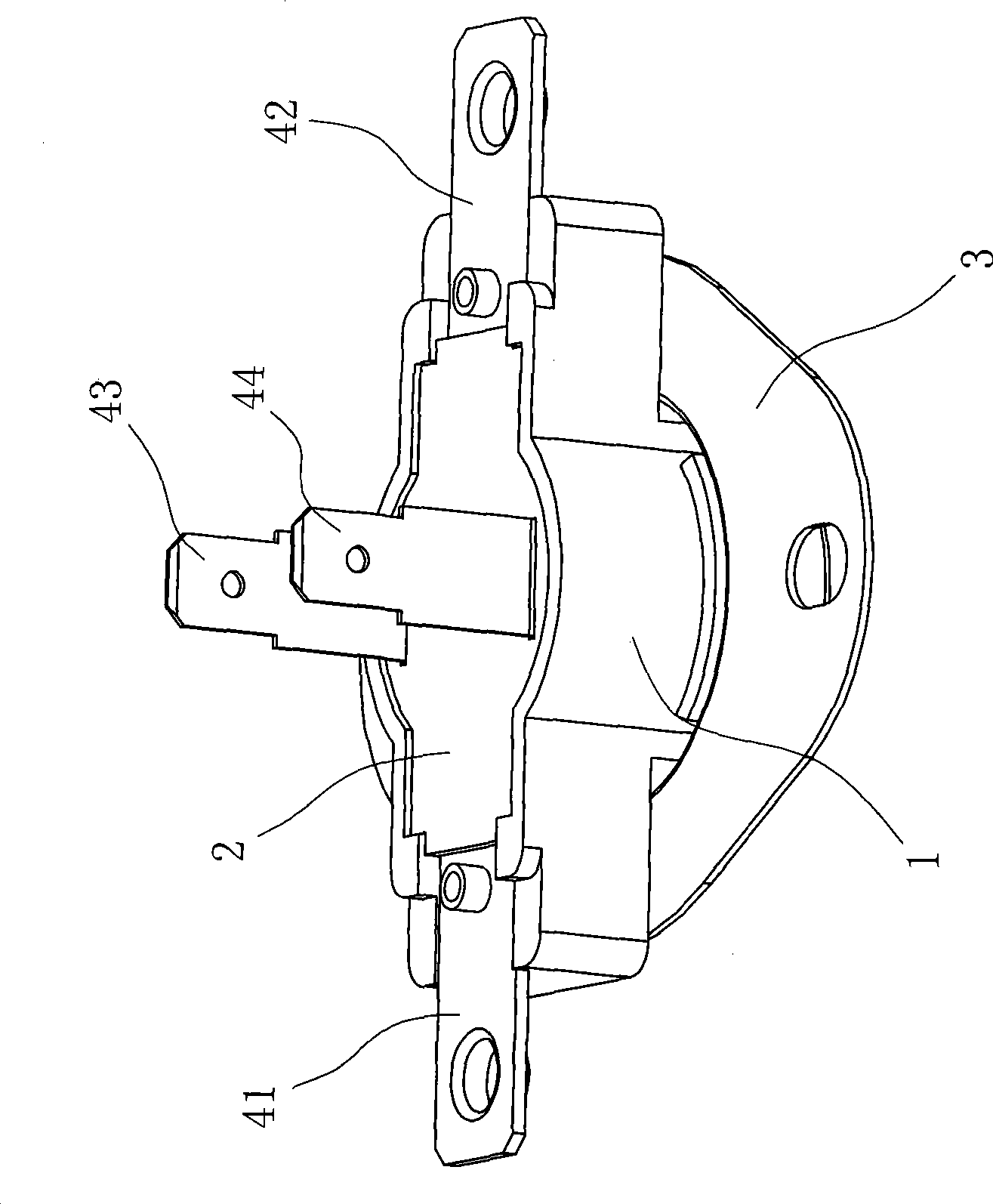

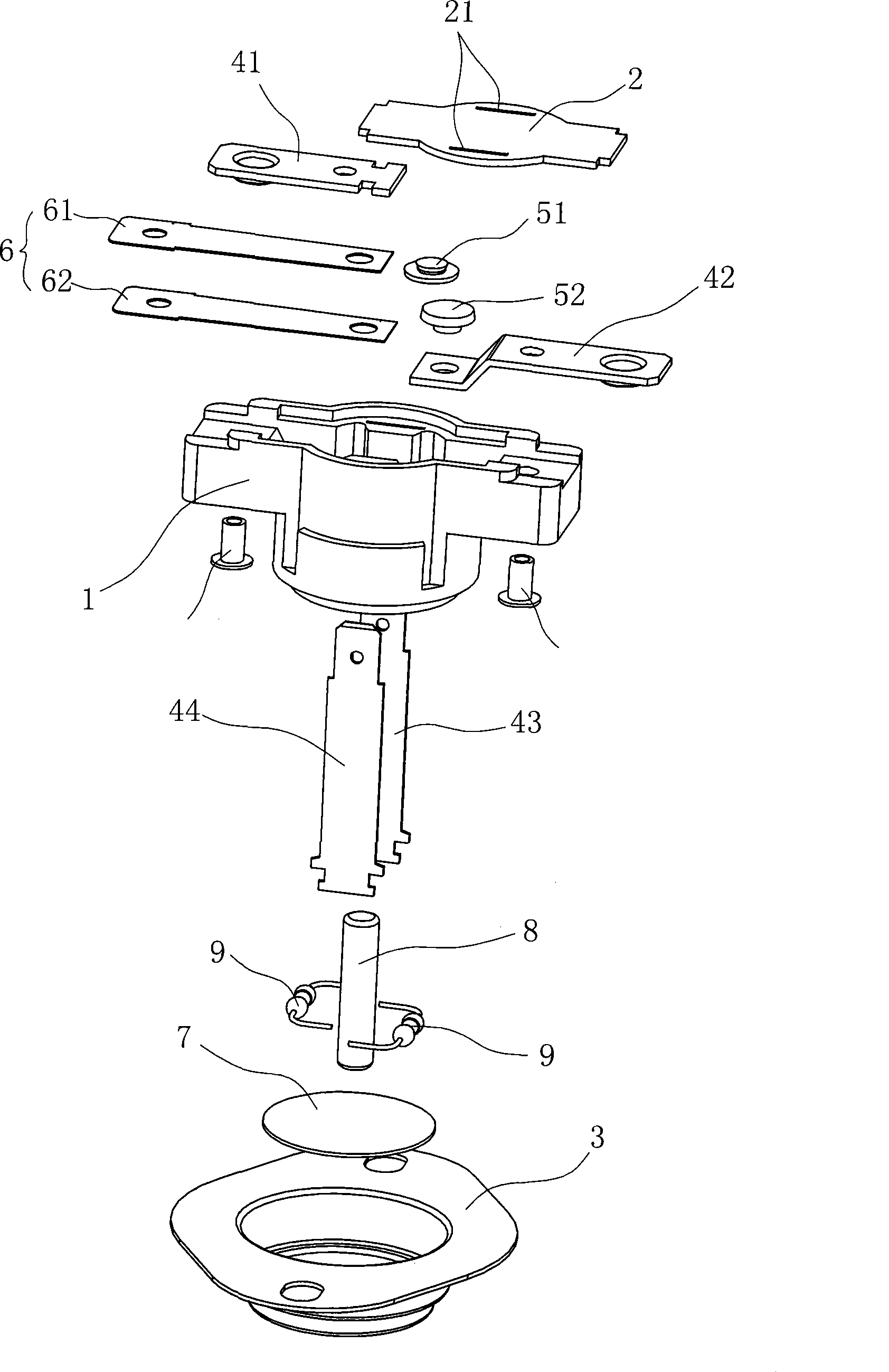

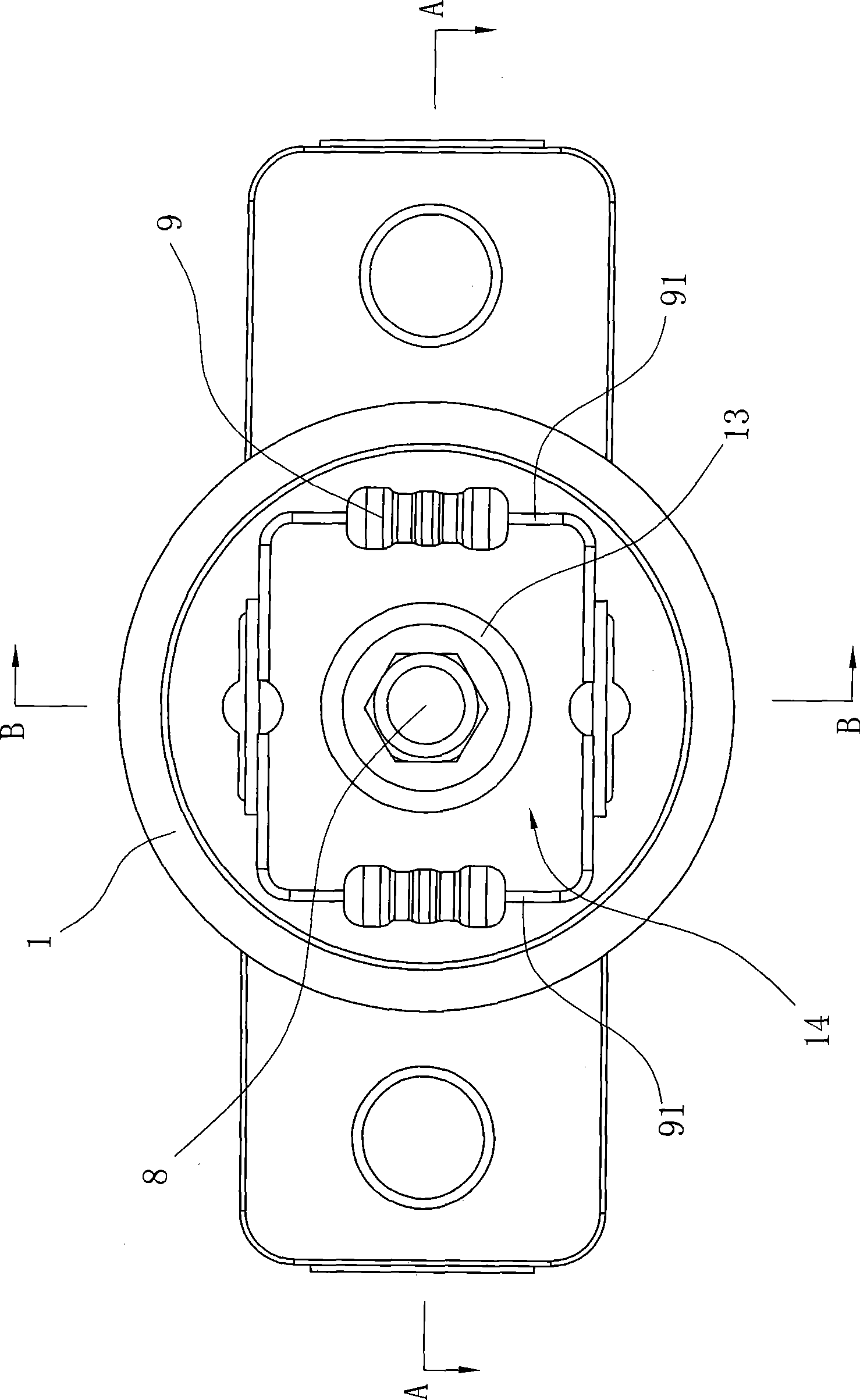

[0029] The temperature controller of the present invention is applicable to boilers, water heaters, vacuum cleaners, copiers, electric furnaces, ovens, clothes dryers, refrigerators, air conditioners, air compressors and the like. Such as Figure 1 to Figure 8 As shown, it is a specific embodiment of the present invention applied to a clothes dryer: including

[0030] The ceramic shell 1, which can withstand a higher heating temperature than the bakelite shell, is provided with a slidable push rod 8 for pushing away the contacts.

[0031] The bottom cover 2 is connected to one end of the housing 1 to seal the end face of the housing 1 , and the housing 1 is provided with a chamber 11 on the side where the bottom cover 2 is connected.

[0032] The top cover 3 is connected to the other end of the housing 1. The top cover 3 is a temperature-sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com