Fiber-optical zonal core thread

A technology of core wire and optical fiber, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of deterioration and enlargement of polarization mode dispersion, and achieve the effect of dispersion suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

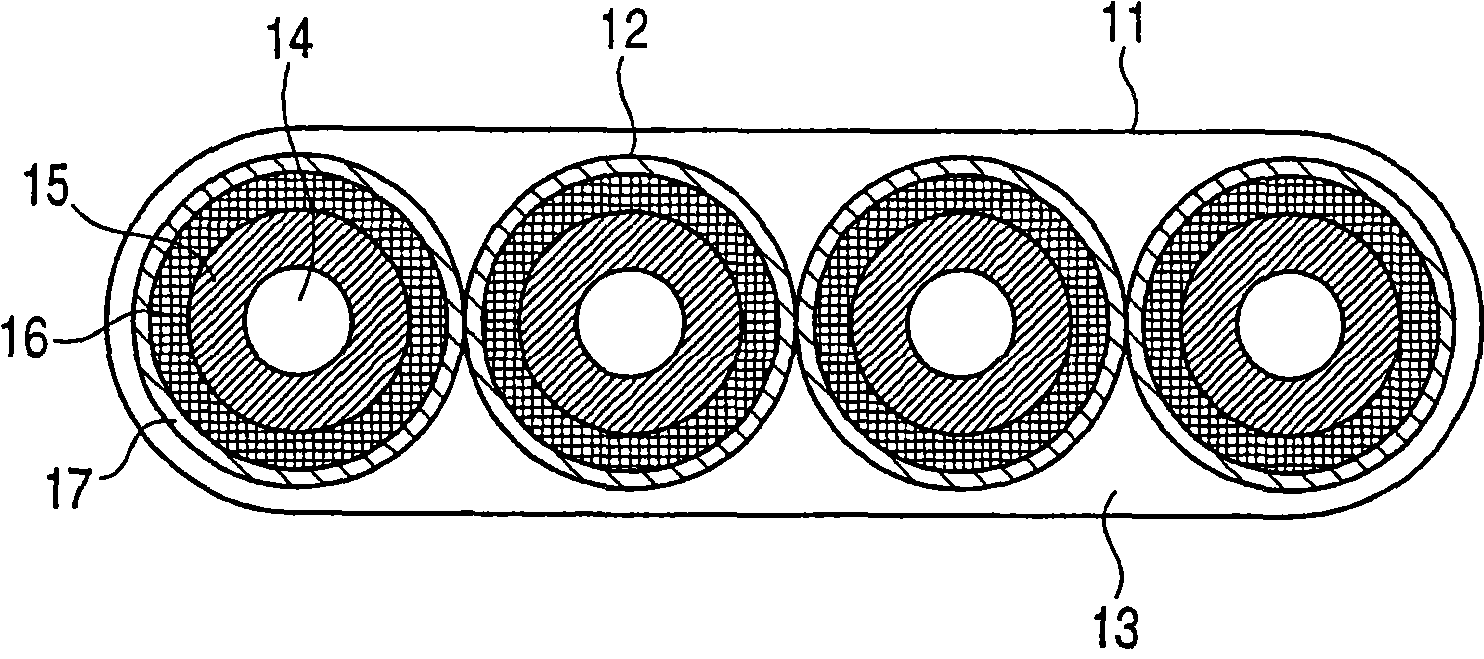

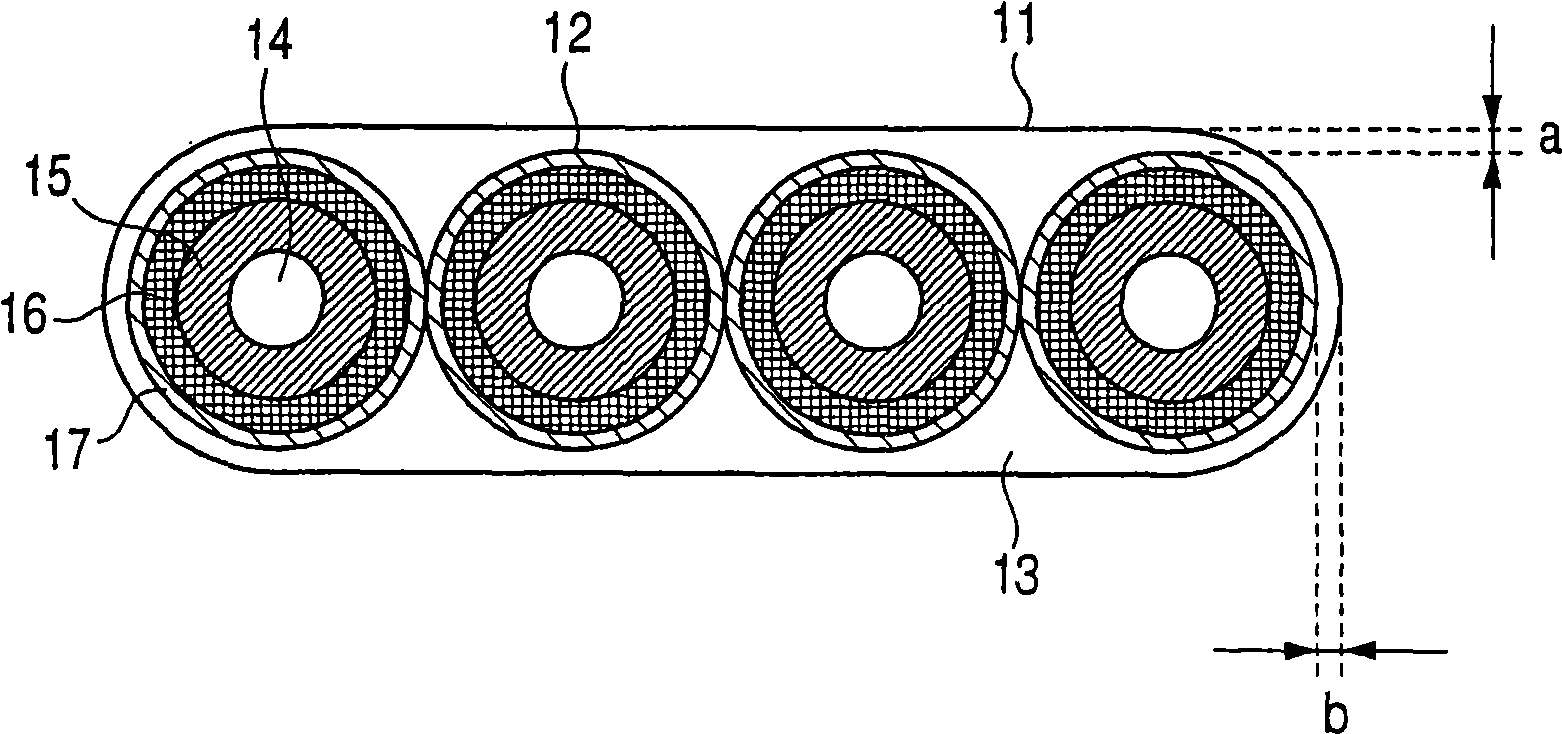

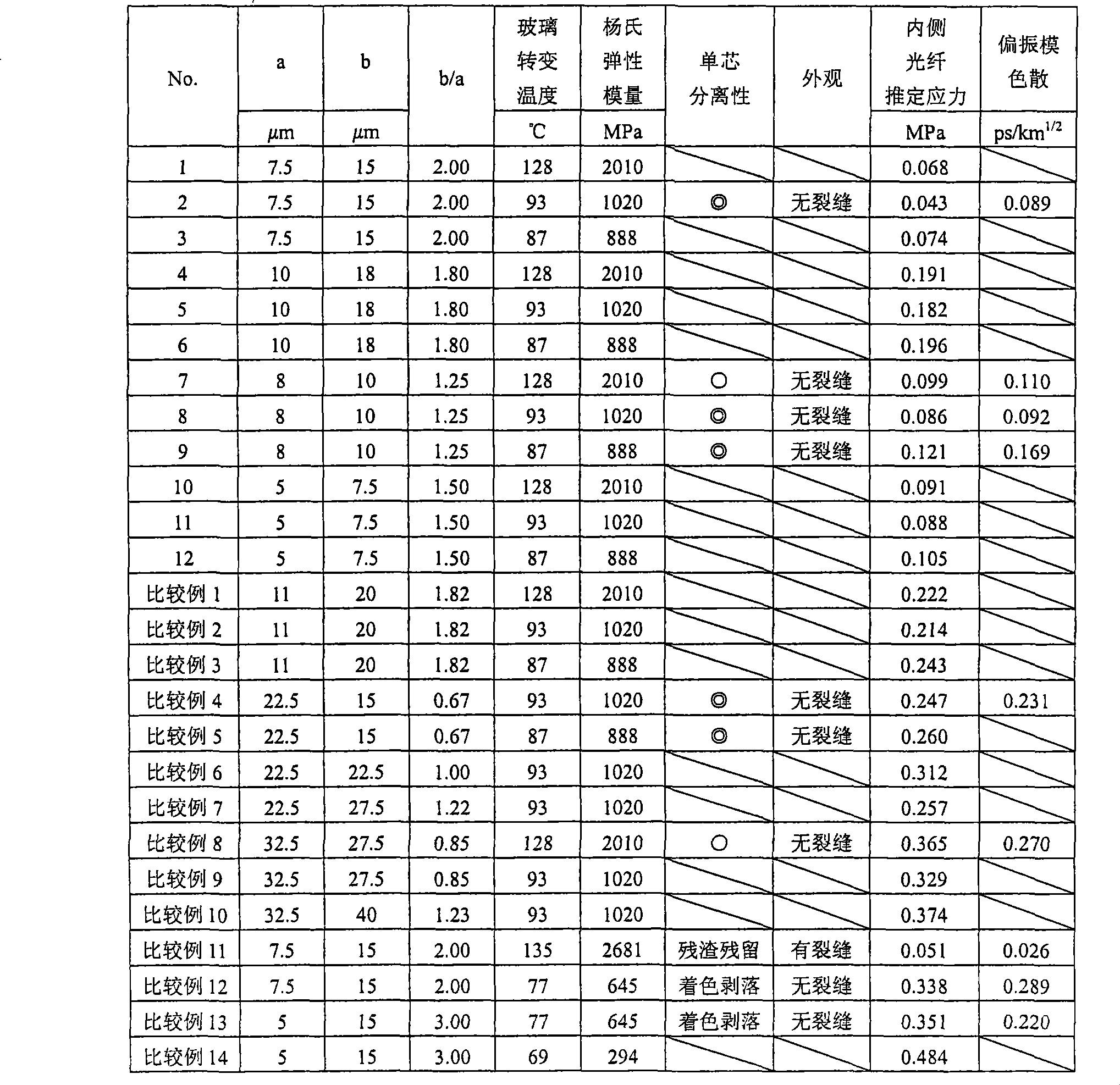

[0023] Embodiments of the present invention will be described with reference to the drawings. One embodiment of the optical fiber ribbon of the present invention has figure 1 The cross-sectional configuration shown. Such as figure 1 As shown, the optical fiber ribbon 11 is composed of an optical fiber core 12 and a ribbon resin 13 . The optical fiber core includes a glass fiber 14 made of quartz-based glass, a primary coating 15 , and a secondary coating 16 . The optical fiber ribbon 11 has a structure in which a plurality of optical fiber core wires 12 are arranged in a ribbon shape to be integrated, the optical fiber core wires 12 are arranged in a mutual contact or non-contact state, and the ribbon-shaped coating layer 13 These core wires 12 are collectively covered. Furthermore, figure 1 In the middle is an optical fiber ribbon in which the optical fiber cores are in contact with each other, indicating that the optical fiber core 12 is a 4-core ribbon.

[0024] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com