Instant dispersion capsule of tobacco flavor and preparation method thereof

A technology for tobacco flavors and dispersions, applied in the field of tobacco flavors and fragrances, can solve the problems of large loss and change of flavors and flavors, and achieve the effect of easy crushing and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described below.

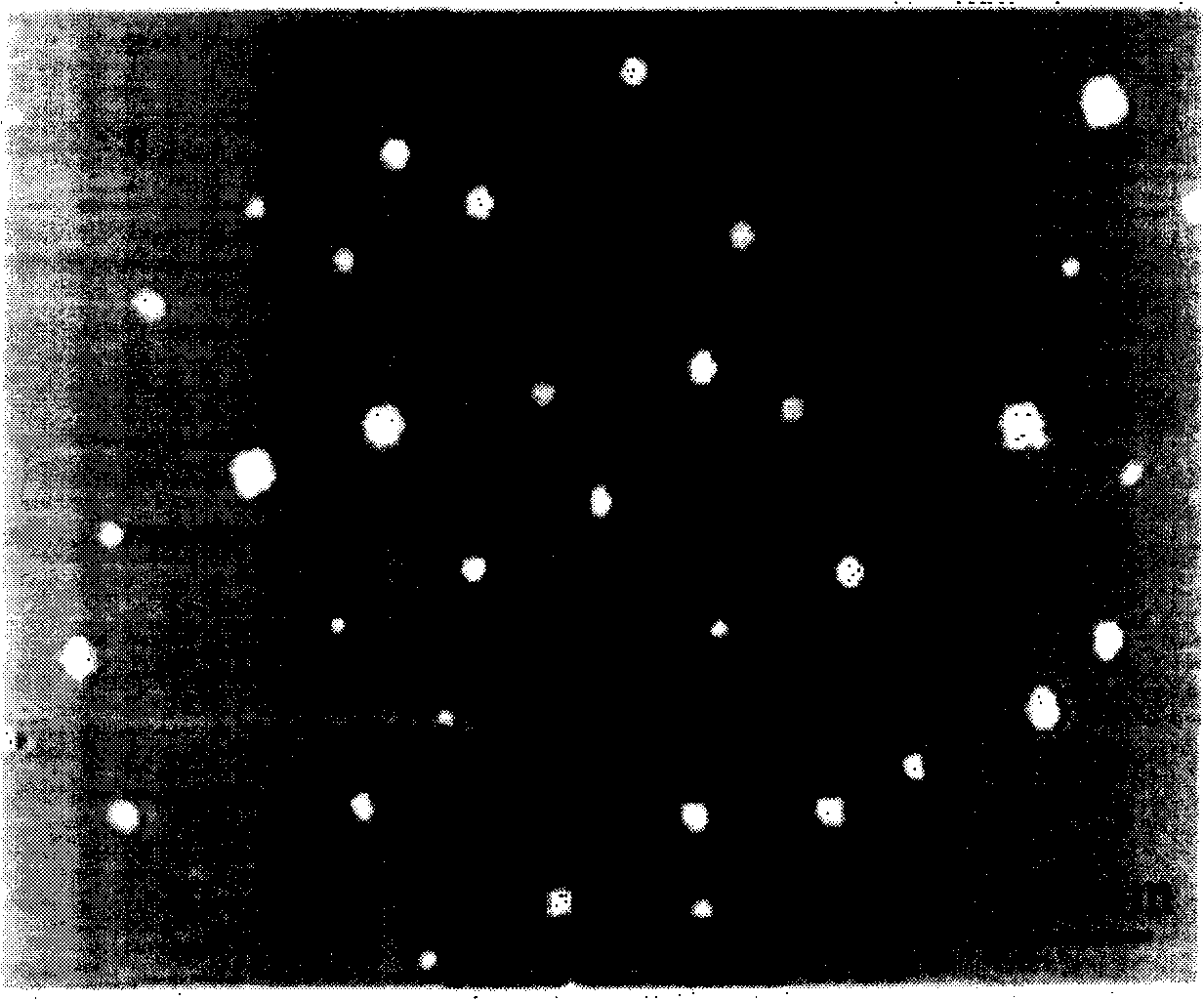

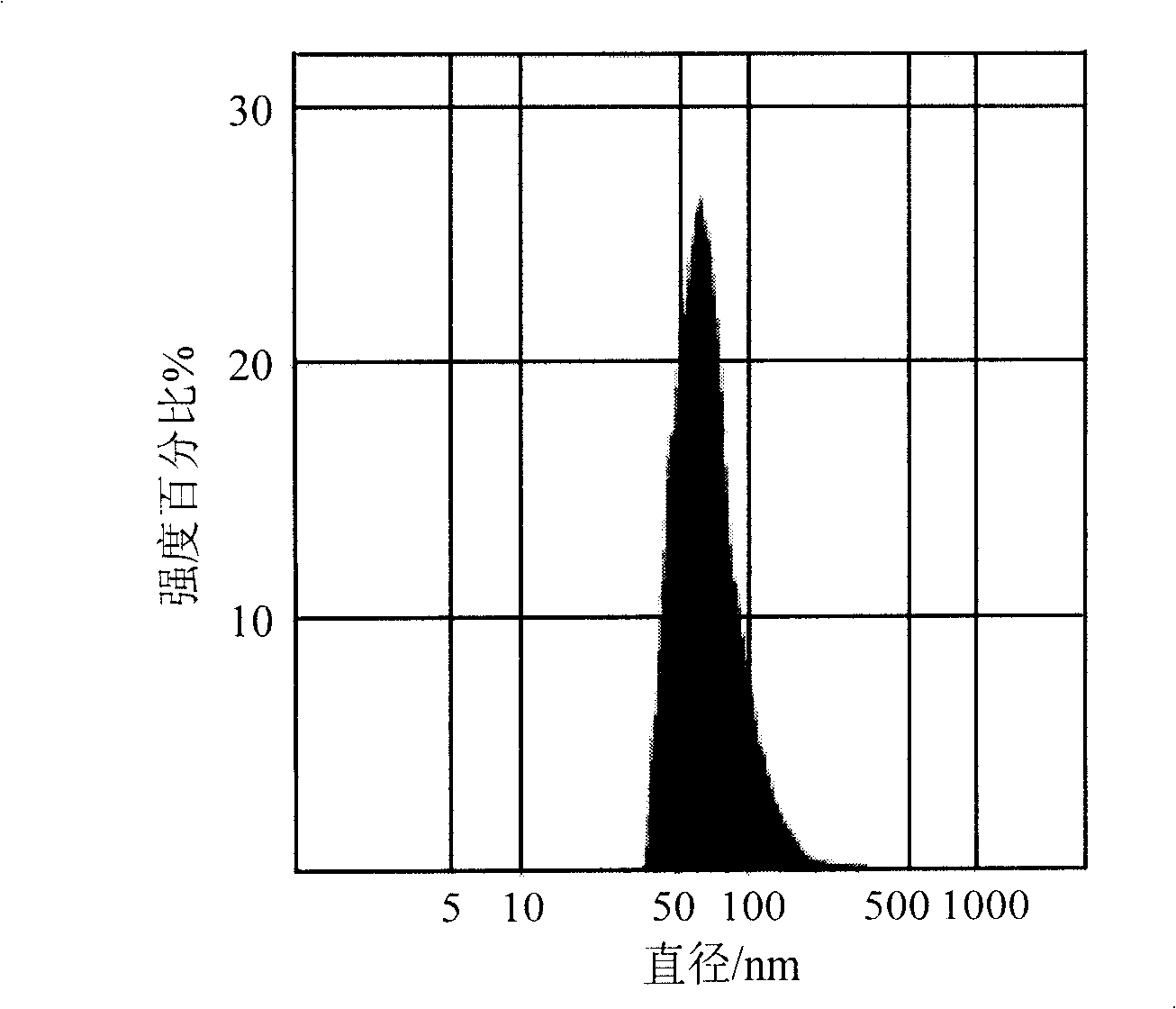

[0015] Take a certain amount of polyethylene glycol (PEG) 6000, heat it to 60-80°C to melt, and add a certain amount to the melted polyethylene glycol according to the requirements of the cigarette grade (the mass ratio of polyethylene glycol can be 5-10%) Tobacco essence, stir while adding, to form a uniform blend of essence and polyethylene glycol, cool and solidify naturally or put it in a freezer to accelerate cooling and solidification, grind and pulverize to nano-sized particles with an ultra-fine pulverizer, and then obtain tobacco Capsules with fragrance polyethylene glycol nanodispersion. The average particle size and particle distribution of the nano-dispersion capsules are measured by a Malvren Zetasizer3000 HS analyzer: the formed instant nano-dispersion capsules of tobacco flavor are generally spherical, with good particle dispersibility and no agglomeration, with a size of 50-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com