Heat flow heater with wall insulating property

A thermal insulation performance, heater technology, applied in the direction of ohmic resistance heating, heating or cooling equipment, electric heating devices, etc., can solve the problems of excessive volume, small heat leakage performance, poor heat insulation, etc., and achieve small weight and volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

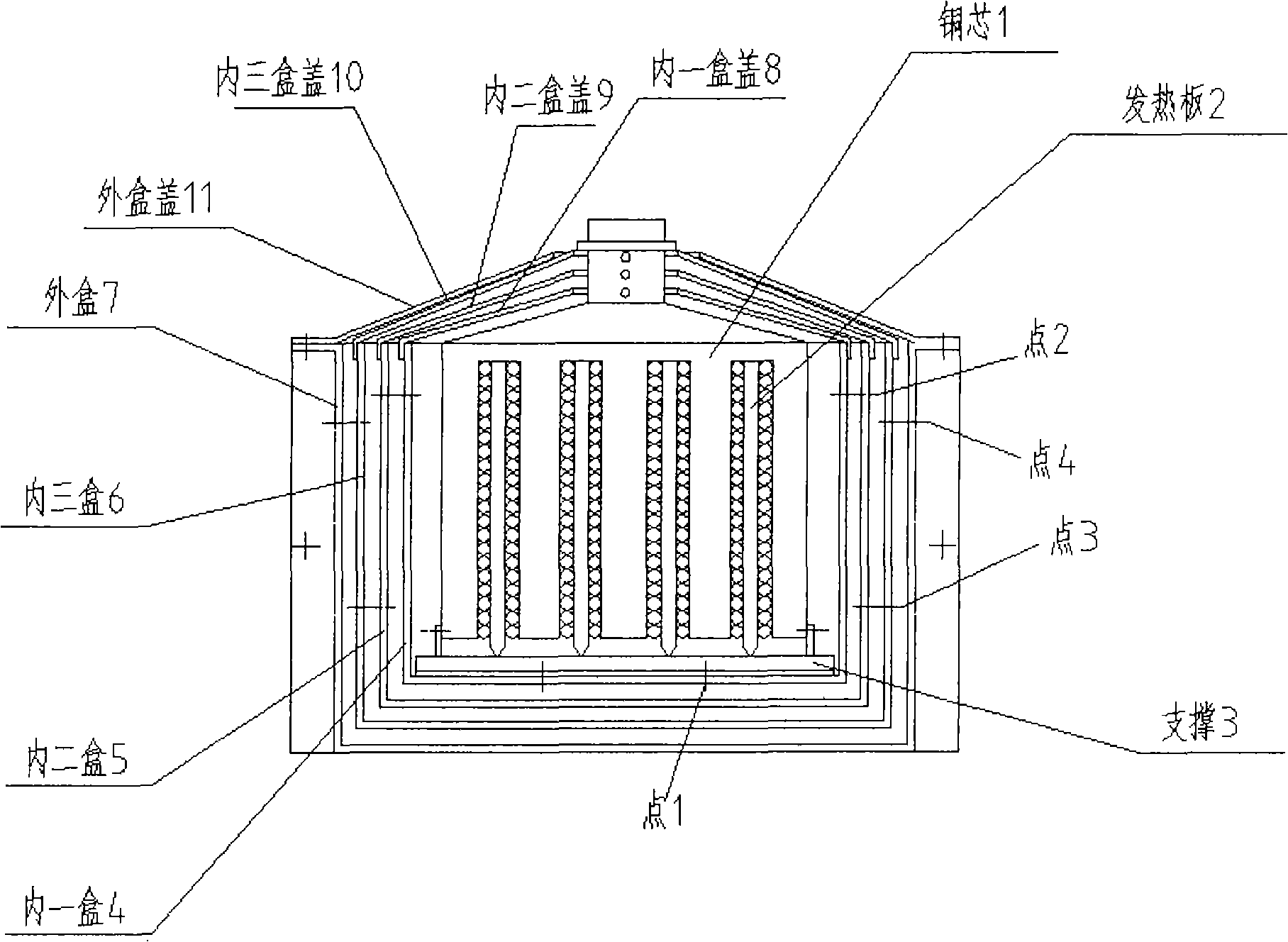

Embodiment Construction

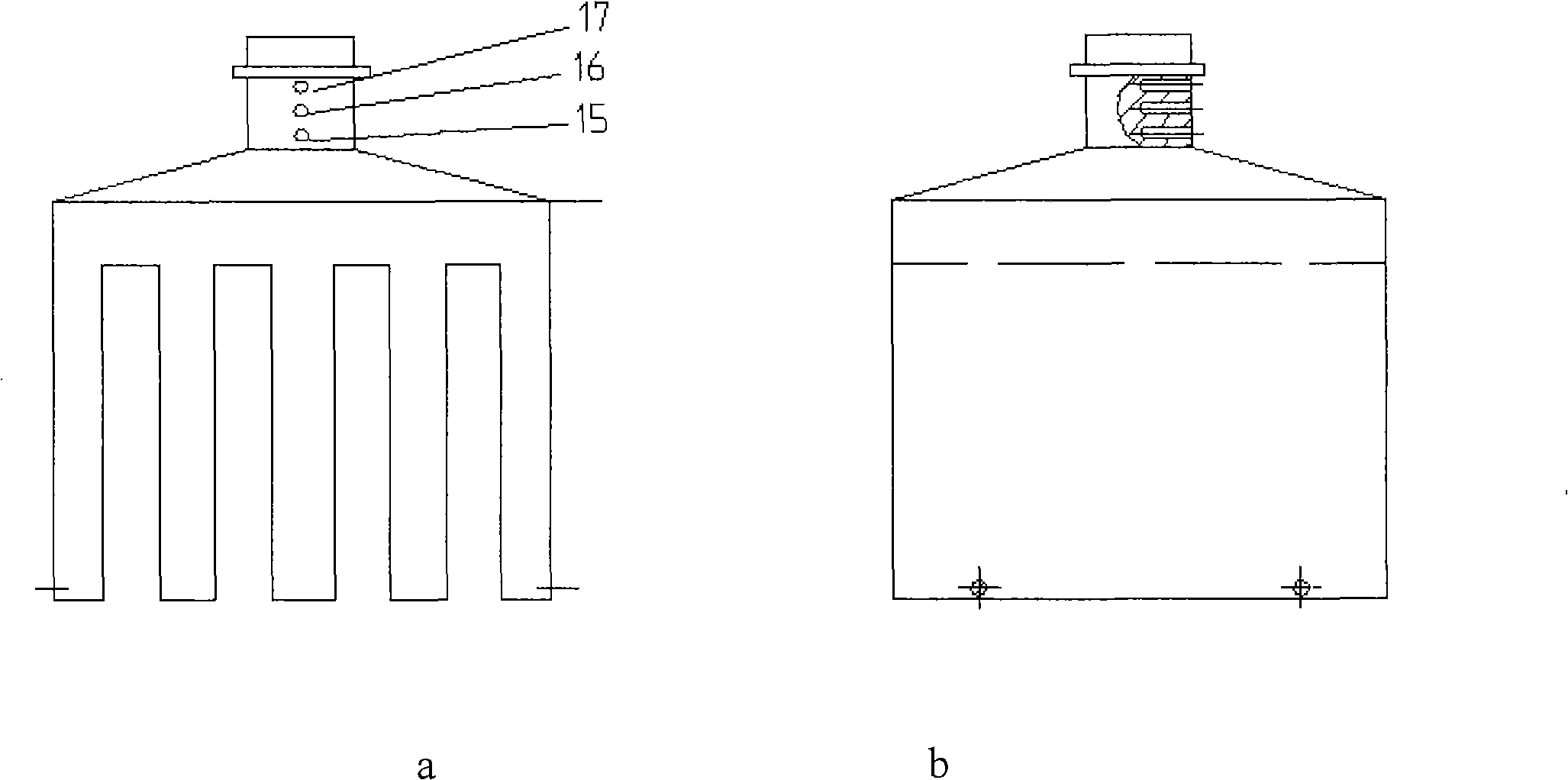

[0031] The high heat flux heater of the present invention adopts the long heat conduction path mode of bolts at different positions. In order to illustrate the effect of the present invention, it is now compared with a known straight-through bolt at the same position to further illustrate the inventiveness of the present invention. Figure 4 a is a straight-through bolt or metal column of known technology, Figure 4 b is the long heat conduction path of bolts or metal columns at different positions in the present invention. In both cases, heat leakage from the core heat source temperature T through three ways 芯 to ambient temperature T 环 , when the core temperature and ambient temperature are the same, the amount of heat leakage depends on T 4 the size of. The analysis of the three heat leakage mechanisms is as follows:

[0032] 1) Heat conduction: According to Fourier's law, Figure 4 heat leakage of a structure Figure 4 Heat leakage of b structure

[0033] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com