High-speed railway and wheel-rail train

A high-speed rail and train technology, applied in the field of rail transportation, can solve the problems of high-speed stability and reliability taking a long time, incompatibility with each other to connect the transportation network, pantograph and catenary wear, etc., to shorten the construction time. , the structure is simple, the effect of reducing the cost of infrastructure construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

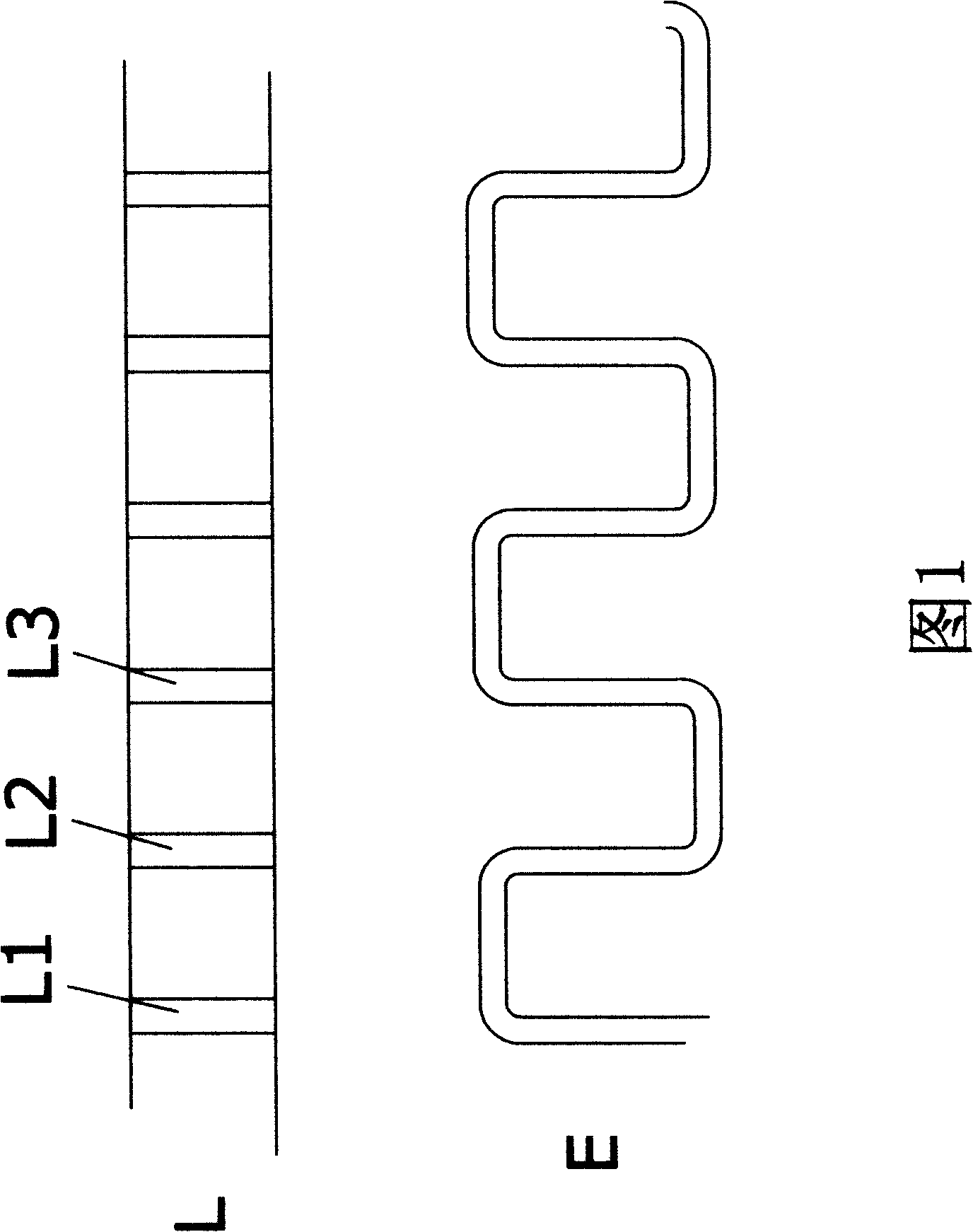

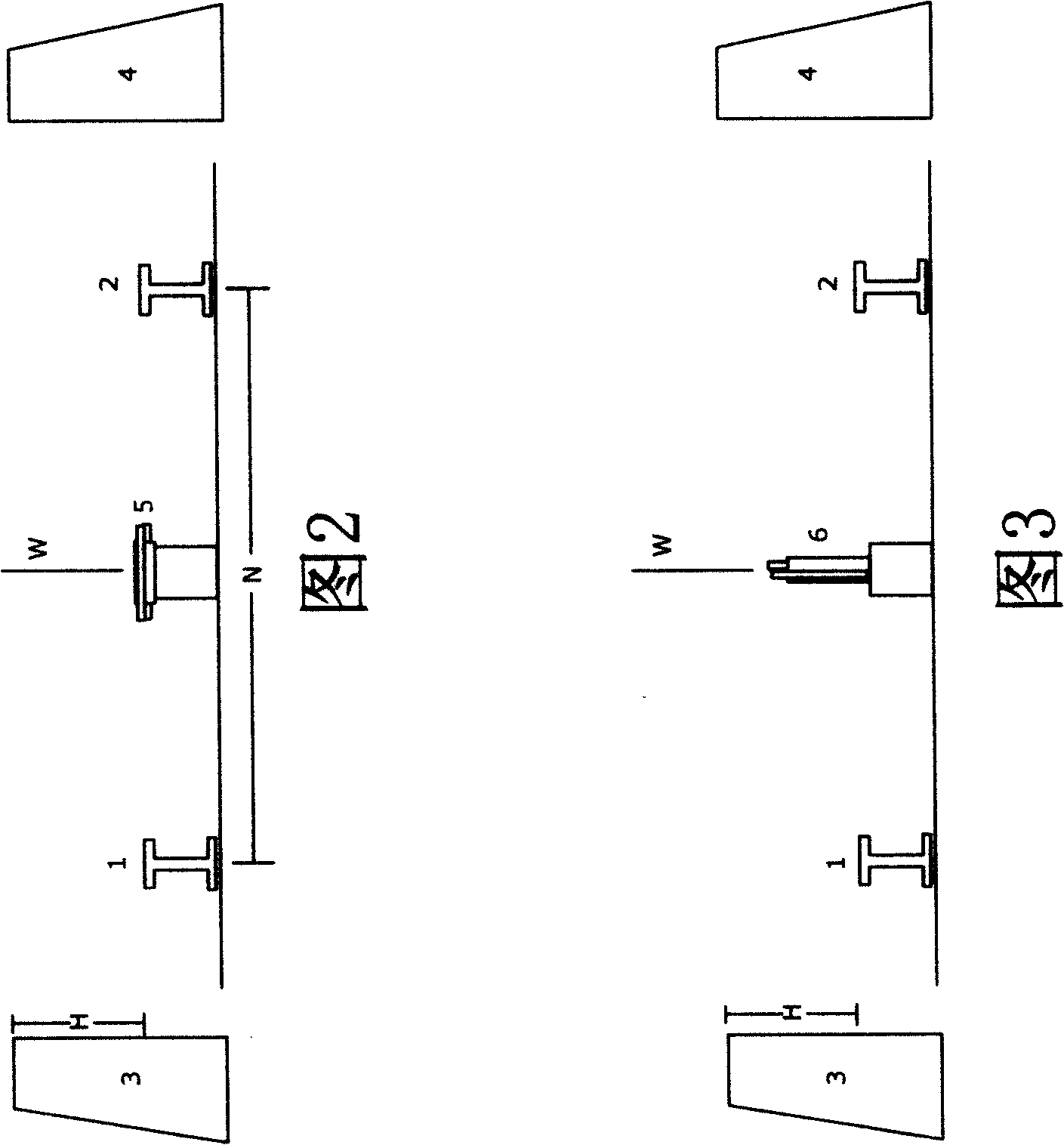

[0046] A preferred high-speed rail implementation such as image 3 shown. A plurality of winding supports (L) arranged in a row having slots (L1, L2, L3...) substantially equidistant from one another perpendicular to the longitudinal direction, the wires of at least two linear motors being elongated in a zigzag shape The stator winding (E) is partly arranged in the slots (L1, L2, L3...) of the winding support (L) to form a long stator track (6). There is a long stator track (6) in the high-speed track The middle part between the metal rails (1, 2). The virtual plane (W) is the plane of symmetry of the two metal rails (1, 2), which is not a physical plane, and the slots (L1, L2, L3...) on the long stator track (6) are basically parallel to the plane of symmetry (W). Long stator windings (E) and winding supports (L) see figure 1 .

