Method for preparing a cannon-cleaning device using abrasive flows

A technology of abrasive flow and abrasive materials, which is applied in the direction of weapon cleaning devices, grinding/polishing equipment, grinding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0038] 1, for the smooth-bore artillery of 100mm in diameter, use the silicon carbide of 70# as abrasive grain, carrier selects silicon rubber for use, and it is mixed with silicon carbide according to the ratio of 1.5: 1 and is mixed with the abrasive material that gun barrel is wiped;

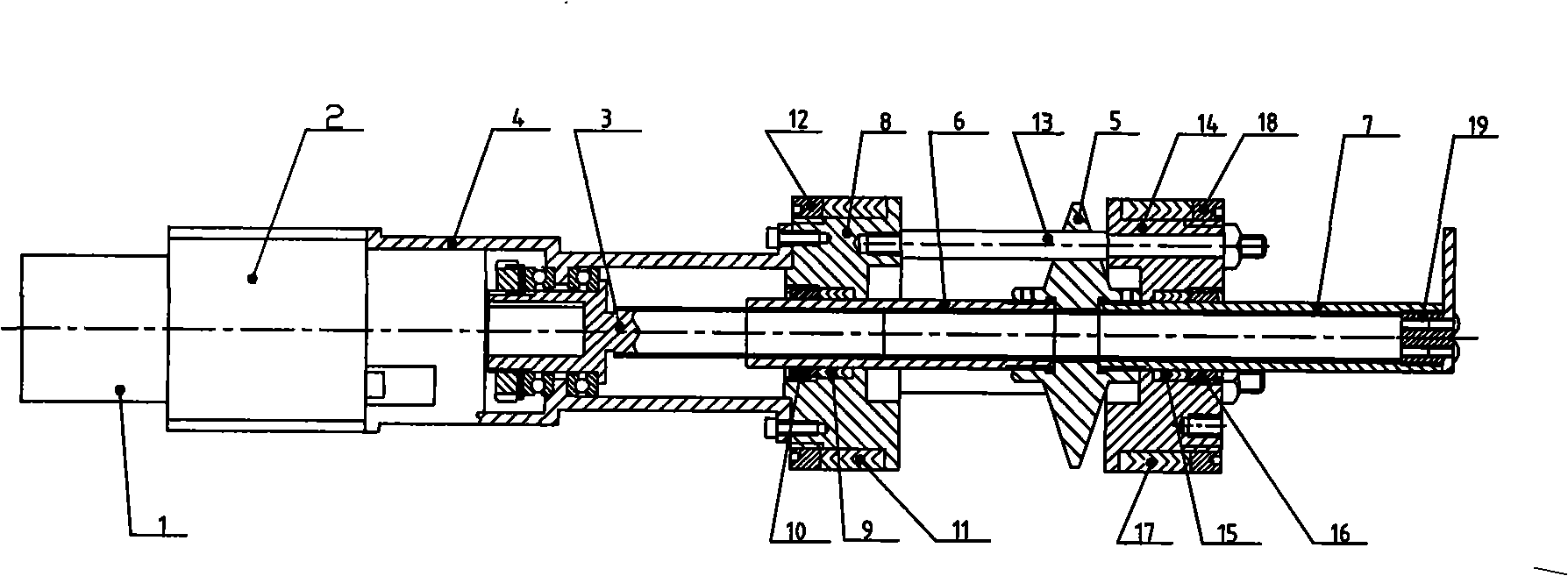

[0039] II. Preparation of the Abrasive Flow Scrubbing Device Assembly

[0040] Firstly, select the stepping motor of RORZE brand model M26A33S, and connect the stepping motor 1 and the harmonic reducer 2 fixedly to form the stepping motor harmonic reducer assembly A. Then, connect the pushing cake 5 to the nut sleeve respectively 6 and the guide sleeve 7 are riveted together in sequence, and the front seal seat 8 is put on the outer side of the nut sleeve 6, and the V-shaped clamp for the piston rod is sequentially inserted into the gap between the front seal seat 8 and the nut sleeve 6 from the inside to the outside. Fabric combined sealing ring 9 and inner sealing pressure ring 10, on the out...

Embodiment approach 2

[0050] For smooth-bore guns with a caliber of 100mm, 70# silicon carbide is used as the abrasive grain, the carrier is silicon rubber, and it is mixed with silicon carbide in a ratio of 2:1 to make the abrasive for gun barrel wiping; the RORZE brand model is The stepper motor of M26A33S, the diameter of the pusher cake 5 is designed to be 98mm, the diameter of the front seal seat 8 and the rear seal seat 14 is designed to be 98mm, and the diameter of the outer sealing pressure ring 12 and the outer sealing pressure ring 18 is 99mm. The diameter of the V-shaped clamp fabric combined sealing ring 11 and the V-shaped clamp fabric combined sealing ring 17 for the piston rod is 100mm. Others are the same as Embodiment 1.

Embodiment approach 3

[0052] For smooth-bore guns with a caliber of 120mm, 70# silicon carbide is used as the abrasive grain, the carrier is silicon rubber, and it is mixed with silicon carbide in a ratio of 2.5:1 to prepare the abrasive for barrel wiping; the RORZE brand model is selected as The stepper motor of M29B26S, the diameter of the pushing cake 5 is designed to be 118mm, the diameter of the front seal seat 8 and the rear seal seat 14 is designed to be 118mm, and the diameter of the outer sealing pressure ring 12 and the outer sealing pressure ring 18 is 119mm, and the diameter of the piston rod is The diameter of the V-shaped clamp fabric combined sealing ring 11 and the piston rod V-shaped clamp fabric combined sealing ring 17 is 120mm. Others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com