Direct-liquid type pen ink sac

A technology of direct liquid and ink sac, which is applied to ink pens with ink storage tubes in the pen holder, other ink pens, ballpoint pens, etc., which can solve problems such as poor hand feeling, increased manufacturing difficulty, and poor control of ink filling time, etc. problems, to achieve flexible and reliable automatic sealing performance, reasonable inner cavity space layout, and avoid the effect of residual ink splashing and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

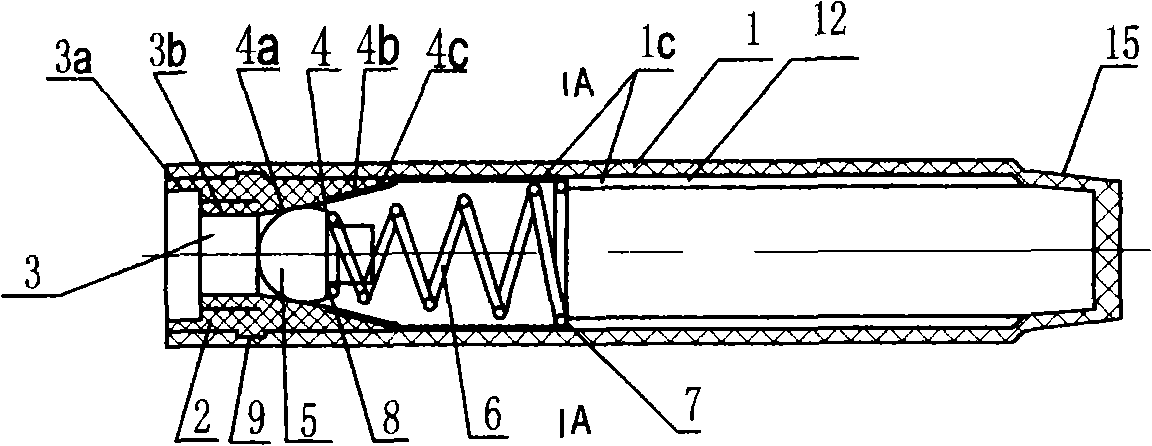

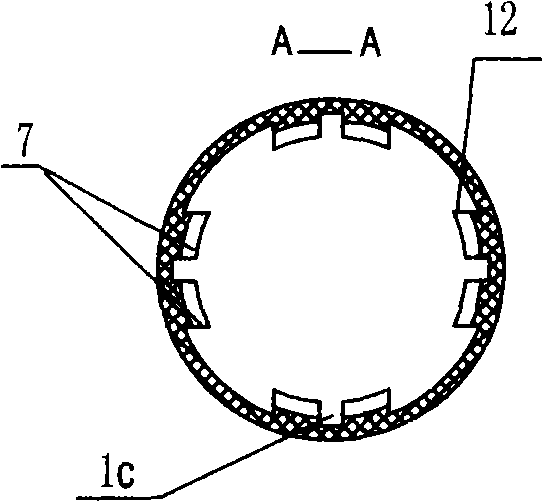

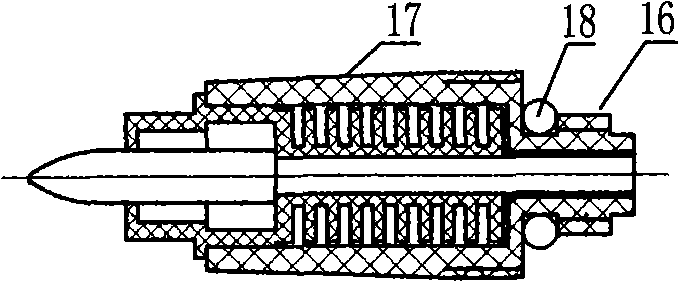

[0030] figure 1 , figure 2 Ink sacs for direct fluid pens shown, image 3 Shown is the cross-sectional structural diagram of the direct liquid type writing item assembly matched with the present invention

[0031] The ink bag for the straight liquid type pen is composed of the bag body 1, and the item matching hole 3 that is matched with the matching section 17 of the straight liquid type writing item assembly 16 is provided at the outlet of the inner cavity of the bag body 1, and the item matching hole 3 inside is located at the inside of the item matching hole 3. The valve matching hole 4 is located in the inner cavity of the capsule body 1 and the valve matching hole 4 constitutes a valve 5 that is in tight fit. On the surface of the inner cavity of the capsule body 1, an elastic seating surface 7 is formed, and a spring is arranged in the inner cavity of the capsule body 1. 6. One end of the spring 6 rests on the spring seat surface 7, and the other end of the spring 6 ...

Embodiment 2

[0037] Figure 4 1. The shown ink bag for a straight liquid pen, compared with embodiment 1, is different in that (1) the outlet of the inner cavity of the bag body 1 is integrated. (2) The bullet seat surface 7 is arranged on the convex surface 15 of the bottom cover 14 . The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0039] Figure 5 Compared with embodiment 1, the shown ink bag for straight liquid pen is different in that (1) the outer side of the stepped surface 3a of the capsule body 1 item matching hole 3 is provided with a section of threaded section 3e, and the threaded section 3e is connected with the pen item Corresponding thread matching connection on the top, the ink bag of this structure doubles as the pen holder, and the ink can be directly filled inside, and can also be repeatedly filled with ink, and the manufacturing cost and writing cost are mostly low; The cavity capacity is also correspondingly larger, so that more ink can be filled or the corresponding length of the capsule body can be reduced; a section of tapered surface 3d is provided on the inner side of the step surface 3a, and the tapered surface 3d and the tapered surface on the pen item play an auxiliary seal and push open valve 5. effect. The rest of the structure is similar to that of Embodiment 1, and will no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com