Embodiment 3

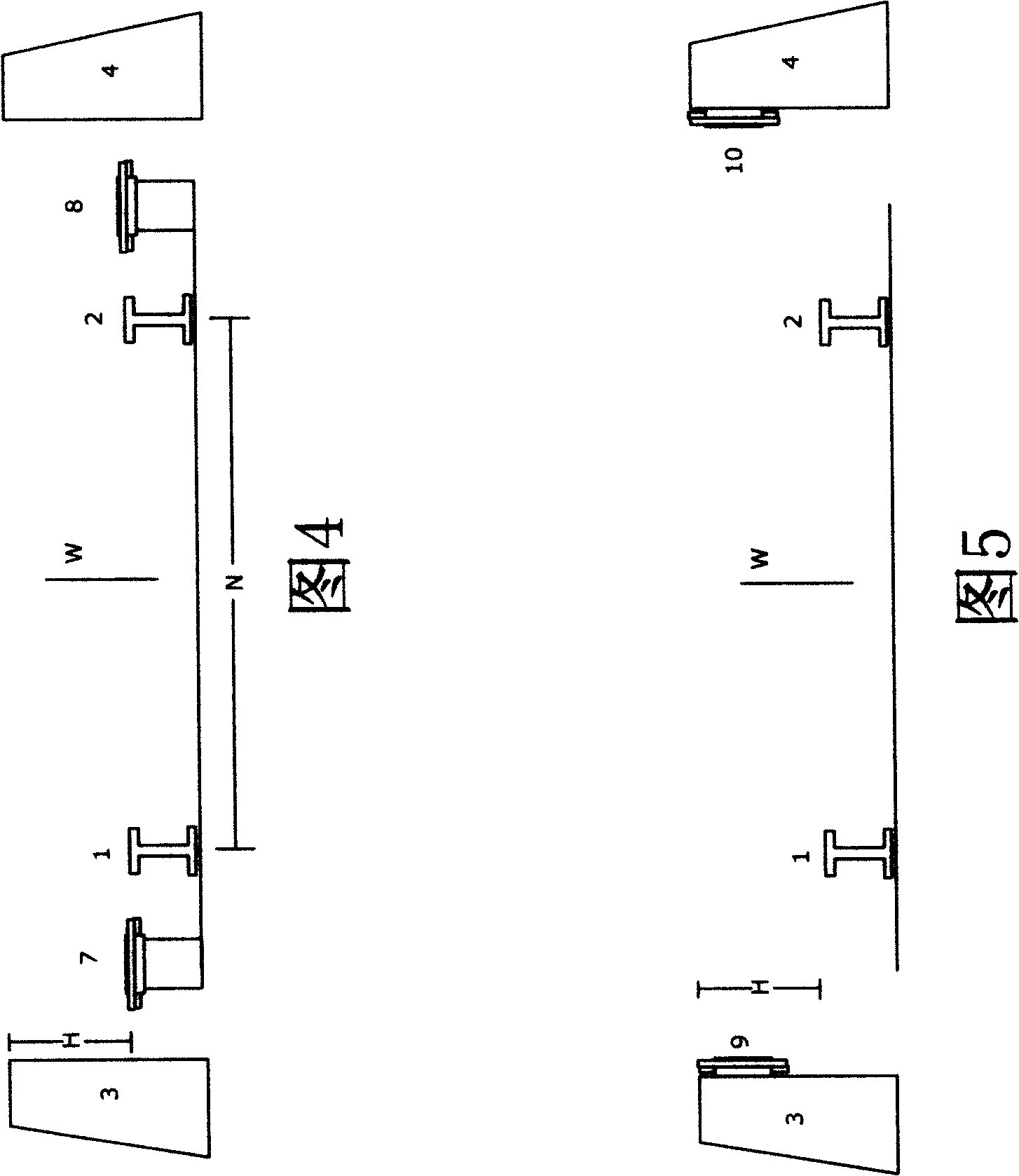

[0048] A preferred high-speed rail implementation such as Figure 4 shown. A plurality of winding supports (L) arranged in a row having slots (L1, L2, L3...) perpendicular to the longitudinal direction and substantially equidistant from each other, at least one wire of a linear motor in a zigzag shape around a long stator Windings (E), and partly arranged in the slots (L1, L2, L3...) of the winding support (L) to form long stator tracks (7, 8). The virtual plane (W) is the symmetric plane of the two metal rails (1, 2), which is not a physical plane. There are two long stator rails (7, 8) in the high-speed rail which are basically symmetrical with respect to the virtual plane (W). The slots (L1, L2, L3...) on the long stator rails (7, 8) are substantially perpendicular to the imaginary plane (W). Figure 4 (7, 8) is the outer side close to (1, 2), and may also be the inner side close to (1, 2). Long stator windings (E) and winding supports (L) see figure 1 .

[0049] High-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com