Coating composition for forming low-refractive-index layer, antireflective film using the same, and image display device including the antireflective film

A coating composition, low refractive index layer technology, applied in anti-reflection coatings, coatings, instruments, etc., can solve problems such as other processes, coating solution problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

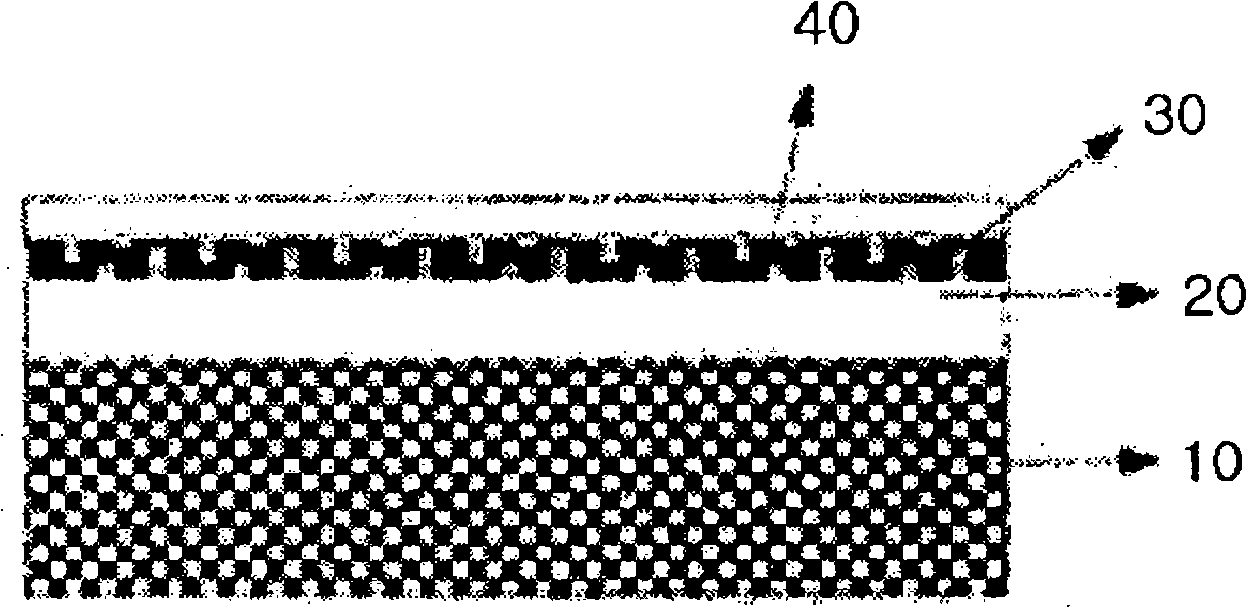

Image

Examples

preparation Embodiment 1 to 18

[0088] Preparation Examples 1 to 18: Preparation of Coating Solution for Formation of Low Refractive Index Layer

[0089] As the fluorine compound of Chemical Formula 1, R represented by (a) in Chemical Formula 2 is used f and have R represented by (e) in Chemical Formula 2 f (Preparation Examples 1-6), the fluorine compound of Chemical Formula 1 and the fluorine compound of Chemical Formula 3 (Preparation Examples 7-18) were used. As shown in Table 1 below, reactive silicon compounds and (meth)acrylate compounds were used, an example of which is urethane acrylate oligomer (Ebecryl 5129, available from SK-UCB). The various components were dissolved in a methyl ethyl ketone solvent and then mixed, after which the solid content of the composition was controlled to 5 parts by weight using a solvent mixture of methyl ethyl ketone and methyl isobutyl ketone. A photoinitiator, Irgacure 127 (commercially available from Ciba-geigy), was added in an amount of 5 parts by weight base...

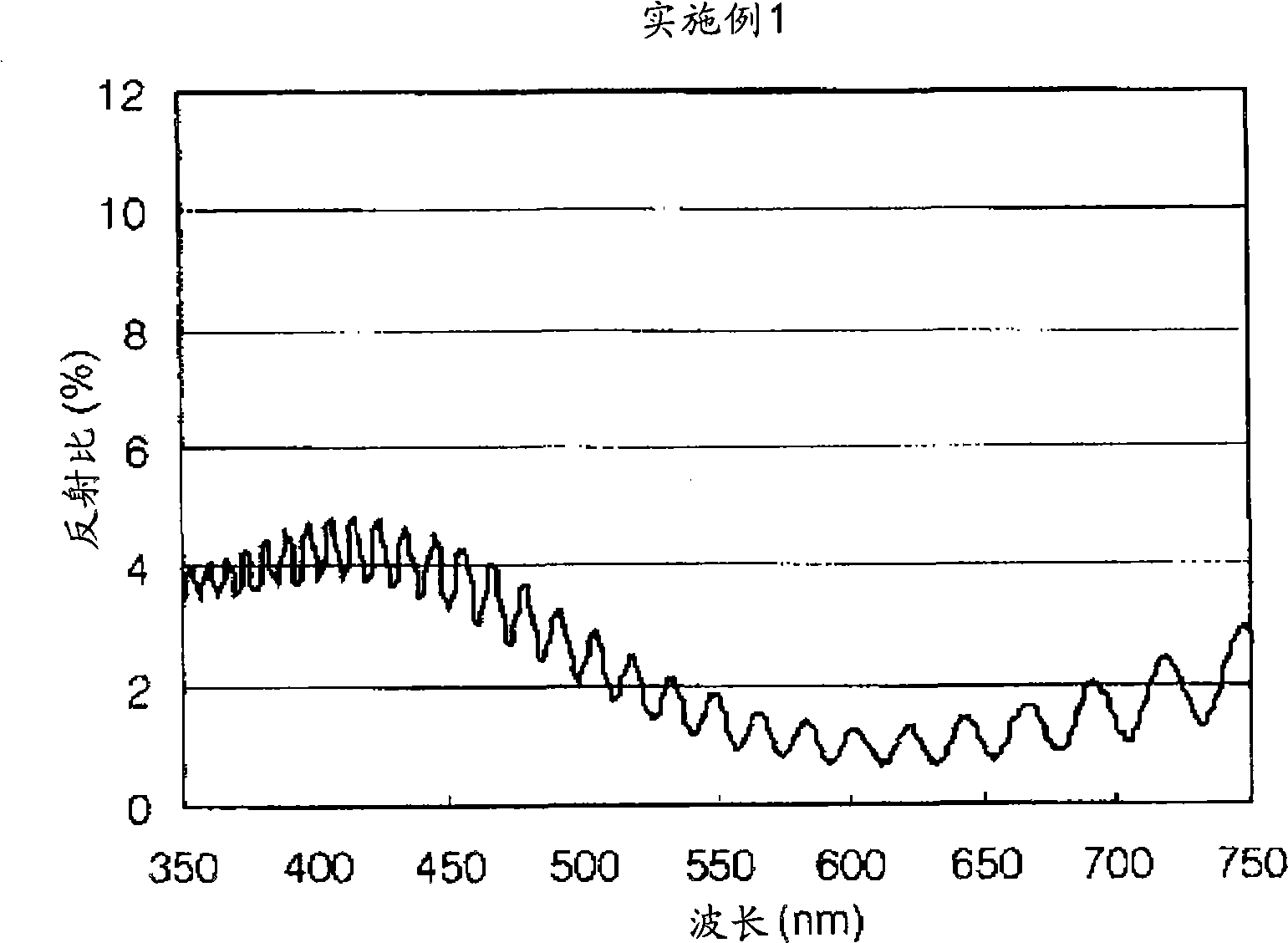

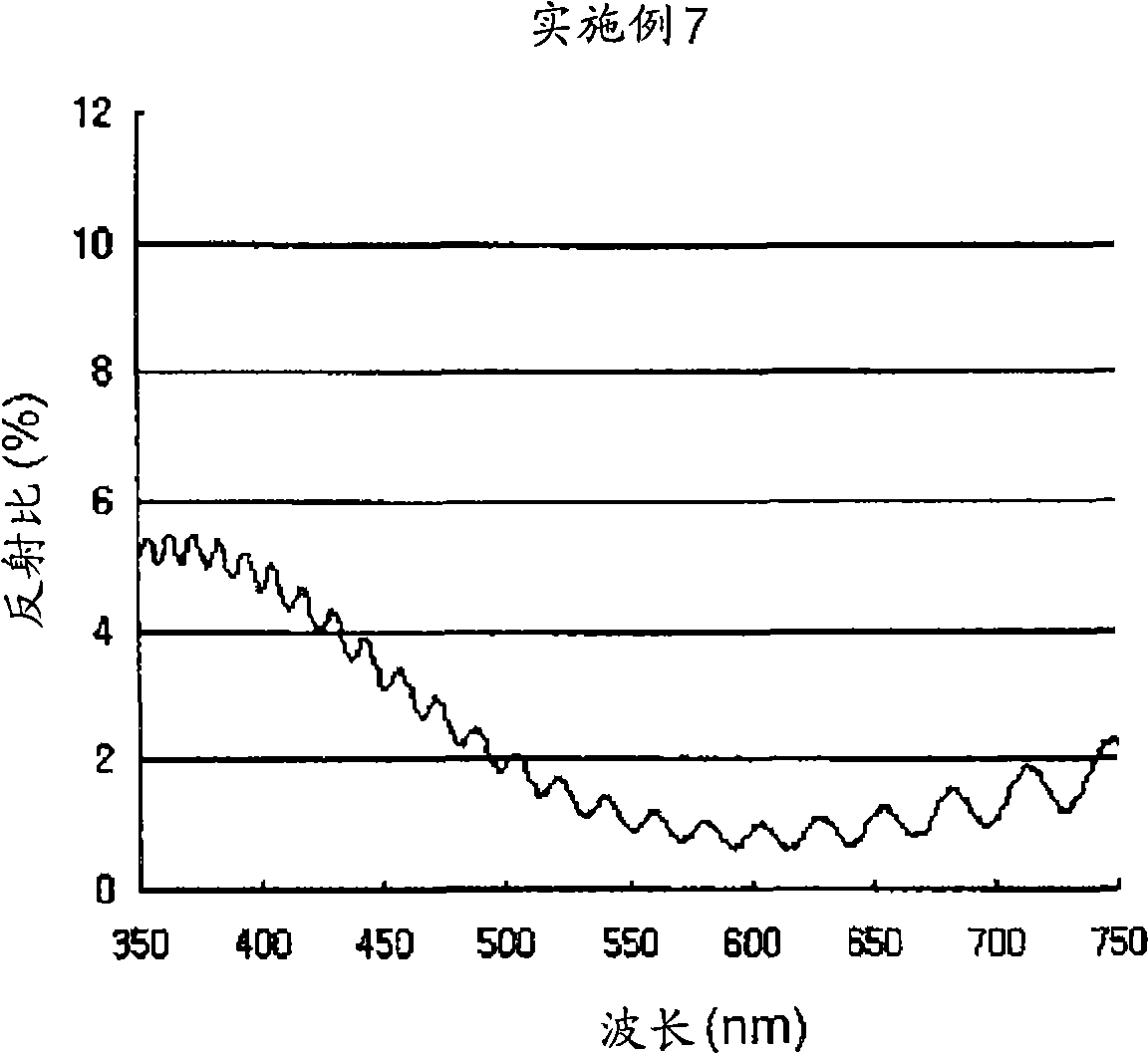

Embodiment 1 to 12

[0090] Embodiment 1 to 12: the making of anti-reflection film

[0091] 1) Substrate

[0092] As a substrate, a PET film (A4300, available from Toyobo) having a thickness of 100 mm was used.

[0093] 2) Formation of hard coating

[0094] 30 parts by weight of urethane acrylate oligomer (Ebecryl 5129, available from SK-UCB) and 20 parts by weight of dipentaerythritol acrylate (A-400, available from Nippon Kayaku) with 25 parts by weight of each of Mix methyl ethyl ketone and toluene. A photoinitiator, Irgacure 184 (available from Ciba-geigy), was added in an amount of 1 part by weight based on the total weight of the solid content of the composition.

[0095] Use a #12 bar as a bar applicator to form a coating film, dry at 80°C for 2 min to remove the solvent, and then irradiate at 300mJ / cm 2 Cured by UV light.

[0096] 3) Formation of high refractive index layer

[0097] A dispersion of tin oxide (available from Catalysts & Chemicals Ind Co. Ltd.), wherein tin oxide par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com